ACOUSTIC EMISSION TESTING: A COMPLETE GUIDE

ACOUSTIC EMISSION TESTING: A COMPLETE GUIDE

Acoustic emission testing (AET) is a non-destructive testing (NDT) technique that detects flaws in objects by monitoring the pattern of ultrasonic stress waves within the object through an attached set of sensors. These sensors will convert the stress waves into electrical signals and relay those signals to an external device for processing.

Acoustic emission testing, or acoustic emission monitoring, uses sound waves to detect and locate defects in materials. It is often used in the manufacturing and construction industries to detect cracks, flaws, and other defects.

Acoustic emission testing is also called Acoustic Emission (AE), Acoustic Testing (AT, Acoustic NDT, or AE Testing.

In this guide, we will use these terms interchangeably.

Acoustic emission testing is one of the most common and useful methods of non-destructive testing (i.e., testing that allows inspectors to collect data on materials without harming them).

The primary advantages of acoustic emission testing are that it allows inspectors to test a material's entire load history without damaging it.

Historically, AE has been used only for inspecting and maintaining expensive structures due to the high costs associated with it. But new developments have helped lower the cost of AE equipment, and it is becoming more accessible for a host of inspection applications.

Here is a menu to help you navigate this guide:

What Is Acoustic Emission Testing and How Does It Work?

Acoustic Emission Technique

Acoustic Emission Testing Equipment

What are the Advantages and Limitations?

What Is Acoustic Emission Testing and How Does It Work?

Acoustic emission testing is a process that uses sound waves to inspect and test materials for damage or defects. From metals to concrete to composites, it can be used on a wide range of materials. It is often used in the construction, automotive, and aerospace industries.

In an acoustic emission test, an inspector records elastic ultrasonic waves traveling through the surface of a solid material using one or more sensors.

As an acoustic wave travels on or through the surface of an object any defect it encounters can change that wave, both in terms of its speed and in terms of its amplitude. And inspectors look for these changes to identify the presence of defects.

The range of ultrasound typically used for acoustic emission testing is 20 KiloHertZ (KHZ) and 1 MegaHertZ (MHZ). (One KiloHertZ is equal to one one thousand Hertz, or cycles per second; one MegaHertZ is equal to one million Hertz, or cycles per second).

Here are a few definitions of terms we’ll use throughout this article:

Ultrasonic. The terms ultrasonic and ultrasound refer to sound waves that are so high humans can’t hear them.

Acoustic emission. The term acoustic emission refers to the generation of transient waves during the rapid release of energy from localized sources within a material.

WHERE DO ACOUSTIC EMISSIONS COME FROM?

Acoustic emissions happen when a material is under stress, either from holding a heavy load or from extremes of temperature.

These emissions typically correspond with some kind of defect or damage being done to the structure emitting them—and this damage is what inspectors are looking for when they do an AE test.

Sources of acoustic emission can include:

Phase transformation

Thermal stress

Cool down cracking

Melting

Bond and/or fibre failure

THE HISTORY OF ACOUSTIC EMISSION TESTING

Compared to other NDT methods likemagnetic particle testing or dye penetrant testing, acoustic emission testing is relatively new.

It was first used in the early 1980s as a way for inspectors to test polymer matrix composites (PMCs).

The sensors used to record acoustic emissions use a piezoelectric material. Piezoelectricity is the production of electrical charges by the introduction of mechanical stress. Imagine setting using a crane to set a slab of granite on to the top of a bus.

The heavy granite will push down onto the bus, generating stress and electrical charges. And these charges are a type of piezoelectricity.

Piezoelectricity was first discovered in 1880, by two brothers named Pierre Curie and Paul-Jacques Curie. But it was not used for much of anything until the early 1920s, when an inventor named Walter Cady experimented with using piezoelectricity for stabilizing electronic oscillators.

Around sixty years later, researchers began testing piezoelectricity for identifying defects in polymer matrix composites. Today, the sensors used for acoustic emission testing are called piezoelectric acoustic wave sensors, because they apply an oscillating electric field in order to generate a mechanical wave.

This wave then travels through a material and becomes an electric field, which can be measured by an inspector.

Although AE is a promising NDT method it is still in its infancy, and will require years of research and development before it is a completely reliable, stand-alone inspection technique.

One interesting new application for AE is using it to detect earthquakes before they actually happen, but this application is also just in the early stage of development.

COMMON APPLICATIONS AND INDUSTRIES FOR

Inspectors typically use AE to look for:

Corrosion—on the surfaces of various types of materials

Coating removal—of protective coatings put on materials

Faults/defects—for monitoring welding and for other general flaw detection

Leaks—in pipe systems or storage tanks

Partial discharges—from components subject to high voltage

For fibre specifically, AE is commonly used to test for cracking, corrosion, delamination, and breakages.

Here are some of the most common applications for acoustic testing:

Airplane longevity estimation

Bridge inspections (learn more about bridge inspections)

Concrete corrosion monitoring (learn more about corrosion monitoring)

Mine wall stability inspections

Pressure vessel inspections (learn more about pressure vessel inspections)

Leak detection in pipelines and pressure systems

Structural integrity inspections: Concrete structures such as bridges and buildings; Metallic structures such as pressure vessels, pipelines, storage tanks, aircraft structures and steel cables; Composite structures such as aircraft structures, motorsport structures and composite beams

Machines: Rotating machinery such as detecting early wear in bearings and gearboxes; Electrical machinery such as detecting partial discharge in transformers and bushings

Wind turbine inspections

ACOUSTIC EMISSION TESTING VS. ULTRASONIC TESTING

Although both acoustic testing and ultrasonic testing use ultrasound they are distinct inspection methods.

In acoustic emission NDT, inspectors “listen” for acoustic emissions from defects present in a material.

AE testing is specifically useful for determining whether a structure is overloaded, and it’s the only NDT method that can be used during manufacturing. It does not require any use of external energy (unlike ultrasonic testing), because the test material or structure itself releases the acoustic emission.

In ultrasonic testing, on the other hand, inspectors send ultrasonic waves through a structure of material from an external source. If the waves are interrupted, this indicates the presence of a defect at the point of interruption.

Acoustic Emission Technique

To use AE testing , inspectors start by thoroughly cleaning the surface of the object they want to inspect.

After cleaning, they will place acoustic emission sensors onto the structure or material that they want to inspect.

Sensors will need to be mounted on the structure with an appropriate couplant—that is, a medium to help the transmission of the acoustic signal. Adhesives or grease are commonly used for this purpose.

Once attached, the sensors will convert any stress waves present in the material into electrical signals so that they can be read by the inspector.

Inspectors feed data from the sensors to a monitor using shielded coaxial cables, displaying the information in the form of both readable results and raw data. Once the data is available, inspectors interpret it to identify where there is stress on the object they are inspecting, and look for the possible locations of defects caused by that stress.

Determinations for the amount of sensors an inspector will need for a given structure are made according to several factors, including:

The complexity of the material or structure

The size of the structure

The type of material being tested

There are two AE testing methods: transient and continuous. The transient method captures AE bursts that exceed a threshold (loudness level) and extract features such as peak amplitude, signal energy and duration of the burst. These features are then used to assess the condition of the component under test. This method is well suited for testing structures for defects such as cracks.

The continuous method captures all AE within a set time period, for example 1/10th of a second. Then, features such as average signal level and root-mean squared (RMS) values are then extracted. This method is well suited to applications where there is a lot of background AE or AE amplitude is low, for example when testing gearboxes or detecting leaks.

Acoustic emission testing can be conducted in a laboratory, as well as in-field conditions, over both relatively short durations, such as a few hours, and longer durations, such as a few months. Wireless data relay methods make it possible to analyse the data remotely.

THE KAISER EFFECT

The Kaiser effect refers to the absence of acoustic emission in an object until the level of stress that was previously applied to it has been exceeded.

The effect was first discovered in 1950, when a researcher named Kaiser found that metals could “remember” the maximum amount of stress to which they had previously been subjected.

Due to the Kaiser effect, a structure could be under damaging stress that inspectors cannot identify using AE if that stress has not exceeded the prior amount of stress the structure has experienced.

Acoustic Emission Testing Equipment

When materials are cracking, deforming or otherwise becoming damaged, they produce a kind of sound. Sometimes, these sounds are loud and obvious. Other times, they are much more subtle, and to detect them, you need to use specialized equipment. Detecting these subtler sounds through acoustic emission testing (AET) can reveal cracks and other defects that are forming which may cause significant issues, such as equipment failure, in the future if not corrected.

Here are the types of acoustic emission equipment used in acoustic NDT.

TRANSDUCERS / SENSORS / STRAIN GAUGES

These devices collect raw acoustic emission data. They are also called:

Piezoelectric transducers

Piezoelectric sensors

Strain gauges

Acoustic Wave (AE)Sensor / transducer Model List

The most common set of transducers for AE testing consists of two sets of interdigital transducers, which is a device made of two interlocking, comb-shaped arrays of metallic electrodes arranged like a zipper.

One of the transducers converts electric field energy into mechanical wave energy, and the other transducer converts the mechanical wave energy back into an electric field.

Here are some of the different types of acoustic NDT sensors:

Thickness shear mode resonator. Measures metal deposition rates.

Displacement gauges. A strain gauge that converts the acoustic emission of displacement caused by stress on a structure into electronic readings.

Accelerator gauges. A strain gauge that converts the acoustic emission of velocity caused by stress on a structure into electronic readings.

Bulk acoustic wave device (BAW). A machine that propagates waves through the substrate of a material or structure. surface wave devices

Surface acoustic wave sensor (SH-SAW). A type of BAW device used to detect acoustic emissions on the surface of a material.

Surface transverse wave sensor (STW). A type of BAW device used to detect acoustic emissions on the surface of a material.

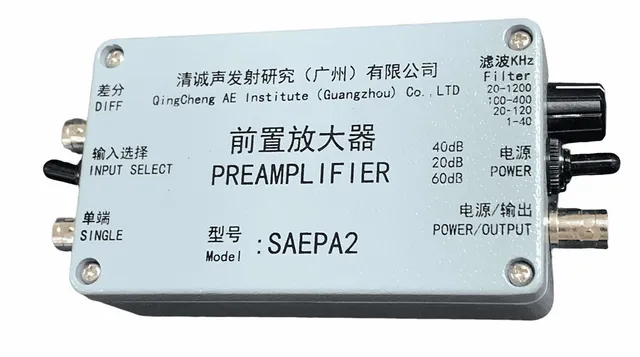

LOW-NOISE PREAMPLIFIERS

A low-noise preamplifier amplifies the output from the sensors to make it readable for inspectors.

These devices, combined with the right training, allow inspectors to identify the location of defects in a material that might not be visible to the naked eye.

What are the Advantages and Limitations?

ACOUSTIC EMISSION HAS MANY ADVANTAGES OVER OTHER METHODS. THESE INCLUDE:

Ability to detect a range of damage mechanisms including, but not limited to, fibre breakages, friction, impacts, cracking, delamination and corrosion in their early stages, before they become significant issues

Can be conducted during operation, during qualification (proof) testing or development testing

Can locate damage sources and can be differentiate these based on acoustic signatures

Global monitoring of a structure

Assesses the structure or machine under real operational conditions

A non-invasive method

Operational in hazardous environments, including high temperatures, high pressures and corrosive and nuclear environments

Can be conducted remotely

Can detect damages in defects that are difficult to access with conventional non-destructive testing techniques

HOWEVER, THE METHOD DOES ALSO HAVE SOME LIMITATIONS:

Limited to assessing structural integrity or machine health by locating issues, further inspection is usually required to fully diagnose issues

Cannot detect defects that may be present, but that do not move or grow

Can be slower than other non-destructive testing techniques

APPLICATIONS

Concrete structures such as bridges and buildings

Metallic structures such as pressure vessels, pipelines, storage tanks, aircraft structures and steel cables

Composite structures such as aircraft structures, motorsport structures and composite beams

Rotating machinery such as detecting early wear in bearings and gearboxes

Electrical machinery such as detecting partial discharge in transformers and bushings

Leak detection in pipelines and pressure systems

The acoustic emissions testing has been used in condition monitoring for civil structures and aerospace fields. It can monitor the overall structural integrity continuously during real-time operation and detects any growing defects.