Rarer than the atomic bomb, only 2 countries in the world mastered, the manufacture of photolithography is too difficult

China, as the world's second largest economy, is leading the development of technology in many high-precision fields, but there is a symbol of industrial power of science and technology products, China has never been able to complete self-production, which is the EUV lithography machine.

The gold content of photolithography machine

At present, there are only two countries in the world that can manufacture EUV lithography machines, the Netherlands and Japan. Although the United States also does not have the manufacturing technology of lithography, but considering the alliance between the Netherlands and Japan and the United States, Britain and France are European powers in the Western camp, in fact, only China and Russia are excluded from the EUV lithography club.

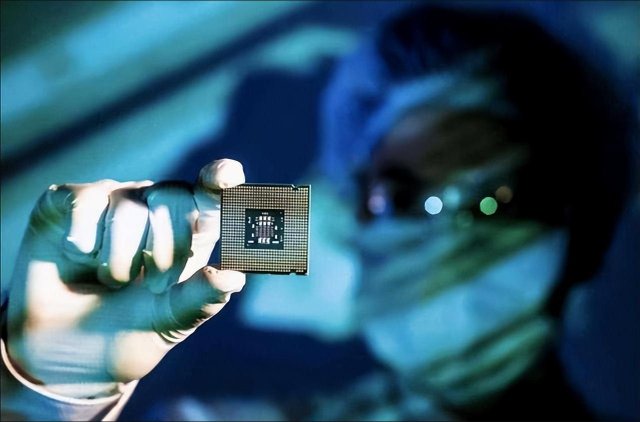

To understand why photolithography manufacturing is so difficult, first of all, we must be clear what photolithography is a thing. We all know that the operation of electronic products depend on the chip, the chip is like the brain of electronic products, the more powerful the chip, the more powerful the function of electronic products.

As a highly integrated technology products, the chip can run astronomical number of transistors in a very small volume, in the ancient Chinese language, is the snail shell to do the dojo. And the photolithography machine is born to complete such a tiny but fine operation.

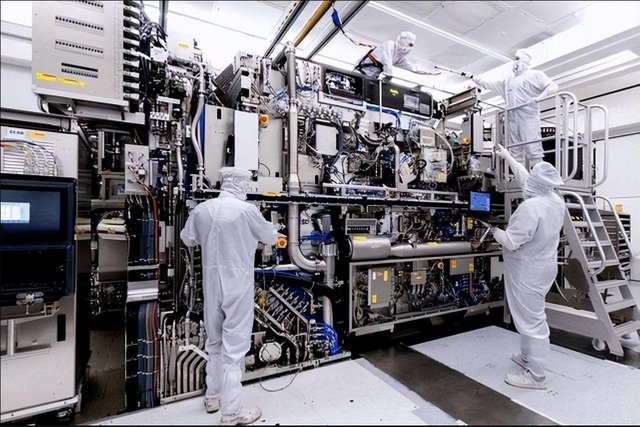

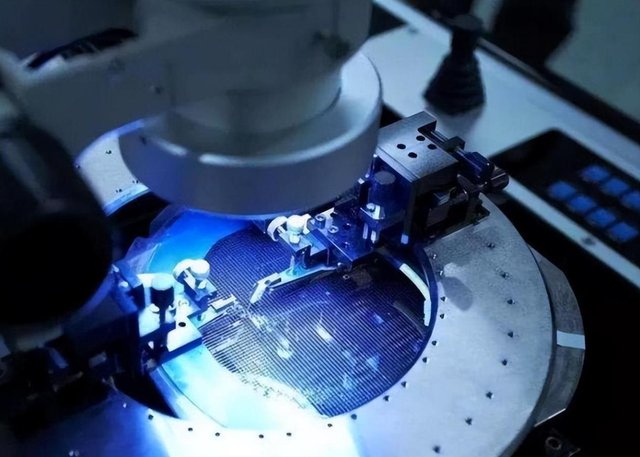

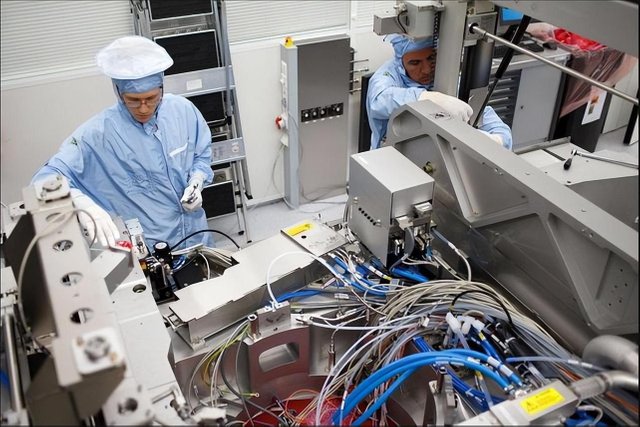

When the photolithography machine starts, it emits UV light to remove the protective film from the wafer surface, and then projects the circuit graphics onto the wafer with precision to create the graphic area that matches the chip's needs. Such an operation may seem simple, but nanometer-level precision processing is maintained throughout.

Especially after the iteration of lithography from DUV to EUV, the processing precision is more exaggerated, and it is more difficult than ascending to the sky for Chinese lithography manufacturing units to break through the technical barrier of precision. Even if we are fortunate enough to get the most advanced EUV lithography in kind, it is impossible to produce domestically because it cannot reach the same processing accuracy.

Japan and the Netherlands can become the world's only two countries that can independently develop lithography, largely because of the two countries' processing capabilities started very early. Through continuous iterative upgrading, in order to eventually lead the world. At present, the latest generation of photolithography machine has been able to process only one fifth of the diameter of human hair lines, the accuracy is amazing.

Technical Difficulties of Lithography

The first difficulty in the manufacture of advanced lithography is the light source of the machine, before the introduction of EUV lithography, DUV lithography is the mainstream of the world, the biggest difference between the two in with the DUV on the 193nm short-wave ultraviolet to 13.5nm extreme ultraviolet, lithography accuracy has made leaps and bounds.

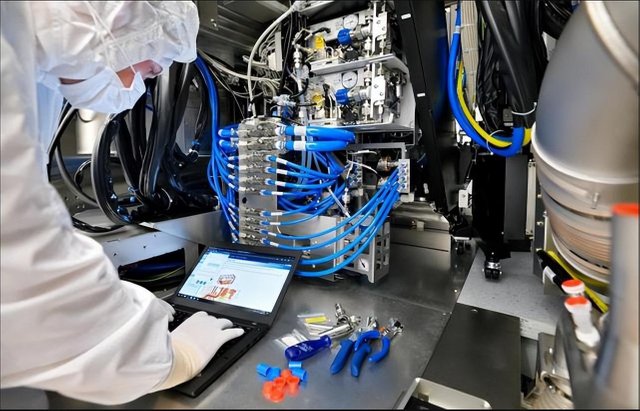

EUV lithography machine will use carbon dioxide laser to continuously bombard the DUV on the application of metal tin stock, so that it becomes plasma state under the laser, the wavelength is shorter compared to the previous. This technology not only tests the finishing ability of the machine, for the control of the laser emission software also puts forward daunting requirements, not to mention our country, only the Netherlands currently has a mature manufacturing technology, other developed countries will be purchased from its scheduled to improve the level of technology in their countries.

Reflector is also an important part of the EUV lithography machine, can meet the requirements of the lithography machine multilayer film reflector, only the old German lens manufacturer Zeiss can take out, this product is also installed in the ASML family's newly developed lithography machine, in order to achieve high efficiency of the EUV band.

In addition to the two key subsystems mentioned above, the table of the lithography machine also provides a very difficult challenge for the manufacturer. At present, the fixed operating table used in Hojic lithography machine, for such a precision machine, the table also needs to achieve extremely high precision, EUV lithography machine uses high precision laser interferometer in order to reduce the displacement interference of the lithography machine.

In general, the lithography machine represents the highest level of human mechanical processing, for a country's basic industry and precision processing technology is an extremely severe test. And this is precisely the lifeblood of countries with a short history of industrial development, and is the real reason why China is temporarily unable to build a truly advanced level of lithography.

Lithography or atomic bomb, who is more difficult?

When it comes to this, some people wonder why China could not develop a good photolithography machine when it had independently developed the atomic bomb in a period of poverty. In fact, the atomic bomb such a new technology to open up the equipment, the focus of research is to figure out the principle.

Our military workers also developed their own nuclear weapons only after understanding the specific principles of the atomic bomb explosion. But the photolithography is different, the principle of photolithography is known to all, but will be completely stuck by the process, in the end photolithography is a kind of leapfrogging progress on the existing technology to complete something, and the atomic bomb is very far from.

To make the domestic photolithography technology surging forward, the best way remains to feel through procurement and absorb the reception, but the camp represented by the United States has been stuck in our country's neck, not allowing our personnel to contact any technology related to photolithography.

This reality has prompted China to lag behind the continuous progress of upgrading the lithography industry, by the Netherlands and Japan to exceed many, and never find a way to crack. Relying on the monopoly of photolithography technology, the United States and the Western world blocked China to death in the sequence of advanced chip countries outside.

From this point of view, the internal and external difficulties faced by China in the development of photolithography are more severe than the manufacture of the atomic bomb at that time, and the difficulty of manufacturing photolithography is greater than the atomic bomb. From the current situation, it is still a long way off for China to make up for the lack of this field.

Our current progress

China's talent and efforts in this field are recognized by the world, and the director of the Netherlands Institute of High Technology has publicly stated that if not for the U.S. neck, China would be able to catch up with the world's advanced level in the category of 5nm lithography within ten years.

But reality is reality after all, China's 28nm DUV lithography is still not available, and the world's advanced level is still a generation away. Although the technical threshold of the DUV breakthrough can also benefit the domestic EUV, but when the domestic EUV mature, other countries may have completed another iteration of the development.

Although the future is still unclear, but the creation of numerous industrial miracles in China is still worth looking forward to, domestic lithography and domestic chips will eventually come.