A chair, worthy of the name?

Hello my Steemian friends.

A few months ago I was commissioned by a local restaurant to design and make a set of dining chairs. The only design guidance offered was to make them comfortable, but not so comfortable that people would not want to leave. At first this confused me, not being in the restaurant business, but it was explained that it’s all about ‘covers’ i.e. the number of sittings per night with the optimum being as many as possible and a really comfortable chair would provoke a longer sitting therefore fewer covers per night.

So with this and no other information in mind I set to work.

I have always been a fan of wrought iron combined with wood as a style in furniture so decided this was the direction I would take. From my earlier posts you will know about my steel bending machine and I put this beast to good use during the first few days of the project.

Having no idea about CAD (Computer Aided Design)and being a bit inept with a pencil, the first stage for me is always to just let my creativity flow into a fully functioning and full size prototype. This project was only the second in which I was to use the bending machine and I had only used it to bend ½” steel so that is what I chose to use for the basic structure of the chair. I measured, cut then bent the various components then came up against the first of many challenges in this project.

Most of the components were irregularly shaped and this presented me with some difficulty when it came to welding them together. On the equipment side I posses a number of ‘G’ clamps, two long pipe clamps and a couple of welders vice grips. When dealing with regular, straight or square components it’s a simple task to clamp them together then tack weld the pieces to check alignment before final weld. On this occasion I found myself adopting some pretty contortionist style body positions in order to hold the pieces together for welding. Not having photo’s of these, I’ll leave it to your imagination.

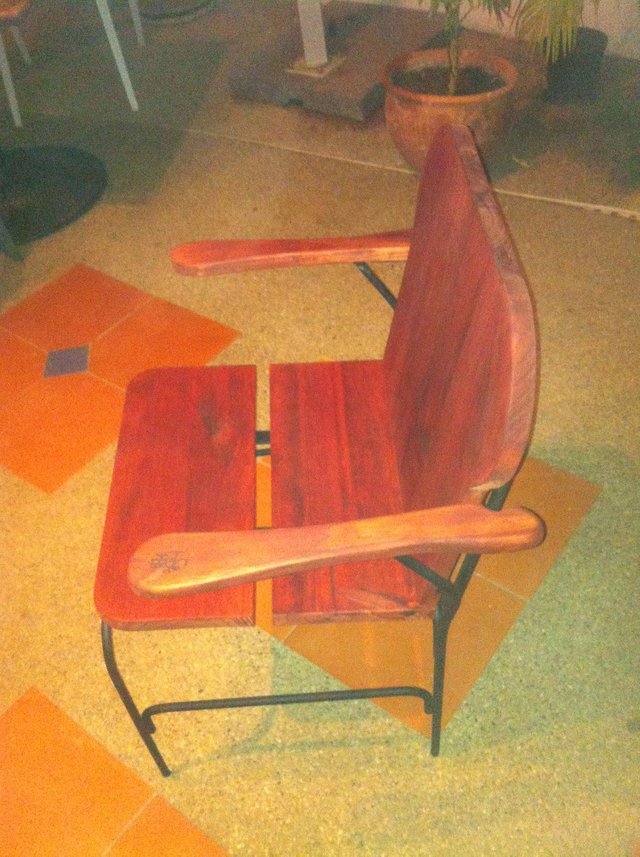

After about a week of work I produced this:-

I called up my clients and arranged to show it to them at their restaurant. As many of you will understand I was nervous and unsure as to how my work would be received as I climbed the steps up to the restaurant terrace. The two gentlemen owners were there to greet me and while the one was over the moon at seeing my work, the other remained quiet. I enjoyed the praise from the happy partner but was concerned by the silence of the other so asked his opinion. He hated it.

I was somewhat stung by his comments but took them in my stride and remembered that this was more of a development meeting than a final presentation. Taking emotion out of the equation and listening to what he actually said gave me all the information I needed to go back and re-work the project.

The first change was to up-size the steel used for the basic structure from ½” to 5/8”. This was to be a real test of my bending machine as I had no idea if it was capable of bending steel of this thickness cleanly.

Though it required considerably more physical effort, the bends came out smooth and I had to admit that the thicker steel did look much better. I cut and bent the components then, having the experience of making the prototype behind me, it was a much simpler task to tack then weld the pieces together and the production of the second prototype was ready in just a few days.

With trepidation I took it over to show my clients. It was a home run and it took only a few minutes scrutiny before they placed an order for eight. Once the first eight had been delivered further orders would follow up to a total of fifty. I was ecstatic and couldn’t wait to get started.

Having noted all the dimensions of the components it was a simple task to cut and bend all the pieces so in no time at all I was ready for final weld.

The feet took a little time but the trickiest part was welding the structure which supports the arms. Ensuring the exact position of the steel when there was no way I could find to ‘jig’ the piece meant a good deal of failed attempts on every chair and this certainly tried my patience. I persevered and, though it didn’t get easier with practice, all of the chair frames turned out perfectly so I lined them up ready for paint the next morning.

I awoke the next morning and opening my eyes it felt like I had rubbed sand in them. This was a new sensation to me and looking at myself in the mirror I saw that my eyes were badly bloodshot. I had heard about a condition suffered by welders called arc eye which occurs if one looks at the spark without using the protective eye wear. It’s basically a burnt eyeball and I’m told it’s excruciatingly painful. Although what I was feeling was uncomfortable, it wasn’t that bad and since I hadn’t looked at the spark without protection I didn’t think it was arc eye. After a quick internet search I realised that I had conjunctivitis, otherwise known as pink eye.

Having no choice but to keep working; I had deadlines to keep, I went to the local drug store and was able to procure some eye drops. The drops did nothing to alleviate the discomfort but I was told they would speed up my recovery. Putting on my sunglasses to provide at least some protection for my streaming, teary eyes I got to work painting the chairs’ steel frames and by the end of the day was well satisfied with the results.

The final stage of the process was to cut, stain and fit the wooden pieces then give the whole chair two coats of clear, polyurethane varnish. I opted for the variety used on cars as it is extremely durable and looks excellent to boot.

Here’s the final product. I’d love to know what you think :D

And what became of the first prototype?

I turned it into the exercise chair I used to train my arm for kite surfing.

And very comfortable those chairs , great job .

Good thing your eyes weren't worse after that.

Very nice work, you are very talented!

I may be talented but I am definitely forgetful. I have now corrected my error and added your wonderful Gif

Thanks again @papa-pepper

I totally did not even notice!

That's two of us for forgetful! LOL!

Thank you my friend :D

nice work , nice story @handsolo!

Thank you my friend :D