BELT AND BELT DRIVES; UNDERSTANDING THE TRANSMISSION OF POWER ON ENGINES

We all talk about engines and how they move and rotate converting one form of energy to another. Just like the crank shaft converts linear motion to rotational motion of the flywheel. But have you ever wondered or asked how this rotational motion is transmitted to other engine parts for kinetic motion of your vehicle? or how your alternator moves relatively with your engine movement?

BELT

Well according to a Wikipedia belts are known to be a piece of clothing or flexible material usually worn round a piece of clothing (trouser).

Of course, we are not talking about belt used for clothing’s although they are both black and rugged but they do different things. We are talking about the mechanical belts used in engines. Wikipedia defines this belt as a loop made of flexible transmission that can link two or more rotating shafts together for the sole puropose of power transmission.

I am very sure most of us see this black thick thing that rotates along with your engine either in your vehicle bonnet or generator engine (if you run an alternator engine). Especially in the Nigerian homes some of us have been whipped with this strong black thing which is very strong and painful.

I know you have an idea of what this thig does as when it slips or falls away the other part stops working. Therefore, this endless circular black substance is called a belt and you are right basically to a layman the belt transmit motion in form of power from one part of the engine to another. Belts are usually placed on pulleys which are wheels on a shaft or axle.

THE MATERIAL COMPOSITION OF BELT DRIVES

The materials used in making mechanical belts should have certain characteristics some of which are flexibility, durability, and reliability. Therefore, certain materials which have these qualities are leather, cotton, rubber and plastic. The application of these belts determine what material type of belt should be used.

TYPES OF BELTS

There are several types of belts used for several purpose and application in the engineering world. Some of which include;

- Flat belts

- V-belts

- Flat belts

- Multi grooved belts

- Ribbed belts

FLAT BELTS

Flat belts are usually designed for light transmission of power. They are one o the earliest forms of belts and are used for small pulley with a large central distance. They have high transmission efficiency, cost effective and usually easy to install.

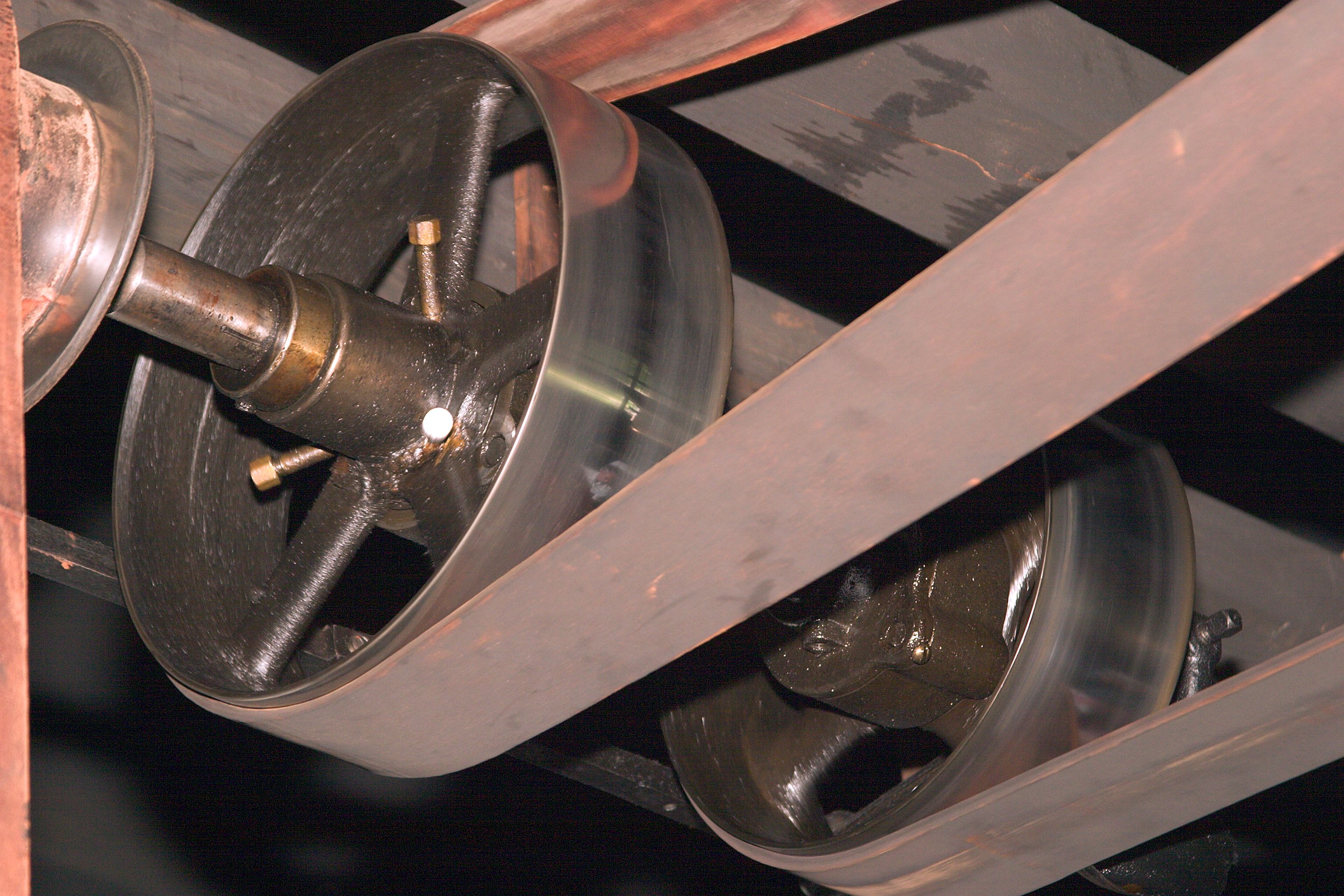

flat belt from Wikimedia under CCO license

V-BELTS

This type of belts is usually triangular or trapezoidal in shape used for transmission of power. They are used where speed ratio is not critical. They are used for very high-speed transmission of power.

MULTI GROOVED BELTS

A multi groove belt usually consists of several v-belts joined together. It is much more flexible and wider which results inn more efficiency and more power transmission that the v-belts.

RIBBED BELTS

These belt types operate by contact between the rib of the belt and the grooves of the pulley. They are used for even distribution across pulley width where belt is in contact. They are used where there is high speed ratio such as in washing machines, lawn mowers.

BELT DRIVES

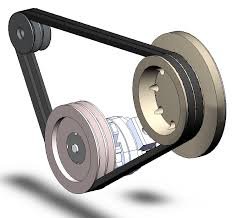

We have talked severally about belts now, but belts don’t move themselves as they are mounted on something called pulley once mounted on a pulley it results in what is known as a belt drive as they are responsible for how the belts move the speed and the power at which the belt transmits. There is a driver pulley and a driven pulley the pulley that owns or causes the motion is called the driver pulley while the driven pulley lacks motion, or it is the stationary pulley that you need power in.

belt drive from Wikipedia under CCO license

TYPES OF BELT DRIVES

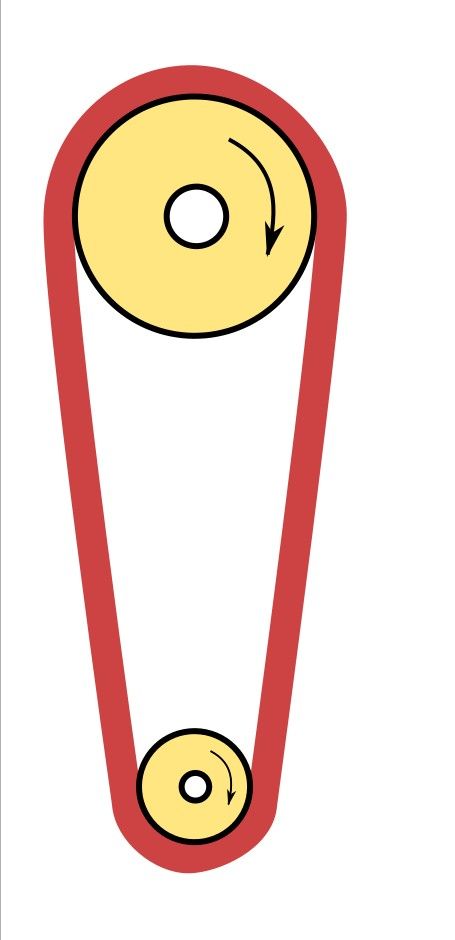

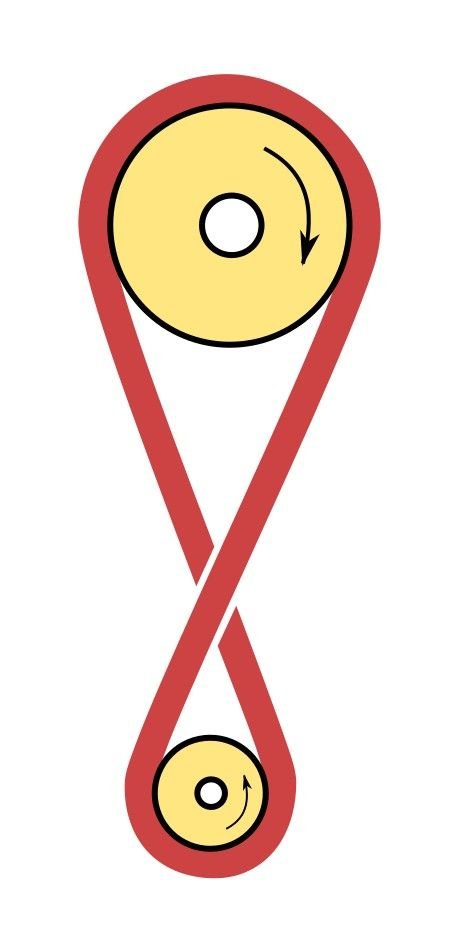

There are two types of belt drives which depend on how the belt operate or behave which are the open and the crossed belt drives.

OPEN BELT DRIVES

Open belt drives are used to rotate the driven pulley in the same direction as the driver pulley. When motion across this belt drive occurs, one side of the pulley is more tightened compared to the other.

open belt drive from Wikimedia under CCO license

CROSSED BELT DRIVES

Crossed belt drives rotate the driven pulley in opposite direction to the driving pulley. The wrap around this kind of drive must be great for more power to be transmitted when compared to open belt drives.

cross belt drive from Wikimedia under CCO license

APPLICATION OF BELTS

Belt drives are used in several devices and equipment’s where noise is not needed, and friction needs to be overcome some of these applications are In conveyor belts, escalators, mowers, vehicles, generators and anywhere power is needed to be transferred.

ADVANTAGES OF BELT DRIVES

- Belt drives simply saves you enough money as they are economical.

- Belt drives do not require parallel shafts.

- Most belt drives are provided with overload and jam protection.

- Reduced noise or noiseless operation are one of the best characteristics of belt drives as they increase machine life.

- They require little or no maintenance operation as they do not need lubrication.

- They have high efficiency.

DISADVANTAGES OF BELT DRIVES

- The velocity ratio of belt drives is not equal or constant due to slippage or stretching of belts

- Heat occurs as we all know friction acts against movement which causes heat.

- Operations are usually restricted to certain temperatures due to the material.

- Adjustments of center distance are done for comprehension of the stretching and belt wearing.

CONCLUSION

The importance of belt drives is felt in many engineering equipment’s as transmission of power is essential in mechanical engineering. Belts are endless and usually of low maintenance with little or no operation or lubrication. Belts are made up of several materials whose application depends on the selections. Belts are usually mounted on pulleys and are called drives which may be open or closed. The importance of belt is very essential as without these your equipment or tool might just have a part working with the other useless there by costing you more to move all parts together.

In the event of all that has happened in the steemSTEM community, as an engineer I belong to them I say we all come out to support and stand by them and engage in the comment and on discord. Help your fellow scientists, engineers technologist and mathematicians. Build a connection and make friends most of all don’t forget to have fun.

REFERENCES

For further reading please use any of these books or read the links.

- the-material-used-in-belt-drive

- Belt

- v_belts

- belt-drives

- belt-and-chain-drives

- a text book on machine design by R.S Khumi.

- flat_belts

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details. You can also check this blog post by @steemstem here and this guidelines here for help on how to be a member of @steemstem. Please also check this blog post from @steemstem on proper use of images devoid of copyright issues here.

This post reminds me of my O level physics, the pulley systems, mechanical advantage, velocity ratio, work done, efficiency. surely, all these are considered in fabricating mechanical belts

Yes sir, I am glad to have brought back memories. It partially physics and something we did machine design at undergraduate level. So much factors are involved in the design.

Belts are key in Vehicle operation...had similar experience as @greenrun with the timing belt..The car then just suddenly stopped working in an hold up..rolled the engine over and over but all was in vain until i called up a mechanic to reset the timing belt as the vehicle has jumped timing which took almost like 3hrs under a very hot weather to rectify...then i had my first experience with Timing belts

All vehicle parts plays a very important role for this Kinetic energy to be achieved

Thanks for sharing this @adetola

We all hate when that happens. I wish mine was in the day.

Omg!.. Seems like everyone has once had an issue at least once with belts. It is very bad experience from what i have read here. This is one of the disadvantage of belt drives i hope some thing better than the belt and chain drive needs to be developed.

Belts are essential machine elements in machines that require power transmission. I know certainly of that in car engines. Belts are used in automobile engine to transmit motion from the crankshaft to important components, like, power steering pump, compressor, alternator, etc. Also some valve timing systems like in Acura cars use belt to connect the crankshaft to the camshafts.

Yes sir, although I am not so familiar with the automobile engine but its a bit similar to the generator engine and this pepper grinding machine this was where we used it then was from the flywheel to the other part used for grinding. Several people used them in their projects also maize sheller and the likes. Thanks for reading.

Your type of belts isn't complete oh, you didn't include the one my dad uses to flog me when I sneak out to watch Arsenal lose to stoke city. ☺ ☺

How do we know the length of belt required to transmit a particular power?

Lol. I actually mentioned it. The clothing belt you mean. Well some have been flogged with the fan belt am sure they will tell you you are very lucky to have been bitten by that type of belt.

Well several factors are used to calculate the belt length pulley distance is one for sure i can remember right now also the length of belt calculations are for both types of drives the crossed and the open. I was thinking of adding the formula breakdown but i can't get hold of how to make those formulas sit here comfortably. Very soon sir. Thanks for reading.

You could write equation with Microsoft word and screenshot it, then you crop into a thin line of equation.

Well that would take a lot of time if you consider the fact that am not always with my system. Not like i can't do it but i like my post to be very easy to read and understand. I will find a way round it.

Alrighty

The day belt dealt with me was in the middle of nowhere at night. Suddenly the engine died in the middle of the road. That was an express road, we tried to start the car and nothing happens. We were unaware that the timing belt decided it was time to cut. Luckily, we got a mechanic, we all donated our phones as torchlight for him to work on. I have no idea you have to remove so many things to get to it. It took him 6 hours to get it all fixed, by then it was almost 1AM..We left for home and arrived without incidence.

The belt was a notched rubber type of belt (similar to the first image in this article) . It requires a special way of changing since if done incorrectly, the car won't start. I learnt a lot in that 6 hours... almost like a crash course in belts and pulleys in the middle of nowhere at night!

Chai.. Well the car engine are compact depending on the manufacturer and model of the car. But it is easier to reach in some other engines. I hope mechanic didn't make a months salary off you?

Belts are not so easy to fix you have to get to the adjuster first and feel the tension of the belt. Too tight a belt could damage the belt as soon as its fixed and if its too slack its another problem as it could slip off again. If it was the first image that is a flat belt sir. Its a common type of belt.

Am glad you found a mechanic that night. I remember my dads car had a similar fault it was stationery couldn't remember how he got it fixed as we all left him with the vehicle to go home.

Thank you for reading and taking time to comment.

Belts are super cool and could sometimes be super annoying. Like one time when the timing belt of my vehicle cut and days were spent trying to get the exact fit.

Yeah.. Its a bit better than chain drives but it is difficult to set as most roadside mechanics only use their hands to feel for the tension. Quite sad but they would be off the market soon enough.