Telemetry antenna mast to mount an antenna

Executive Summary

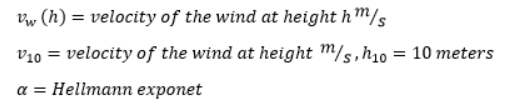

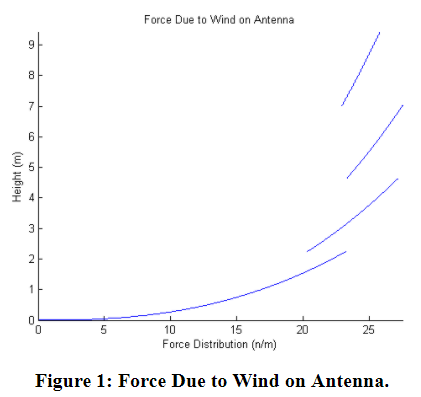

In February of 2015, team Shake & Bake was tasked with a design project. The UMBC Baja Racing Team needed a telemetry antenna mast to mount an antenna. The antenna is used to relay real-time data from their race vehicle to their data acquisition system. Dynamic Events are usually held on the final two days of competition. The first dynamic day includes the following events: Acceleration, Hill Climb or Traction Event, Maneuverability, Specialty Events (Rock Crawl, Mud Bog, and Suspension). On the second dynamic day, an endurance race is held. Our team developed an antenna system, also known as Baja Telemetry Antenna Mast (BTAM), that would mount to a Penske cab-over-engine rental truck with a 16 foot box. Our client required that the BTAM must not permanently mount to or damage the rental truck and withstand 75 mph wind speeds. In addition, the antenna supplied by the Baja team needed to be elevated a minimum height of 20 feet. While the Baja Team already had an antenna mast, it was bulky, cumbersome, and required multiple people to set up and breakdown. With a $500 budget and three month timeline, team Shake & Bake effectively brainstormed, designed, fabricated and delivered a BTAM system to the UMBC Baja Racing Team that met all requirements. The final product was completed under budget with a total cost of $317.31.

Yevgniy Morgunov working out of the UMBC Baja setup during the Baja SAE Maryland race. The field test of the BTAM system demonstrates the minimum interference to the team.

- Introduction

Shake & Bake developed a conceptual design of a BTAM system and mounting system for the UMBC Baja Racing team. The possibility of 75 mph winds raised questions regarding strength and deflection on the base and antenna mast, respectively. Shake and Bake did an analysis on:

- the amount of deflection caused by a 75 mph wind on the mast, and,

- finite analysis on the base (welds, overall strength, weight etc.)

The analysis on the base was unable to be calculated due to inadequate software. Also, the analysis shows that the antenna mast being used will deflect 44 inches at the full extension in 75 mph winds so, the system will require guy wires.

- Material Properties

Base plate

Material: ASTM A36 Steel Plate

Mechanical Properties

Tensile Strength/Ultimate: 58,000-79,800 psi (400-550 MPa)

Tensile Strength, Yield: 36,300 psi (250 MPa)

Modulus of Elasticity: 29,00 ksi (200 GPa)

Poissons Ratio: 0.260

Mast

Material: 18 AWG Heavy Duty Galvanized Steel

Mechanical Properties

Pipe1,2,3,4 Diameter: 2”, 1 ¾”, 1 ½”, 1 ¼”

Maximum Extended Length: 31’ 3”

Tensile Strength/Ultimate: 59 ksi

Tensile Strength, Yield: 48 ksi - Wind Loading Analysis

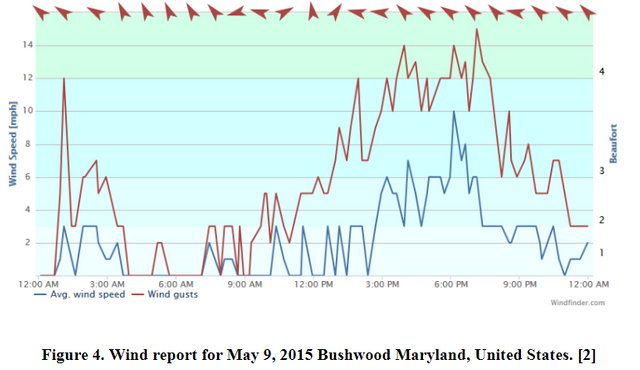

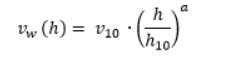

The BTAM system uses wind loading analysis to account for the vertical wind-speed profiles resulting in different wind speeds due to the wind gradient. This can create a large bending moment at the base and deflection at the top of the antenna. The velocity distribution was determined from an exponential variation in wind speed with height. [1]

where:

The Hellmann exponent depends upon the coastal location and the shape of the terrain on the ground, and the stability of the air, =0.2, was used to represent area between unstable air above human inhabited areas and neutral air above flat open coast. [2]

Force was found by calculating :

F = A x P x Cd [3]

where:

F= Force N

A = The projected area of the item m^2

P , Wind pressure N/m2, = 0.5 *ρ * V^2 *Cd (V= wind speed in m/s)

Cd , Drag coefficient, For a long cylinder = 1.205 [4]

ρ= 1.205 (kg/m3) ( Density of air at 20 °C) [5]

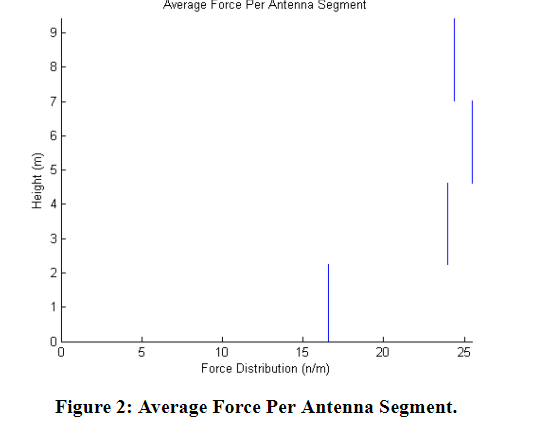

The force distribution from velocity distribution can be seen in Figure 1.

The average forces per segment:

Segment 1: 37 N

Segment 2: 57 N

Segment 3: 61 N

Segment 4: 69 N

Total force on antenna: 214 N.

The average force per antenna segment was graphed as seen in figure 2.

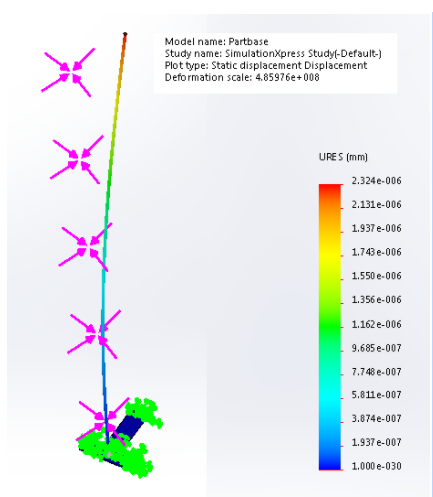

- 3D Solidworks model [6]

Mass properties of BTAM system where compiled using Solidworks Analysis to examine the 3D model as seen in Figure 3. The properties are as following:

Weight = 88.30 pounds

Volume = 312.29 cubic inches

Surface area = 5713.83 square inches

Center of mass: ( inches )

X = 23.84

Y = 37.36

Z = 76.48

Principal axes of inertia and principal moments of inertia: ( pounds * square inches )

Taken at the center of mass.

Ix = (-0.00, 0.04, 1.00) Px = 12337.74

Iy = (0.01, -1.00, 0.04) Py = 867477.59

Iz = (1.00, 0.01, 0.00) Pz = 873596.43

Moments of inertia: ( pounds * square inches )

Taken at the center of mass and aligned with the output coordinate system.

Lxx = 873592.31 Lxy = -118.19 Lxz = -1819.64

Lyx = -118.19 Lyy = 865897.42 Lyz = 36728.52

Lzx = -1819.64 Lzy = 36728.52 Lzz = 13922.02

Moments of inertia: ( pounds * square inches )

Taken at the output coordinate system.

Ixx = 1513280.95 Ixy = 78516.51 Ixz = 159174.17

Iyx = 78516.51 Iyy = 1432556.73 Iyz = 288991.90

Izx = 159174.17 Izy = 288991.90 Izz = 187320.24

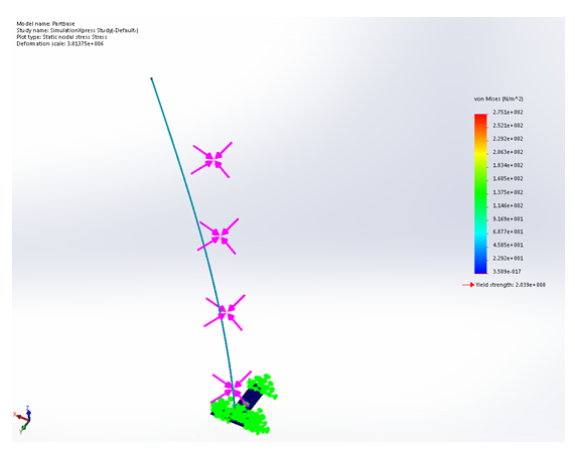

Figure 4: Von Mises N/m^2 for 1.25 inch diameter hollow pipe 390 inches tall.

Figure 5: Von Mises N/m^2 for 2 inch diameter hollow pipe 390 inches tall. [6]

Suggested Improvements

If allotted more time and a larger budget, our team would have made several improvements to the BTAM system. First of all, we would have liked to do further analysis on the system. When initially analyzing the base, we considered the welded rebar, pipe and base as one piece. Upon further consideration, we realized that the welds restricted the base from being one piece, and determined that fatigue analysis on the welds should have been done. Another analysis improvement that could have been completed was with respect to the antenna mast. We analyzed the antenna mast under a 75 mph static wind loading. The issue with analyzing the wind on one surface was that if the wind was swirling, the loading could have been coming from a variety of different directions on multiple surfaces at once. To resolve this issue, dynamic loading analysis on the mast could have been performed.

In addition, consideration of resonance from wind loading could have been evaluated. Although no shape is exempt from wind-induced resonance, it has been noted that round tapered poles are less susceptible than square ones. The natural frequency of a tapered pole varies along its length, which makes it less likely to develop overall resonance from a constant wind. The antenna fixture at the top of the mast acts as a damper to reduce resonant pole movement. In addition to the guy wires, the height of the pole should be dropped below 25 feet in open flat locations, when the pole is most susceptible to wind-induced vibration, which typically occurs around 20-40 mph. [3] Another solution to preventing resonance, is to double back the guy wires at a lower mast height. The current guy wires are long enough to allow for this in field modification.

Another improvement that could have been made to the BTAM system was to implement a better bedliner product to the base plate. The BTAM base was protected with Dupli-Color Bed Armor. It was thought that the Bed Armor would have dried hard. In reality, the Bed Armor turned out to have a more rubbery finish than expected. To improve this, protection of the BTAM base could have been outsourced to a professional bed-liner company that uses industrial grade materials such as Line-X or Rhino Liner.

Furthermore, with a larger budget and additional time, we could have developed a pneumatic piston or crank system for the antenna mast. This cranking mechanism would raise and lower the antenna mast without the need of getting onto a step ladder and raising the antenna mast manually. In turn, this would create an even safer system, thus holding paramount the safety, health, and welfare of the client.

References

[1] Heier, Siegfried (2005). Grid Integration of Wind Energy Conversion Systems. Chichester:

John Wiley & Sons. p. 45

[2] "Renewable energy: technology, economics, and environment" by Martin Kaltschmitt,

Wolfgang Streicher, Andreas Wiese p. 55

[3] "Mechanical Notes from K7NV ." WindLoads. N.p., n.d. Web. 26 Mar. 2015.

[4] "Wind Speed and Wind Pressure." Wind Speed and Wind Pressure. N.p., n.d. Web. 26 Mar.

2015. http://www.knmi.nl/samenw/hydra/faq/press.html.

[5] "Gases - Densities." Gases - Densities. N.p., n.d. Web. 26 Mar. 2015.

http://www.engineeringtoolbox.com/gas-density-d_158.html.

[6]Solidworks Mass properties and FEA Analysis

Hey you have recently received a steemstem vote.Some tips to improve your post are things such as formatting and adding a little more personality to the post. We don't usually hand out feedback but I have decided (while I still can) to give some tips to people that are newer so that they can thrive on steemit.

Firstly you use images but you do so in a kind of awkward way, to better improve your formatting you can try using the center tags like this:

<center></center>or you could use the image elements

< img src="URL">without space between angle bracket and img.but the real masterpiece is the div element as that allows text to wrap around an image, for instance:

Some text wrapped around the left

Was done with:

<div class="pull-right"></div> Text wrapped around the left