COB:Natural Building and bioclimatic architecture saving natural resources and energy

In cob.gr we deal with natural building and bioclimatic architecture, two practices that result in saving natural resources and energy, the first one at the construction stage of a house while the second one at maintaining stable conditions into it. Both of these practices result in huge enviromental but also economic benefits.

Natural Building as a term is quite new and is used to describe a building approach oriented at the use of natural, local, carefully chosen or recycled materials, simple tools and buiding techniques.

Almost in every place nature can provide us with the building materials we need. Because these materials do not need transportation, the economical and enviromental cost is very low. Some of these materials are renewable ( like the trees or straw) and some others ( like stones or earth) exist in such an abundance that are practically inexhaustible.

Contrary to industrial ecological materials, natural materials include none or minimum processing. The use of these materials does not contribute to forest destruction, waste of natural resources, pollution and doesn’ t depend on industrial materials or heavy machinery. Earth is non- toxic and totally recyclable. In these times of environmental degradation and lack of natural resources, alongside with the thousands of hidden toxins in our houses wouldn’t it be more reasonable to return to more innocent, cheap and healthy building materials?

We also deal with matters concerning energy, food, cultivation and generally with anything that can make our footprint more light and fair for planet earth.

Techniques:

Poured earth:

The poured earth building method is quite similar to building with concrete, because the materials are being mixed the same way using concrete as bonding material. The only difference is that instead of using sand and gravel as we normally do with concrete, we use common earth ( however this earth must have some specific properties). Apart from that less cement is being used.

For these walls no specific maintance is needed, since they are high resistant to the sun and the rain. The ideal earth must be of low percentage in clay. The appropriate tests must be done in order to ensure that the mix doesn’ t shrink or shrinks in a very small degree and can withstand compressive loads of 800- 1200 psi. The use of lime, pozzolan and magnesium oxides can reduce the percentage of cocrete used in the mix up until 50%.

Straw&clay:

The straw & clay technique is used to build walls that don’t bear loads. Straw, preferably long fibered, is mixed with clay that works as the bonding material.The straw is soaked in a solution of water and clay and is being compressed into molds of 0,50m maximum height. When the material is dry, we continue building further above.

The advantages of these technique are the high speed of construction and the exceptional thermal insulation. The disadvantages include the high cost of the construction because of the need of a structural frame for the building.

Rammed earth:

The rammed earth technique is at least as old as the Great Wall of China. In this technique loamy earth slightly moistured is compressed until it is absolutely solid, producing very flat and vertical surfaces. Usually heavy machinery is being used to move and compress the material.

The walls are at least 35 cm wide in order to be strong enough and to have satisfying thermal mass. Houses made with this method give a very solid sensation. Additionally, if more than one colours are used the result is very beautiful. This method draws back in comparison to other natural building techniques because of the need for heavy machinery in order to build, which is a factor that rises the cost. Unless you have a lot of Chinese available…

Waddle and daub:

In this technique a mix of clay and straw is being applied onto frames of plaited cane, wood etc forming thin and light masonry. It ‘s being widely used in interior walls, ceilings and generally wherever there is the need for light constuctions.

In this technique a mix of clay and straw is being applied onto frames of plaited cane, wood etc forming thin and light masonry. It ‘s being widely used in interior walls, ceilings and generally wherever there is the need for light constuctions.

Earthbags:

The earthbag building way is both new and old. Sandbags have been used by the army for fortification works or for controlling the streams of rivers. The same reasons that have established earthbags appropriate for the tasks mentioned, also apply for building houses. Really solid and stong walls are being created that can withstand all kinds of loads, from bad weather conditions to bullets and bombs.

Earthbags can be built really fast and with very few and basic tools.

This technique was introduced as a house building method by the architect Nader Khalili, who was experimenting using earthbags as structural elements, creating domes and arcs. Khalili was familiar with building techniques from the Middle- East where adobe bricks are used to create structural elements of this kind. His observation was that bags filled with earth are ideal for dome shaped houses. The bags are filled with slightly moistured loamy earth and are stacked one on top of the other in layers which are compressed really good to take the air out. At the beginning, hemp bags where used which functioned perfeclty until the bags rot. They were succeeded by polyprpopylene bags which, if kept out of solar light, have greater resistance. At permanent constructions the bags must be covered by plaster. And while Khalili died the earth bag technique continued evoluting.

Their most advanced form is called hyper adobe, where lattice bags, that come in 1 km rolls, are used. As a result, we have more solid constructions without the need to of in- between bonding elements, easier to build, with enhanced breathing abilities.

Cordwood:

We just build with logs as we would with bricks or stones, using mud as bonding material. The advantages are the quick building and the good looks. The disadvantages are, that in order for the wall to be strong it has to be very thick and that it can crack because of the movement and shrinking of the wood.

Lime- rags:

If we soak old clothes and fabrics into lime, place them on a light structural frame and let them dry, the result will be something similar to plasterboard. A very good way to built interior walls, special constructions ( like fireplaces) but also houses.

Strawbales:

Strawbale houses are quite trendy in England and the US while gaining more and more popularity in Greece. Straw as a building material is a renewable source, has great insulating abilities, better than any other material and is quite easy to build. The only thing that can count as a disadvantage is the specialized work needed at the construction of the structural frame of the building.

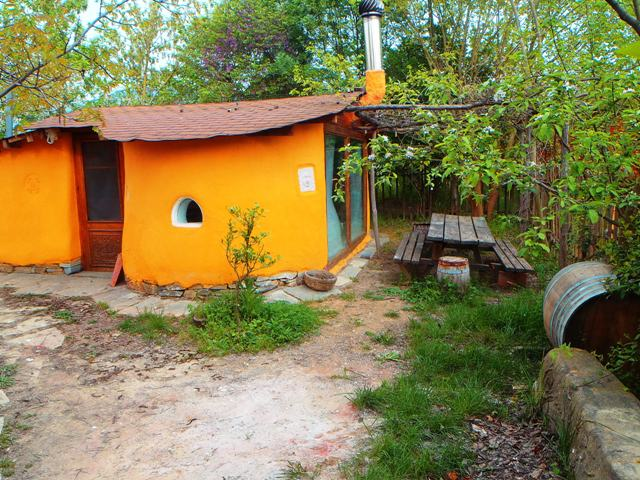

Cob:

Cob is one of the most ancient methods of building with natural materials. Legs and hands are used to form masses of clay mixed with sand and straw which then are being placed one on top of the other creating that way monolithic constructions of great stability. The word cob is an English one that means small ball.

Having a histroy of thousands of years, cob has been used until the middle of the last century in England, where one can find 500 years old houses built this way. Some of its advantages are the construction rigidity, the simplicity of the tools used and the great freedom of the design. Since no straight forms are demanded the material itself leads to organic shapes: curved walls, domes and arcs. Building with cob is an experience similar to clay sculpting. Disadvantages counted are the slow building procedure and the difficulty of construction. Cob houses are very resistant to a variety of weather conditions that makes them comfortable and viabile at the most cold climates but also in dessert conditions. Cob has been used for thousands of years even to the harsh climate conditons of the British coasts of the Aleoutian Islands. Thousands of comfortable and graphic cob houses at England have been habited continuously for centuries having great current market value. The rebirth of cob started in the US, where enjoys a continuously growing popularity not only because of the advantages already mentioned above but also, because of the ability provided to the owner- builder to avoid the enormous financial burdens and commitments involving the purchase of housing.

Adobe bricks:

Adobe brick building is also one of the oldest building ways. Adobe bricks are made out of loamy earth that has been moistured with water mixed with chopped straw, goat hair or other kind of fiber for enhancement, and placed into forms of the desired shape to dry. The shape is rectangle with the most common dimensions being 30x15x12 for the construction of walls 45cm thick. The way to build with adobe is the same as with normal bricks using mud as bonding material.

The advantages they have over cob are , the ease of construction, the lower cost due to the use of neat soil and the elasticity of the construction. The ideal earth for adobe making is consisted of 15%- 30% of clay for cohesion while the rest is sand or small gravel. A greater percentage of clay would lead to a greater shrinkage which would tear the brick apart, while a smaller percentage would result in brittle bricks. To make adobe bricks we put the mix into molds to take the desired shape, remove the mold and let it dry in the sun. We can also compress the mix in the mold with hydraulic presses. Adobe bricks can be used for floors, coloured with a thin layer of clay and polished with natural oil. Adobe brick buildings that have been plastered with the right plaster , generally need much less maintenance from the ones that the bricks are exposed. In an attempt to protect old adobe brick buildings, they have been plastered externally with cement. This method has failed because when the rain water penetrates the cement through a crack it cannot evaporate easily since cement blocks the breathing of the wall. As a result the plaster cracks. Adobe bricks have great thermal mass so they can absord really well the heat or the coolness. Many times, in order to have better heat insulation, double row masonry is used with insulation in between.

source:http://cob.gr/en/