CIBUS — USE CASE, CHOCOLATE BAR

A TRUSTED FOOD & DIETARY SUPPLEMENTS ECOSYSTEM ON BLOCKCHAIN -EMPOWERING CONSUMERS WITH TRANSPARENCY, SAFETY AND TRACEABILITY AT LOWER COST

CIBUS USE CASE — CHOCOLATE BAR

OBJECTIVE:

Trust on food is the most demanding aspect of customers that has increased in recent years. Quality and labelling information in food currently available, is just not enough to improve the customer’s trust. So it has become customary and necessary to comply with the mandatory declaration imposed by safety regulators and providing customer proper information about a food’s life cycle in order to achieve the complete food safety and thereby the consumer’s trust.

Objective of this use case is to establish how CIBUS is contributing to processed food business:

- To establish traceability covering entire ecosystem of sourcing, processing, storing and distributing.

- Enabling manufacturers to come forward to declare crucial traceability information and helping building trust among consumers on their brand

- To ensure quality covering all aspects like safety, organoleptic and texture in products traded on CIBUS platform.

CHOCOLATE:

The Aztecs and Mayans believed that their cocoa drink had a positive health benefit and there have been many documented uses of cocoa as a medicine over the centuries. Recently there has been renewed scientific interest into the benefits of eating cocoa and chocolate, particularly in the respect of reducing the risk of cardiovascular disease. Antioxidants in food are known to protect the body against chemicals called free radicals that damage cells. Cocoa is a known source of antioxidants. Chocolate is good for its catechins content from the family of flavonoids, which are among the most powerful antioxidants.

Since then a lot of work has been carried out, which has shown the beneficial effects of cocoa with respect to heart disease and possibly some cancers.

It is important to have a balanced amount of the different nutrients, which means having a varied diet. Although eaten mainly as a snack or treat, confectionery (including nougatine bars) provides about 14% of the energy of the average diet.

QUALITY:

Quality of chocolate product includes multifaceted parameters. It not only includes quality performance of raw materials and finished product but also good, aesthetic and informative packaging condition of the bar. Good quality chocolate bar will not only be safe for consumption from microbiological, chemical and physical safety point of view but will give consumers ecstatic experience like smooth melting inside mouth accompanied by desirable chewiness of nougatine. Guarantee of good quality chocolate bar is not only limited to the conditions met inside processing factory but sourcing of good quality cocoa, producing good quality cocoa butter, developing appropriate recipe and storing finished product in recommended temp. And humidity condition.

QUALITY AFFECTING FOOD SAFETY:

For any food article food safety is of paramount importance. This is especially important for bar chocolate because chocolate is widely consumed by children who are less strong in immunity. Moreover making process of chocolate does not require high heat treatment which will render it safe from microorganism. However water activity of chocolate which is around 0.6 is considered relatively safe. But ingredients such as milk powder, cocoa, whey powder etc. can add to its woos. Especially cocoa mass and powder which is mainly processed at semi-automatic condition can bring in microbiological

contamination like salmonella. Further processing of chocolate doesn’t involve enough heat treatment to sanitize it. Also chocolate plants are not cleaned everyday but once in 7–10 days, if any contamination originates at any corner of the processing line it will only propagate. Sometimes high fat content of chocolate gives protection to microorganism cells. To safeguard product it requires positive release of all micro sensitive ingredients like milk solids, cocoa products. Strict controls over critical control points of the processing line and also general hygienic condition of the plant and personnel. For machine maintenance NSF H1 grade lubricant needs to be used specifically on process equipment’s where product is handled.

QUALITY AFFECTING TEXTURE AROMA:

During the confection of the chocolate conching, tempering as well as the addition of ingredients such as sugar, milk and fats exert a powerful influence over the flow properties and final flavour of the chocolate. Other essential elements include the packaging, storage, transport and refrigeration of the finished chocolate product. There are thus a myriad of variables that have to be controlled throughout the entire production chain in order to obtain the best quality chocolate from the raw materials right up to the final product. Ultimate experience of consuming chocolate lies in its ability to smooth melting inside mouth. This depends on storage of liquid chocolate and tempering of chocolate before enrobing. Chocolate temp. Shouldn’t increase 450C. Stored chocolate should continuously be stirred to check viscosity increase. Viscosity should be kept at max. 150 Sec. by adding cocoa butter. Tempering is important to give gloss and melting property. Maintaining temp. In cycle of 280C to 310C in temper is required to produce good quality chocolate bar. During preparation of sugar syrup and caramel proper filtration is needed to avoid lump formation. Maintaining predefined temp. For caramel and nougats making is very imp. To attain proper texture.

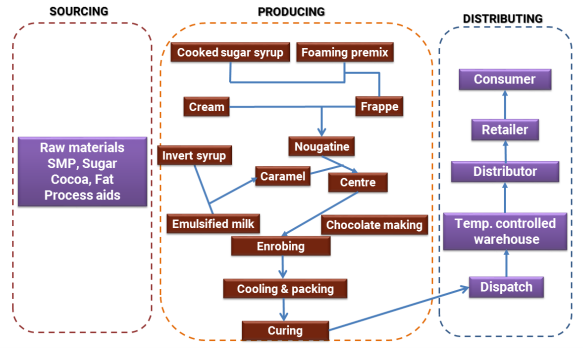

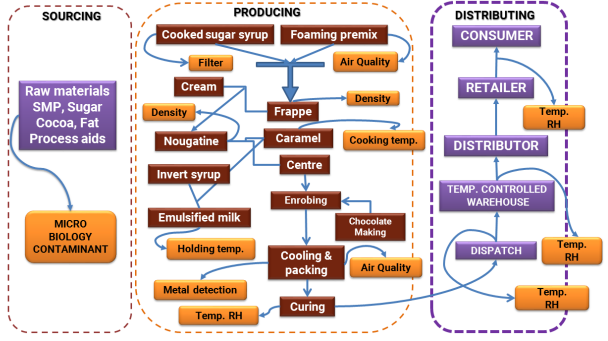

Process diagram of chocolate bar manufacturing

Supply chain ecosystem of chocolate bar:

Control over quality starts from sourcing of raw ingredients. Milk powder, cocoa products are to be safe from bacteriological point of view. Once all quality parameters are satisfied then these and all other ingredients are taken into production. Presence of pesticide residue, dioxin, PCB, PAH, foreign matter can be a matter of concern for its quality. Availability of test reports of critical parameters is of paramount importance.

During frappe making beating speed of beater to be controlled so that foam structure is not collapsed which is critical for product consistency. Density of frappe and nougatine is very important parameter to check here to have desired texture. These bar products are known for their texture and chocolaty taste.

In emulsified milk preparation stage it becomes very important to hold milk solution above 550C. Otherwise growth of staphylococcus aureus will reach over 1 million and leave toxin trail. At this stage it is very important to have a record of emulsified milk holding temp. In caramel preparation recording min. temp. In cooker is critical from microbiological safety point of view. If right temp. Is not given for adequate time then contamination of Listeria may persist. In many places in processing in sugar syrup making or caramel syrup making filtering is done to keep away any foreign material. Condition and

sieve sizes are therefore very important to watch out for. In most production plants metal detectors are based at before final packaging. Performance of metal detector is a very critical parameter to keep in control. Compressed air is directly mixed with product at some places like transporting sugar, in making foam. Hence filtering air before use is one critical aspect to prevent carryover of oil.

Storage of finished saleable goods at right temp. Is crucial for enhancing its melting experience. During storage at 230C product gets cured. Cocoa butter particle crystallizes which gives gloss and smooth melting in body temp. Inside mouth. Also any variation of temp.

At this stage or later stages like transportation to market or at store will result in melting of fat and skimming on top surface giving defects like fat bloom. So, in whole supply chain of chocolate bar maintaining right temp. Profile is important for a getting a good product.

Critical quality parameters to ensure good and safe product

HOW CIBUS IS BRINGING THE CHANGE:

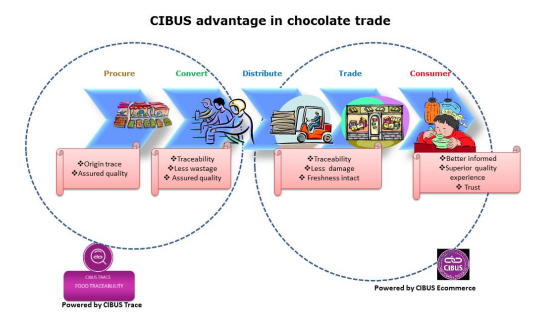

CIBUS encourages manufacturers and suppliers to put more and more traceability information on its platform to invoke trust on their products among consumers. CIBUS extends support to its partners to identify critical to quality (CTQ) parameters associated with sourcing, processing and distributing.

Widely used practice across industry is to maintain manually recorded documents or using various software modules. These are not properly kept and lack tight measures to prevent counterfeit. One more limitation of this system is that it doesn’t follow the product once it has left the factory or doesn’t keep record beyond lot no. and COA of its ingredients. Here CIBUS provides a secure platform in the form of blockchain shared ledger where data once entered can’t be altered and be visible to willing partner irrespective of their geographical spread.

CIBUS Trace process will start from implementing traceability in Input which will involve large no. of stakeholders and managing data from them .Then traceability will be implemented in the production house where all components of chocolate bar will be produced and finally put together to make the final product. Lastly traceability system will follow trajectory of final

product through warehouses, trucks and distributors place. Critical information about each raw ingredients like microbiological test report of sensitive products who’s aW is more than 0.6 will be entered in the platform.

For agricultural ingredients especially for sugar, cocoa etc. environmental contaminants like PCB, dioxin, PAH, pesticide residues etc. information will be captured. These will ensure safe and quality input for process.

During processing temp. And holding time for thermal critical processes like caramel cooking, premix cooking, emulsified milk preparation will be captured through sensors placed in the respective equipment’s. Density of center like frappe and nougatine will be entered in the system basis on-site laboratory test result. At the end before final packing all products passes through metal detector. Test reports of metal detector of every batch will be available through CIBUS module.

Ensuring quality of product is not only limited to testing product and process records but to check atmospheric components like air and water which often comes in contact with product. At some places like in beater and agitation compressed air is used. Compressed air needs to be checked for oil carryover. Water is used in making sugar syrup, caramel, emulsified milk preparation. Water test reports for bacteria, virus and protozoa needs to be entered in the system to ensure that no incidental contact is capable of introducing any unsafe element.

Daily test report of water and periodical report of air quality for both pressurized and non-pressurized air will be available in CIBUS blockchain platform. Such reports will build confidence about manufacturer’s capability of maintaining plant condition consistently. Basis this consistency CIBUS will rate manufacturers which will be available in UI of CIBUS.

Benefits of partners in food trade using CIBUS platform:

Consumers can ask for traceability information for product they wish to know .Our platform will present that scope for knowing your foods better. It will create opportunity for all stakeholders to connect with each other through CIBUS platform. Consumers can ask for traceability information for chosen parameter or for entire process and that will give manufacturer an insight about their product and customer preference for any particular trait of their product.

This will set transparency in food trade. CIBUS will encourage manufacturer to come up with more information of their product and creating trust about the fact that their product is safe. Similarly CIBUS will encourage consumers to know more about what they are buying. Understanding what parameters are crucial for quality and safety and keeping a track on those will help prevent huge loss in case of any recall situation. Timely action will save both money and confidence of consumers.

Moreover CIBUS blockchain provenance will ensure that data saved in blockchain is authentic and verified by CIBUS experts and unalterable. By giving an opportunity to consumers to know from where their chocolate bar is coming and how this is manufactured CIBUS is promoting popularity of good affordable foods and empowering consumers to choose best from the rest. Consumers and any other stakeholders will have access to these information through CIBUS apps or website with user-friendly interface like QR codes. Our database will prove to be boon for manufacturers. Their best practices followed in manufacturing processes will be showcased and that will make difference for their brand.

MORE INFORMATION ABOUT CIBUS VISITE lINK:

CIBUS DOCUMENTS: https://www.cibus.world/documents/

ANN BITCOINTALK ABOUT CIBUS: https://bitcointalk.org/index.php?action=profile;u=1297756

MY PROFILE: https://bitcointalk.org/index.php?action=profile;u=1761658