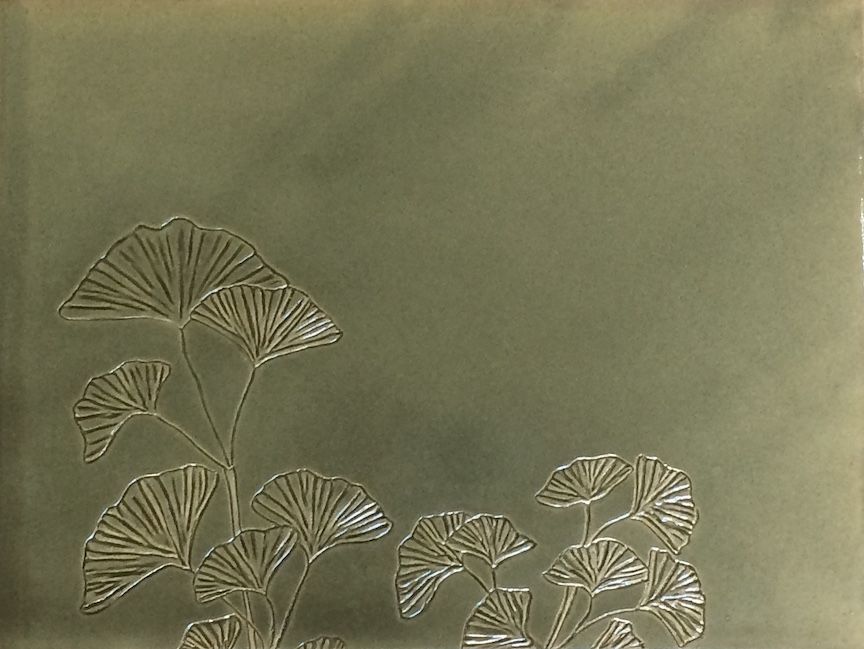

Gingko Tiles Bisqued, Glazed, Fired!

My Gingko Commission is Ready for Installation

Yesterday's post gave an overview of this Gingko Tile commission, showed my process of preparing the Gingko tiles for firing, and a bit about the firing process.

After 40 hours of candling, firing and slow cooling, it was time to open the kiln.

I could hardly breathe as I unloaded the kiln and with each shelf felt a little more relief as I saw that there was no cracking, no warping, no problems. Whew, phew, I danced a mini jig. This large a tile (15" x 11") is prone to all kinds of issues and there were so many hours of making in each one that some part of me was held in suspension until I saw the results.

This first firing is what's called a "bisque fire" and it heats the clay just hot enough to alter its composition so that the clay can't decompose back into its original state even if left in water for years. Clay that has made it through the bisque fire is much stronger and can sustain a lot more vigorous sanding and handling as needed.

First I examined each and lay them out altogether to make sure all 5 fit well. The first of the two stage glazing process was to hand glaze all of the gingko leaves and branches with a slightly richer glaze so that they will standout in the face of the very similar field glaze:

And all 5 tiles after hand-painting:

Next, I made a tub of the field glaze where I dipped the front of each tile. I had to strategically plan how to move each tile around after it was dipped so allow the glaze to run off for a favorable effect. My goal was a somewhat even field of glaze with some areas of variation. I know this glaze well and it can look olive green or have blue undertones depending on thickness of application and I wanted some of both. There are floating gold flecks in this glaze which are extraordinarily beautiful but unfortunately I haven't yet been able to capture them in a photo.

Then they went in the kiln again for the "glaze fire". Below are the fired tiles, a detail and the whole group of 5. I was pleased that the blue undertones came through in the darker areas and just enough variation to give the piece some mood. I especially like the top 2 tiles.

For optimal lighting and less glare, I took these outside to the driveway to photograph them:

Once these are installed, I'll be sure to post photos of the client's completed master bathroom. Thanks for following the process of this project, I enjoyed sharing it! And as always I am grateful for your support of my blog.

You got very definite motion and tone with the field glaze. It's interesting how it settles in the lines to define them more clearly. The finished work is gorgeous. I'm quite positive that it will add beauty and value to the area where it's finally placed. What a process, wow! The client got a deal.

To tell you the truth, initially I wanted to reglaze and fire to minimize the lightness at the edges, but the client and I weighed the risks against the possible gains and decided against it. I agree with you that the tonal variation does offer some nice motion and moves the eye around the piece. Thanks for your comment and support, I appreciate it!

Nice

thanks @milfa :-)

Wow! I just started to work on a new flat and those Tiles would have looked great on the bathroom. I am really curious to see a master bathroom as you promised to show us! Following you !

thanks, I can always make you some, I accept SBD ;-). Thanks for checking out my blog.

Hey nature, great job on the tiles! Looks great. I bet it's expensive to buy custom tile like that. Very interesting.

thanks so much @cyberblock. "expensive" is one of those funny words that is relative. Compared to what is the question! We have expectations of how much a cup or a car or a banana will cost and these days we are used to prices from products made in other countries and often of vastly inferior quality and at the expense of the environment and the quality of life of the employees. So, the feelings we have about price are arbitrary. All of this is to say that my tile is not expensive if one considers what goes into it, the exceptional quality and such, and what this many hours of work and level of mastery would cost in another industry. However, $900. can feel like a lot of money to come up with for almost anything so maybe it's expensive?? Long answer to a simple comment.

Gorgeous tiles, I imagine your client is going to love the final result. Looking forward to seeing more photos!

thanks @runaway-psyche, he is super happy which is always great!

These are so elegant!!! Was your customer pleased? These tiles are beautiful and very organic.

Thank you so much @rebeccaryan :-))

Yes he is very very pleased!!

Just lovely.

thanks @agbaba!

Congratulations with the outcome of such a difficult process. I love the glaze. Did you develop it yourself? I mostly throw my ware, but occasionally I try something flat and find warping a real issue especially when glazing at cone 8.

So great to learn of another clay person here (I only know a few including Simon Leach)! I love this glaze too and I can't take credit for formulating it, but I have tweaked it and learned how to apply and fire it in alternative ways to give me the results I want. It's a glaze by Mayco called Smokey Agate but it was discontinued about 4 years ago and I bought out all of the sources I could find at the time. Warpage is especially an issue with high temperature clays! I've found that a lot of grog and sand especially of varying meshes makes a lot of difference.

I am still trying to connect with potters on steemit, but I find it difficult. My last post had 3 views, so that is not the way to reach them either. Anyway, quoting Simon 'we keep trying' .

The finished product is a masterpiece. It's amazing to see the process with how they turned out to be the artwork they became. I like the darker tones. Makes it more dramatic :)

thanks @unspeakableme, I like those darker tones with the blue undertones too

Looks really great! And no casualties in the kiln.

thankfully no, whew! Thanks @ocrdu...I'm a fan of your posts btw ;-)