Learn with steem || Tutorial class 5 || Mechanical Engineering|| subject - Manufacturing process-||burbsteem25|| by @deepak94

Namaste steemit

Hello friends, how are you all, hope all is well, today I am going to write my sixth post about my subject. Today in this post we discuss the different press operation in the manufacturing process. So let's start with the topic.

Press working. Power presses are used to produce large quantities of articles quickly accurately and economically. Cold working of mild steel and other ductile materials are used.

Press operations.

Press tools designed for carrying out the following operations.

- Piercing (removal of a local piece of the material to form a full of same space).

- Shearing

- Blanking (production of the contour in the flat bank) clipping sharing etc.

- Bending

- Curling

- Drawing (production of deep Cup component)

- Deep drawing, shallow drawing, redrawing.

In addition, the operation of cupping, Lansing notching coining, and trimming may also be carried out.

| Shearing |

|---|

The metal is brought to the plastic stage by pressing the sheet between two sharing blades.

| Piercing (Punching) & Blanking |

|---|

- Piercing and blanking are shearing operations.

- In this operation the piece of metal sheet or any sheet is punched out and it becomes the workplace and many of the major burrs or undesirable features should be left on the remaining strips this operation is called punching.

- In piercing operation remaining part acts as a workpiece.

- Both are done on some form of a mechanical press.

Note- In blanking, the angle of shear is provided in DIE.

| BENDING |

|---|

BENDING REFERS TO THE OPERATION OF DEFORMING A FLAT SHEET AROUND A STREET AXIS WHERE THE NEUTRAL PLANE LIES.

EDGE BENDING

V -Bending

| Embossing |

|---|

Embossing is the operation used in making race figures on the sheet with its corresponding relief on the other side.

| Coining |

|---|

Coining is the cold forging operation in which we emboss the structure on the top layer of the metal.

The pressures involved in coining are very high 1600 megapascal.

with the help of the Coining operation we make coins, medals, and many of impressions on decorative items.

| Trimming |

|---|

In operations such as drop forging and die casting a small number of extra metals to get spread out near the parking plane which term as a flash.

| Notching |

|---|

Notching is a method to cut a specified small portion of metal toward the edge of the stock.

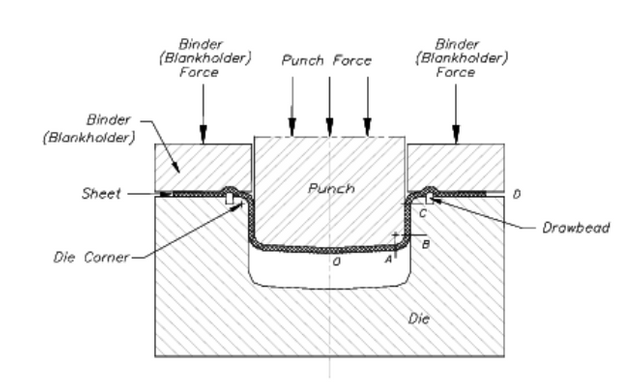

| DRAWING |

|---|

DRAWING IS THE PROCESS OF MAKING CUPS SHELLS AND SIMILAR ARTICLES FROM THE METAL BLANKS.

| STAMPING |

|---|

It is an operation of printing letters numbers and other figures on the metal sheet using stamping or roller dies.

| CRIMPING |

|---|

This process which used for producing the flutes or corrugations. It is very often used for joining metal pieces together as stove pin joints

I hope you all liked my tutorial series about mechanical engineering subject and please tell me in the comments, what you liked in this quick tutorial series.

Thank you for contributing to the #LearnWithSteem theme ( #learnwithsteem, #tutorial, and #lesson). This post has been supported by @cryptogecko using @steemcurator09 account. We encourage you to keep publishing quality and original content in the Steemit ecosystem to earn support on your content.

Regards,

Team #Sevengers