Recycle Old Plastics and Create Your Own 3D Printer Filament With the ProtoCycler

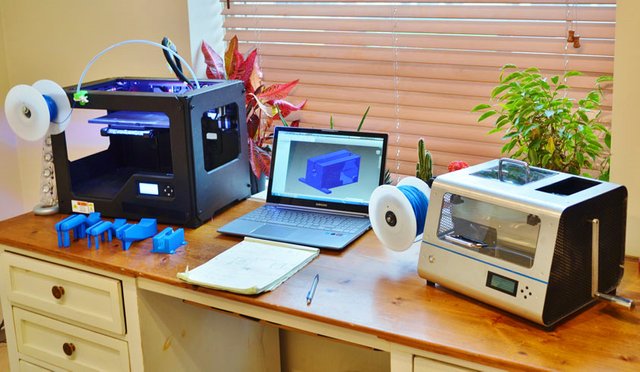

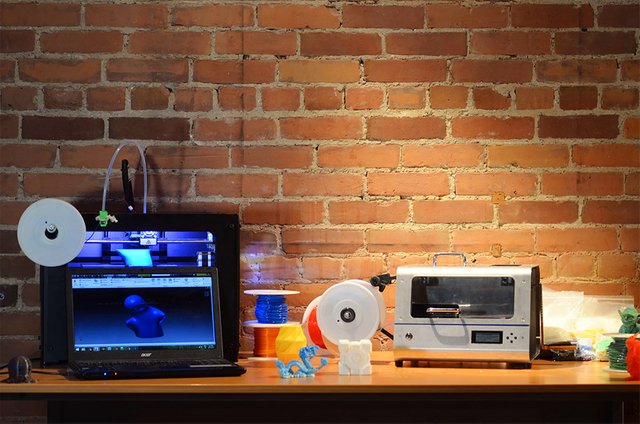

The ProtoCycler is a 3D printer filament maker that has been in development for quite some time and I have been following and waiting for the final product to become available and get one to go along with my 3D printer. The device is being developed by a Canadian company called Redetec and they are finally reaching the stage of finalizing everything and starting to ship their filament maker to everyone that has preordered it.

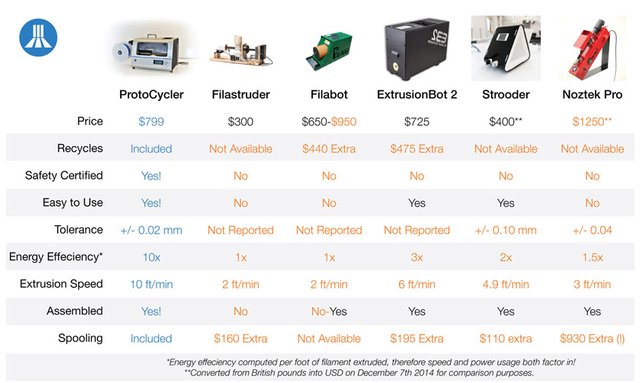

The ProtoCycler is not the first consumer oriented filament maker, nor it is going to be the last one on the market, it is not the cheapest either, however for me it is the best solution for my needs. The reason for that is the fact that the device comes fully integrated with a grinder (to grind old plastic objects or failed 3D prints) and then use the grinded plastic as a source for the filament maker instead of having to rely on pellets for that. Also the device has a built in spooling mechanism that allows you to easily get the filament it produces directly wound on spools and ready for use on your 3D printer.

Redetec is promising some really nice specifications of their device when compared to the competition, mainly better extrusion speed and better energy efficiency. So essentially it makes more filament in shorter period of time while saving on power costs when compared to other alternative consumer filament makers already on the market. All that comes with a similar or just a slightly higher price, but you get all in one solution. For me the grinder part is especially important as it should allow for easy recycling of non-needed plastic things and not only work to recycle failed on not needed anymore 3d prints turning them back into new flament for use on the 3D printer.

The recycling of old plastic is really the most attractive feature that in my opinion every filament maker should come bundled with, though unfortunately no other comes with that and they are not even offering it separately. Essentially other filament makers are designed to work with plastic pellets as a source of the plastics that you will use to create new filament. This also works and allows you to make cheaper 3D printer filament than what it would cost you to buy the filament directly from a company making or reselling it. Then again the killer feature would be to be able to just take those plastic bottles that you would normally throw away and turn them into new filament, or to recycle old plastic toys that you no longer need... recycle and reuse plastics instead of just throwing it away!

The ProtoCycler is still available at a price of $699.99 USD for pre-order + shipping cost, though as soon as shipping begins (hopefully very soon) it should go up to $799.99 USD. The device is available in black and silver color with the only difference being the color of the enclosure.

Features of the ProtoCycler

First consumer extruder with UL certification

First extruder with grinder for built in recycling

First extruder with diameter feedback and computer control

Distributed Spooling

Automatic start up and shut down

Full Manual mode for hacking

Open source software and community

Beautiful brushed aluminium enclosure

Patent pending MixFlow extrusion technology

Technical Specifications

Diameter tolerance: +/- 0.05mm

Extrusion speed: Up to 10 ft/minute

Electrical usage: 60 W average

Dimensions: 14" x 12" x 10"

Grinder input: 5" x 5"

Hopper Capacity: Expandable

Max Temp: All metal hot end for most plastics under 300 C

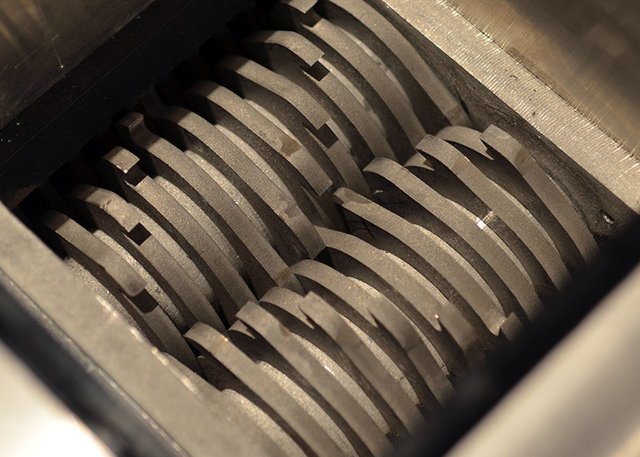

The grinder that allows you to crush plastic objects into small parts that you can then use as a source material for creating new filament is hand operated, so you need to rotate a lever on the side of the device to recycle old plastics. This should double not only in doing good for the nature by not throwing more plastic trash, but also keeping you fit by doing some physical exercises as well. The operation of the grinder is not automated with a motor as it could become dangerous if you are not careful when operating it and hand cranking it should be generally safer for your fingers if you are not paying much attention.

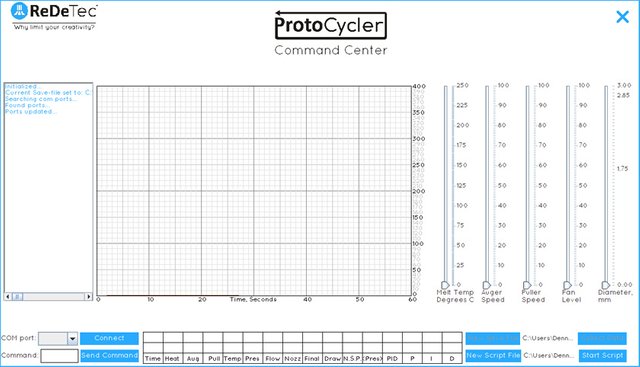

There should be no dangerously hot parts exposed as all the heating and extruding elements are enclosed in the metal case of the device, but you should still be careful when using it as the extrusion nozzle can be really hot and the same goes for the new filament that goes out of it. By the time the filament thread reaches the spool where it will be wounded it should be cool enough to be safe to the touch. Another very interesting feature about the device is that it should be able to produce different diameter filaments all without the need to change the extrusion nozzle. The ProtoCycler should be able to extrude 1.75mm, 2.85mm, 3mm, or any other filament diameter that is under 3.5mm and that should be easily controlled from the software of the device.

The software of the device should be easy to be used by novice users and at the same time provide enough flexibility to allow for more advanced users to be able to experiment with the setting for various plastic materials. By default the software should support automatic extrusion of ABS and PLA, but there are numerous settings that you can play around with to allow you to try turning those PET bottles into new filament that you can then use on your 3D printer. Combinations between different colors and even types of plastics or mixing something more interesting should also be possible, though it will require more time and effort to figure out what will work best in each specific case. The filament maker should be able to produce 1 kilogram of new filament from the plastic you feed it with in about 2 hours, though that could also depend on what settings and type of plastic material you are using.

So if you are looking for a filament maker machine to go along with your 3D printer I do recommend that you check out The ProtoCycler as it is really going to be one of the best choices in my opinion. Especially now that the device is finally almost finalized and soon should start shipping and the long wait is almost over, as I've said I've been following its development almost from the start and that was quite a while ago. I can't really wait to get my hands on one of these and start experimenting with different plastics and making my own filament out of old plastic things and then try printing with it...

All images used in this post are from the official Redetec website!

If you have a question or want to add something, then please leave a comment below.

Did you like what you have just read? Check my other posts on steemit @cryptos

If you like what I'm doing for Steem and on Steemit you can support me as a Witness

Will it off-gas anything toxic?

Toxic - no. It depends on the plastic type, some plastics such as ABS may give off pottentially dangerous fumes when heated to a high temperature needed to melt them, so it is recommended when working with ABS (printing it or making filament) to be in a well ventilated area.

No and yes. If it has ink it will. If not it will only be C02+H2O .

That's the second best use of plastic I've seen... (first one is chemical reduction to diesel-like fuel). Nice...

Never ever again waste a good piece of useless plastic by throwing it on the trash :)

now that is sweet!

Yes, it is... really can't wait for them to finally start shipping soon.

LOVE, Love, love, this idea/product. As I was shredding paper to use in a papercrete (shredded paper + portland cement) project the other day, I found myself wondering if there was a way to 'shred' plastic to be used in a way that I use shredded paper. Will have to keep an eye on the development of this and perhaps one day get one of these 'machines'.

Thanks for this post. ~ljl~

I wish to have more information. This will be a huge help for my startup project! This is awesome, similar to precious plastics.

I really need this.