You're not going to grow bugs to power your rocket. Part 2 of 2.

Welcome to the final installment of my series on rocket-fuel producing bacteria. Apart from being just plain cool, when you find out that some bacteria make hydrazine, it's temping to grow some bugs and blast off into space. However, doing that raises a bunch of problems common to bioproduction and my goal is to use this a model system to explain what those problems are, how they crop up, and how to evaluate a biotechnology program. In part 1, I talked about the issues with just growing enough bugs and getting enough hydrazine. In this part, we'll assume you've somehow overcome those problems and are ready to harvest hydrazine from your biomass. I'll go into extraction, purification, some genetic tricks you can play, compare with traditional chemical processes, and try to figure out where, if, ever, this approach would make sense.

As in the previous article, here's a review of the key points:

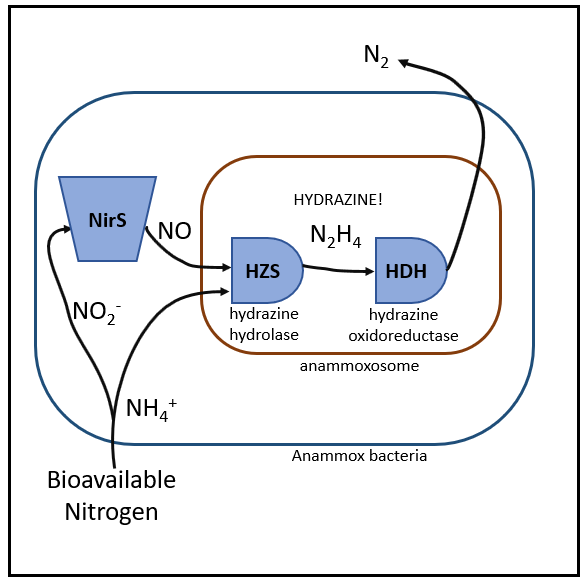

Anammox bacteria can start from biologically available nitrogen and take it all the way to N2, this is unlike the 'usual' nitrogen cycle where different bugs cooperate to perform individual steps of the conversion. They do this by:

- Combining Ammonia and nitrous oxide to make hydrazine(N2H4), with the help of a hydrazine hydrolase (HZS) enzyme

- Breaking down hydrazine into dinitrogen using a hydrazine oxidoreductase (HDH) enzyme

- This all occurs within a specialized compartment called the anammoxosome

Extraction and purification

Let's say you've got a bioreactor system filled with bugs that are happily producing the compound you want at a reasonable yield. In some cases like brewing, you're good to go. Generally though, you have to extract and purify whatever you're trying to produce. To run with the brewing example, this would be like distilling mash to make spirits or wine to make brandy.

Extraction

So, the first question you have to ask yourself is if the compound you want is excreted by the bug or if it stays within the cell. This is one of the reasons fermenting alcohol and vinegar works - they are waste products the organism does not want and excreted (that's right, beer is yeast pee!). If the compound is not excreted, then you've got some work to do. Herein lies another issue with our model system, hydrazine is exclusively internal to the anammox organisms. If you do have to do an extraction, there's lots of specific methods, but generally there's two key steps, concentration and lysis:

- Concentrate the biomass - as a rule of thumb, the more concentrated your biomass, the more efficient your extraction. It alsos increase the concentration of the compound you want, which generally aids purification. This step is not strictly necessary, but is generally a good idea. There are three big ways to concentrate suspended solid material:

a. Sedimentation - Allow the biomass to settle out due to gravity and harvest the sludge. Depending on the setup, this can be enhanced by using a settling agent to encourage the cells to clump together (coagulation and flocculation) and form aggregates that settle faster. Pretty cheap, but can take forever and doesn't give the best concentration.

b. Filtration - Run the biomass through a fine filter and harvest the residue left on the filter. Often enhanced using vacuum pumps or positive pressure. Can be relatively inexpensive, but dealing with filter clogs and reduced flow rate can be operationally frustrating. Kind of the middle ground of expense and time. It gives ok concentration.

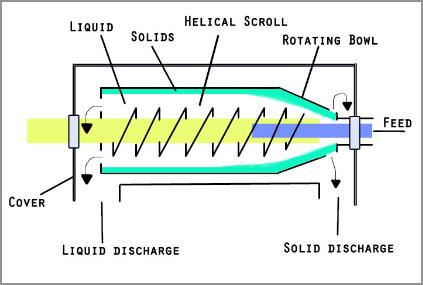

c. Centrifugation - Spin everything around really fast, taking advantage of the g-forces produced by rotation to cause the bugs to settle into a compact pellet. Energy intensive, especially for large volumes. Generally done as a batch process, but for really high value stuff, continuous centrifugation is available(and super expensive). However, it's very fast and gives good concentrations. - Break apart (lyse) the cells - Now that you have all your biomass concentrated, you need to break them apart to harvest their contents. There are lots of ways to do this. To name a few, you can alter the salinity of the water, pound them with high frequency soundwaves, attack them with microwaves, quickly alternate between high and low pressure, or just beat the crap out of them with sharp sand. The method used in any process is a combination of what's effective for that bug, what doesn't ruin the compound you want, and what machinery may already be available.

There's actually no special issues when it comes to concentrating anammox organisms, so that's nice. However, since the hydrazine is actually in a special compartment, you have to break down extra barriers when lysing the cells. Also, it's easy to imagine that the hydrazine will react with the general cellular contents (otherwise, why bother having a special room for it), and that reaction will lower your yield.

Purification

At this point you've grown the bugs making your compound, concentrated them, and even broke them open. Congratulations, you now have a soup containing traces of what you want and tons of other crap from breaking apart the cells (lysate)! You're going to want to purify it. The method you choose to use really depends on the chemical properties of the compound you want, how similar it is to other stuff in the soup, how pure you need it, and, of course, how much it'll cost to do so. Three is a whole field of separation science with its own journals, so you're going to have a lot of options. Here's a few big categories that you should know about though.

Distillation - This is our old friend which takes advantage of different evaporating points to selectively gather compounds out of solution. You probably know it best for alcohol, but it works for a ton stuff.

Liquid-liquid separation - If you have two different liquids that don't mix, it might be the case that the compound you want will selectively diffuse into one over the other (partioning ). A very common example of this is using phenol-chloroform to extract DNA and RNA from mashed up cells.

Affinity chromatography and ion exchange - The basic idea is that you have stationary phase which likes to grab onto either the compound you want or everything else. With chromatography, this 'grabbing on' changes the rate at which stuff passes through a column of the stationary phase material. If you time everything right, you can grab exactly what you want. Ion-exchange is similar, except you can usually control how well the stuff is grabbed by changing some property of the liquid phase. By washing everything out except what you want, you end up with exchange media enriched in your compound. You can then wash it with a solution which reduces the medium's affinity for your compound an wash it out (elution). This is how a lot of pharmaceuticals are purified.

Selective precipitation - This one you may know remember from high school chemistry. Imagine you really want to harvest some silver from a solution of (relatively) soluble silver nitrate. If you add a bunch sulfate, perhaps as sulfuric acid, you can precipitate out a bunch of silver sulfate.

For hydrazine, a lot of these processes may work, but they were developed to purify hydrazine from relatively simple mixtures from classical chemical engineering and probably won't work well for cell soup. For example, you can add sulfuric acid to an aqueous solution of hydrazine then crystallize out hydrazine sulfate, but in a cell soup, it's likely you'd be recrystallizing a lot of other junk. The same goes for stuff like partitioning with xylene followed by distillation.

In fact, although I use some of these methods, purification is straying away from my area of expertise. If any of you who know more (@sco, @mcw I'm looking at you), please do let me know about any horrible errors.

Genetic modifications and transgenic production

Up to this point, you've used 'natural' wild-type anammox bacteria. What about messing with their DNA to improve growth, yields, etc? People do do this with other systems. Here, you've got two points of attack, the enzymes which produce and remove hydrazine. In the first case, you could do stuff to encourage lots of production of the hydrazine hydrolase enzyme (overexpression), which would hopefully lead to an excess of hydrazine. You can also hit it from the other end and use a few different methods to reduce the production of hydrazine oxidoreductase (known-down or knock-out) to keep hydrazine from being used up.

However, dammit, there are three big issues with this.

- Although it's getting simpler all the time, it's tough to genetically engineer a bug if it's not traditionally messed with. We generally say something like we lack a good genetic toolkit. Anammox bugs are definitely not often genetically engineered.

- Overexpression will probably kill your bugs in this case. Hydrazine is actually a pretty toxic chemical, and this is likely one of the reasons it gets sequestered in the anammoxosome.

- Knock-downs are even worse, not only would you cause a build-up in toxic chemicals, but you've now interrupted one of the main metabolic strategies which lets your bugs live.

For completeness, there's two other things that genetic modification lets you do that I'd like to mention.

First, you often don't want your bug overexpressing until you've reach critical biomass. You can add triggers (inducers) which turn on any other genetic tweeks you made. You can even do fancy stuff like introduce a kill switch which makes the bugs die and break down when you're ready to harvest (autolysis).

Second, if you wanted a protein (which hydrazine is not), you can add stuff to parts of the protein that won't affect its function but make it easier to purify. A common example is adding a bunch of histidine to the end (His-tagging), which allows easy purification on an affinity column.

Transgenics

Ok, so genetically engineering our anammox bugs is a non-starter. There's still two things we can do.

Alternate expression vectors

First, as suggested by @sco in my last post, what about putting the gene for hydrazine hydrolase into a more tractable organism (like E. coli) and growing that up? This approach has some promise and is, in fact, how a lot of compounds are produced. We definitely have a good genetic toolkit for E. coli, understand how to make it grow happily, it doesn't need to metabolize hydrazine to grow, and it's got a super fast doubling time.

There's a few issues with this. One is that as a general rule of thumb, you get better transgenic expression when your organisms are more similar. While both E. coli and anammox organisms are bacteria, they come from very different phyla. Anammox bugs are planctomycetes which in highly technical terms are 'weird'. They have very unusual cell walls for bacteria and contain a bunch internal compartments, like our friend the anammoxosome. This is very different from the standard Gram-negative E. coli. A specific problem related to this is that since hydrazine hydrolase is produced in one of those compartments, it may not be produced in a usable form within E. coli.

Beyond that problem, all the toxicity issues of hydrazine come into play. In fact, they may be even worse, since it's unlikely E. coli has developed any mitigating strategies that native anammox organisms would have.

A final issue which I'm not too worried about was brought up by @alexdory. They were worried about having E. coli in a closed environment with a bunch of astronauts/Mars settlers. After all, the only time most people hear about E. coli is in relation to sickness. I'm not to worried because, as it turns out, our spacefarers are chock full of E. coli (you are too!). So long as you're not growing a pathogenic strain, the biggest problem is likely to be the, uh, distinctive smell that E. coli produce.

Direct enzyme harvesting

So far, all of the methods we've discussed involve using the bugs as little chemical factories to produce hydrazine and we've seen a number of issues with these approaches, most notably here is that hydrazine is hard to purify from a lysate, and messing with its concentration will screw up your bugs. An alternative is to use bugs to grow the enzyme which produces hydrazine, purify the enzyme, and then use it in a non-biological system to catalyze hydrazine production in a cleaner system. Perhaps you have or have seen some laundry detergent which contains enzymes to break down stains? That's pretty much exactly the kind of thing I'm talking about.

In this case we would almost certainly want to grow the enzyme in an expression vector, like E. coli. Let's assume that we've ironed out all the issues with getting usable proteins to grow in our vector. Ideally, we'd express them extracellularly, but that may not be possible, if so, we still have to go through the extraction steps I mentioned earlier. Purification of proteins is a lot more straightforward (particularly when you're engineering them) than other metabolites, so that probably won't be a problem. The problem you'll run into is the stability of the protein outside of its normal environment. Some proteins are really happy so long as they're at the right pH. Others simply won't work unless they are in their own personal Goldilocks zone. Another class are ok-ish outside of their comfort zone, but don't last very long, they break down 'by design' and, in their natural environment, are continuously regenerated by the cell until no longer required. I have no idea which of these classes hydrazine hydrolase falls into and it would be the most important criterion for this approach.

Assuming all of that goes ok, you could get a concentrated pile of the enzyme, optionally attach it to some sort of support/handling medium, and just dose tons of water containing ammonia and nitric oxide to produce hydrazine. Since this solution is not a soup of lysate, traditional hydrazine purification techniques would work.

Traditional production and does this make sense?

Finally! We have a system that at least theoretically could produce significant amounts of fairly pure hydrazine, if you get past a bunch of caveats. It's also complex, expensive, and not guaranteed to work. The annual global production of hydrazine is pretty small and there's a lot of industrial processes which can make it, with various tradeoffs between simplicity, cost, and efficiency. I would be surprised if a biotechnical process would be competitive.

However, there is a situation in which this might make sense, and it rests on one premise: What if the goal were to remove nitrogen, rather than make hydrazine? This sounds a little weird until you know that many wastewaters are high in nitrogen and it's kind of hard to remove. You're generally limited to slow biological removal or energetically expensive air stripping. I do not know if it is feasible, but it is certainly worth looking into using harvested hydrazine hydrolase to remove nitrogen by producing hydrazine. As a bonus, you could burn the energetically dense hydrazine and maybe become an energy producing facility. There is one great big giant issue with this, though, you definitely don't want hydrazine ending up in your water supply. It would be far less damaging to release untreated high-N wastewater than release some with even traces of hydrazine, so you'd have to have really efficient purification and multiple, well-designed safeguards. I am not sure at this point that the risk would be worth the reward.

Being A SteemStem Member

You just planted 0.65 tree(s)!

Thanks to @effofex

We have planted already 4376.41 trees

out of 1,000,000

Let's save and restore Abongphen Highland Forest

in Cameroonian village Kedjom-Keku!

Plant trees with @treeplanter and get paid for it!

My Steem Power = 20735.12

Thanks a lot!

@martin.mikes coordinator of @kedjom-keku

I love the quality of your posts. Great work.

Thanks.