Types of Bridges and Sound Wave (Acoustic Emission) Bridge Wire Break Monitoring System

Bridges are vital infrastructure that require constant attention to ensure their safety. Our bridge monitoring system uses advanced acoustic emission technology to detect structural defects early on, avoiding costly downtime and, most importantly, keeping people safe. Trust our condition monitoring solutionsfor reliable performance and peace of mind.

Bridges are an integral and important part of the road system and are of strategic importance in the transportation industry, so ensuring the safe condition of bridges is of great concern. Suspension bridges, cable-stayed bridges and other bridges that need to be tensed by cables are also faced with the risk of fatigue or even break during long-term use. Periodical shutdown bridge detection is not a good choice because of the busy traffic, so a system that can carry out long-term monitoring during the service of Bridges has great advantages. Experimental investigation shows that acoustic emission is the best technology to detect bridge wire break. It can not only carry out sensitive and accurate long-term monitoring, but also it is a non-intrusive method. RAEM1 acoustic emission monitoring system developed by Qingcheng AE Institute is the latest product based on Linux operating system. It can accurately monitor the broken signal of the bridge wire, calculate the wire break rate, and trigger the alarm to the operator when the broken wire limit is exceeded, so that maintenance plans can be made in advance to ensure the safe service of the bridge.

Bridges, from Sydney Harbor to the Tower Bridge across the Thames to the Golden Gate, connect us and bind us together. They’re gateways to discovery — and the way many of us get to work each day. Whether they’re simple footbridges, functional toll bridges, or complicated drawbridges, they all serve an essential function.

Bridges can be the simplest structures or huge, stunning works of art — or anything in between. As long as it gets us across a span that would otherwise be difficult (or even impossible) to cross, a bridge serves its singular purpose.

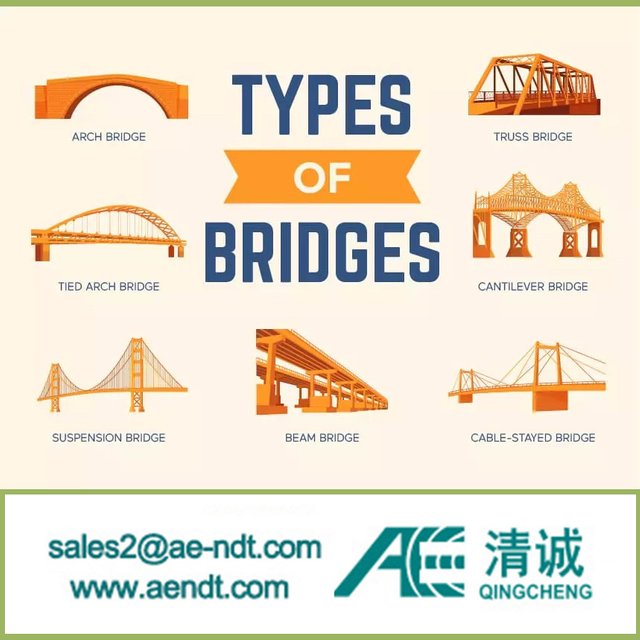

7 Different Types of Bridges

Arch Bridge

Beam Bridge

Cantilever Bridge

Suspension Bridge

Cable-Stayed Bridge

Tied-Arch Bridge

Truss Bridge

Beginning with the first tree trunk laid across a creek bed, humans have created increasingly sophisticated bridge designs through the ages. Innovation has resulted in different structures and types of materials used to span waterways and canyons.

Now it’s common to see massive, intricate modern bridges that span shockingly long distances. The world’s longest bridge, the $8.5 billion Danyang-Kunshan Grand Bridge in China, carries a high-speed railway more than 100 miles.

Bridges work by balancing the forces of physics through a superstructure (girders, trusses, etc.), which bears the bridge deck and its load, and a substructure (pillars, abutments, piers, and footings), which grounds the load into the earth.

A bridge needs to resist movement so it can provide a stable surface to cross a divide. Correct engineering and bridge construction can strike the perfect balance to keep a bridge standing.

- ARCH BRIDGE

The Romans built more than 1,000 stone arch bridges, some of which still survive, such as the Pont-Saint-Martin bridge in Italy’s Aosta Valley (built in the first century BCE). This bridge design dates back more than 3,000 years. Concrete is now also used to build modern arch bridges.

A bridge’s load is the weight of the bridge itself (called the dead load), combined with the weight of whatever it carries (the live load). An arch bridge uses the forces of load and gravity, which otherwise might send a bridge tumbling downward, to hold it up instead.

An arch bridge works by conveying the downward pressure of gravity inward to the center of the structure — toward a central stone called the keystone — rather than straight down. This principle is called compression, and it enables the arch below to support the surface, or deck, above it.

Fixed arch bridges can be destabilized by temperature fluctuations, so the arch design is sometimes modified with hinges at each base and even the center of the span. This helps longer arch bridges adapt to the expansion or contraction of their materials when temperatures change drastically.

- BEAM BRIDGE

The simplicity of the beam bridge made it the first type of bridge ever built. It’s still the cheapest to build. All you need is a crossbeam covering the span, supported by an abutment at each end. One type of beam bridge is a girder bridge, which employs steel girders as reinforcement.

Gravity is a bigger challenge when constructing a bridge because, unlike a building, most of what’s underneath is empty space. A beam bridge might be supported only by two abutments, one at either end, to counter gravity and bear the entirety of its load.

But here’s the danger of beam bridges: The longer a bridge is and the more people, cars, and other things it carries, the heavier its total load. And the farther apart a beam bridge’s abutments are, the less stable the structure is.

By adding supports in the middle, known as piers or stanchions, and connecting sections between them, you can create a very long, stable bridge. Examples are the 3.2-mile Yolo Causeway near Sacramento, California, or the 24-mile Lake Pontchartrain Causeway in Louisiana.

In beam bridges, the force of compression pushes the load inward onto piers at the middle of the bridge. Simultaneously, the pulling or stretching force of tension pulls the load outward toward the abutments at both ends of the bridge.

- CANTILEVER BRIDGE

Some bridges are built using cantilever construction. This type uses a pillar anchored vertically into the ground to support a horizontal deck extending out from one or both sides across the span. The load often is supported from both above and below. A diving board or platform is a good example of cantilever construction.

The world’s longest cantilever span belongs to the Quebec Bridge in Canada, which was built in 1919 and extends 1,800 feet. It surpassed the length of the Forth Bridge in Scotland, which was completed in 1890.

In the U.S., the central section of Conde B. McCullough Memorial Bridge over Coos Bay in Oregon is a cantilever. So is the eastern section of the San Francisco-Oakland Bay Bridge (not to be confused with the Golden Gate). Many cantilever bridges are combined with other types to cross a single span.

Cantilever bridges are often supported with trusses. A bridge truss takes the load off the deck and transfers it to the supporting piers and abutments, helping the cantilevers withstand tension in the upper supports and compression in the lower ones.

(Read more on truss construction below, in the section on truss bridges.)

- SUSPENSION BRIDGE

A suspension bridge is perhaps the most recognizable bridge type in the United States, thanks to the iconic Golden Gate Bridge in San Francisco. Completed in 1937, it draws more than 10 million visitors each year to marvel at its twin 746-foot orange towers and sweeping Art Deco effect.

Suspension bridges are just what their name sounds like: They’re stabilized with vertical pillars or pylons connected by suspension cables. Attached to these main cables are smaller, vertical suspenders that hold up the bridge deck using tension, the main force that sustains suspension bridges.

Though the first suspension bridges were made of simple ropes supporting wooden planks, now the suspension technique supports long spans over broad channels. But because these bridges are only fixed to the earth in a couple of places (the towers or pillars), they can sway in the wind or vibrate when crossed by heavy traffic.

Wind or movement across a bridge can create vibrations. When these reach a certain frequency, it can cause a dangerous phenomenon called resonance — the same principle that causes a glass to shatter if a trained singer hits a high enough note. If vibrations are intense enough, they can disrupt bridge crossings and cause a collapse.

Suspension bridges also can be affected by torsion, a twisting force often caused by environmental factors like wind, which can create dangerous movement. If the surface of a bridge twists enough while travelers are on it, they can be thrown off.

And while torsion creates stress on a vertical plane, shear imparts a similar effect horizontally. It happens when environmental forces put pressure in opposite directions on a single, fastened part of a bridge, breaking it like a stick between two hands.

- CABLE-STAYED BRIDGE

A cable-stayed bridge is a variation on the suspension bridge that connects the crossbeam or bridge deck directly to pillars or towers. There’s no main cable, just a large number of vertical suspenders affixed to the top of the tower. These suspenders use tension to help keep the bridge deck stable and in place.

The Strömsund Bridge in Sweden is considered the first modern cable-stayed bridge. The three-span structure was completed in 1956. Its steel and concrete deck is suspended by diagonal cables from two pylons.

The glass-decked Sundial Bridge, built in 2004 across the Sacramento River in Redding, California, makes use of the cable-stay technique in conjunction with elements of cantilever and suspension. The famed Brooklyn Bridge, which opened in 1883, is a hybrid cable-stayed and suspension bridge.

- TIED-ARCH BRIDGE (BOWSTRING)

A tied-arch bridge combines features of an arch bridge and a suspension bridge. It uses horizontal thrust from both sides to support an arched structure, as in a regular arch bridge. But instead of an arch supporting the structure from below, the arch rises above the road, and vertical ties descend to increase support of the decking.

These are also called bowstring bridges since they look like a bow from the side. This bow uses the tension of its vertical cables, together with the compression of the arch, to support the load and keep the bridge stable.

The wooden-decked Blackfriars Street Bridge in London, Ontario, Canada, is an example of this style. It carried vehicle traffic from the year it was built, 1875, until 2013, when it was permanently closed.

U.S. bowstring bridges include the Fort Pitt Bridge over the Monongahela River in Pittsburgh, the Lowry Avenue Bridge over the Mississippi River in Minneapolis, and the Daniel W. Hoan Memorial Bridge in Milwaukee.

A truss bridge distributes its load across a series of small sections fitted together. Formed by structural beams for smaller bridges or box girders for larger ones, bridge trusses are typically bound together by welded or riveted joints in a series of triangles.

Vertical steel or wooden supports help hold up the bridge using tension, while the diagonal truss supports add stability via compression, directing the load toward the center, similar to an arch.

The fairly inexpensive truss design has been around for a long time. Most truss bridges were built of wood in the 19th century, before a shift to iron and steel. The familiar Pratt truss design features diagonal segments that slope toward the bridge’s center. It was introduced by Thomas Willis Pratt in 1844.

The Cottonwood River Pratt Truss Bridge in Cedar Point, Kansas, is a classic example of this practical and widely used design. It was built in 1916 by the Missouri Valley Bridge Company and is on the U.S. National Register of Historic Places.

Other kinds of truss designs include:

Baltimore truss

Howe truss

Long truss

Vierendeel truss

Warren truss

The Ikitsuki Bridge in Japan holds the world’s longest continuous truss span. Completed in 1991, it checks in at 1,300 feet. The Francis Scott Key Bridge over Baltimore Harbor is another notable example of this design.

Types of Bridges by Mobility

FIXED BRIDGES

Fixed bridges are pretty simple: They’re anchored in place and meant to provide a steady, secure passage across a river, canyon, rail line, roadway, or other obstacles. Many of the bridge styles described above are in this category.

I-beam girders can provide stability in beam bridges, such as highway overpasses, but box girders — enclosed tubes, usually rectangular — provide better protection against torsion.

TEMPORARY BRIDGES

Pontoon bridges are most commonly used in wartime to transport troops, supplies, and military vehicles. These are generally temporary structures that float directly on the water atop pontoons — containers filled with air to provide buoyancy.

They’re a successor to the ancient practice of lining up ships or rafts end-to-end to form a bridge. One drawback of pontoon bridges is that, because they rest directly on the water’s surface, they obstruct any watercraft trying to navigate the channel they cross.

MOVABLE BRIDGES

The category of movable bridges includes lifting and swinging bridges. These allow a portion of the structure to move out of the way and allow passage of tall ships in a waterway. Here are some examples:

A vertical lift bridge is a kind of truss bridge that’s raised using cables affixed to the deck. These allow it to be raised via pulleys attached to the top of a tower or pylon on either side of the waterway. The deck remains horizontal as it’s raised, and its maximum height is dictated by the height of the towers.

The deck on a bascule bridge, or drawbridge, by contrast, is lifted from the base, like a door swinging upward, often by hydraulics.

Swing bridges also allow watercraft to pass, but using a different method: They rotate horizontally, or swing like an opening door, on a pedestal. They’re not as common, but they are used occasionally in places too wide for a lift bridge.

Traverser bridges use cantilevers that can be rolled out over a channel on wheels or withdrawn, giving the effect of a platform moving horizontally.

Common Types of Bridges by Function

AQUEDUCT/VIADUCT BRIDGE

An aqueduct is a “water bridge” in Latin. The Romans used arched aqueducts to carry water from one place to another. A viaduct is a roadway elevated by a series of arches over an extended distance.

CULVERT

Culverts aren’t technically bridges, but they’re similar. Simple structures usually surrounded by soil or other fill, these allow water to flow underneath rather than across a road, trail, or rail line. They’re often made of concrete, but some are simple corrugated pipes.

DOUBLE-DECKED BRIDGE

A double-decked bridge can accommodate more traffic in densely populated areas. The Yangsigang Yangtze River Bridge in China, which opened in 2019 at a cost of $1.27 billion, is the longest double-decker suspension bridge in the world, at 5,500 feet.

Its upper deck features six lanes for each direction of freeway traffic, plus pedestrian footpaths and sightseeing areas to the sides. The lower deck carries another four local motor vehicle lanes, two lanes for non-motorized vehicles, and two more pedestrian walkways.

PEDESTRIAN BRIDGE

Footbridges, or pedestrian bridges, can be simple spans across canyons, streams, or roadways wide enough for a person (or two people side-by-side) to cross. The earliest bridges were stepping stones or fallen trees. This type also includes swinging bridges and boardwalks, which typically traverse lower, marshy, or sandy land.

PIPELINE BRIDGE

A pipeline bridge, as you might expect, is built to carry a gas- or liquid-bearing pipeline. These run through places where it isn’t possible to build the pipeline under a river or other obstacle. These are often suspension bridges.

TRAIN BRIDGE

Truss bridges became prominent in the 1800s, when railroads were the pinnacle of transportation, so it’s no surprise that many truss bridges carry rail lines. Another kind of train bridge is the trestle, which consists of multiple short beams end-to-end, supported by (often wooden) frames placed close together to cross a long span.

VEHICLE TRAFFIC BRIDGE

A traffic bridge is wide and sturdy enough for at least one vehicle to traverse in a single direction, although usually it accommodates at least two lanes of opposing traffic.

Types of Bridge Materials

Around the world, bridges are made of almost any material at hand, including ropes, vines, even trash. The following materials are the most common used in bridge building:

Wood — A popular material for trusses and trestles in the 1800s, wood was also used for covered bridges. Its use gave way to more durable options that weren’t susceptible to warping, splintering, and termites.

Stone — A low-maintenance and durable option often used for arched bridges, stone was often used for bridge-building in the Roman era.

Concrete and steel — In more modern times, a combination of concrete and steel is most often used for freeway overpasses, etc.

Advanced materials — Construction materials are evolving to respond to specific environmental conditions and cut down on maintenance. These include fiber-reinforced plastics, high-performance concrete, and composite materials.

Forces That Influence Different Bridge Designs

What determines the type of bridge that gets built in a particular place? Bridge designs are based on more than aesthetics. In addition to the topographical and logistical conditions where a bridge will be built, there are also natural forces to consider. Some of the forces of nature that act upon bridges are:

Gravity — The downward pull is a bigger deal with bridges than buildings. Unlike a home or a skyscraper, most of what’s under a bridge is empty space.

Load — The weight of the bridge itself is combined with the weight of whatever it carries. The longer a bridge is, and the more people, cars, and other things it carries, the heavier its load.

Compression — The pushing or squeezing force that creates inward movement toward the center, compression is what helps keep arched bridges standing. But with too much compression, a bridge can buckle.

Tension — In the opposite direction, tension is the pulling or stretching force that creates outward movement away from the center. Tension in vertical cables is what sustains suspension bridges. But with too much tension, a bridge can snap.

Torsion — This twisting force, often caused by environmental forces like wind, can cause dangerous movement in structures like suspension bridges. If the surface of a bridge twists enough while travelers are on it, they can be thrown off.

Shear — While torsion creates stress on a vertical plane, shear is a force that imparts a similar effect, but on a horizontal plane. It happens when environmental forces put pressure in opposite directions on a single fastened part of a bridge.

Vibration/ resonance — When wind or movement across a bridge matches its natural frequency of vibration, it can cause a phenomenon called resonance. If vibrations are extreme enough, they can disrupt crossings and cause a collapse.

The interplay of these forces looks like this: Gravity pulls down on a bridge’s structure. Forces of compression push the load inward onto piers at the middle of the bridge. The force of tension pulls the load outward onto abutments at both ends of the bridge.

When these forces act in opposite directions on a part of the bridge, it can create damage from shear. Wind and heavy loads can create torsion or vibration/resonance on a bridge, both of which also can be dangerous. Modern bridges are engineered to counteract these potentially threatening conditions.

Conclusion

Bridges, like buildings, serve us practically and aesthetically. They’re not just ways to get from one place to another; they also serve as landmarks. More than that, they’ve also become geographical and architectural symbols that help define us as humans, culturally and historically.

So the next time you approach a bridge, take a closer look. There are few places you’ll see art and science merged so seamlessly into functionality as in a bridge.

RAEM1 acoustic emission monitoring system can accurately detect the break signal of the suspension cable, process and analyze the signal, and then upload the signal to Qingcheng Cloud platform through 4G communication, so that customers can see the status of the suspension cable in real time on the terminal equipment. The built-in algorithm of the cloud platform software can calculate the wire breaking rate of the suspension cable through the received cable breaking signals, and can trigger an alarm when the wire breaking rate reaches a preset value, and notify customers by sending SMS or email.

RAEM1 Acoustic emission monitoring system composition

Bridge acoustic emission sensor: it is installed on the suspension cable of the bridge to collect the fracture signal, convert the signal into telecommunication and transmit the signal to the RAEM1 monitor after amplification.

RAEM1 monitor: Analyze signals from sensors and upload data to the cloud platform.

Qingcheng Cloud platform: real-time display of monitoring data, and provide calculation and alarm functions.

Results

RAEM1 acoustic emission monitoring system can dynamically monitor the phenomenon of broken wire of bridge suspension. Once broken wire occurs, it can realize immediate alarm and push the alarm information to the user's mobile phone. And it can work with high accuracy, no error or missing report, it can analyze the location of broken wire, time of broken wire, broken wire number and broken wire rate.