Repair work in the factory of the future

I have had my Ultimaker 2 for a few years now and it has turned out to be an excellent investment. it runs smoothly and with no troubles almost every time.

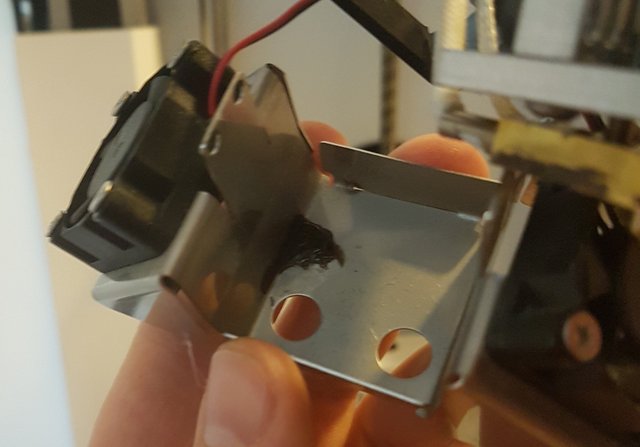

But even the most stable machine needs a little loving care once in a while. Having worked on the figurines for my Phill from GCHQ - merchandise project I have run it quite a lot and sometimes prints go bananas. after a few mishaps the hotend(where the hot plastic comes out) had become somewhat cluttered with carbonised plastic, so I decided to take it apart and clean it out

One thing that is important to remember when taking apart stuff, is to go slow and make sure to place all the removed parts in an orderly fashion so that you may find them easily when assembling. I am not very good at that but I try.

It turned out that quite a large chunk of carbonised plastic was sitting on the inside and while it doesnt pose any immediate problems for the extrusion it is not supposed to be there.

Here you can see part of it. Before I started prying it loose it was all around the hole as well. It came off pretty easily though so not big problem. I did find that the place where the tube goes into the hotend was a bit loose, so i got that tightened. maybe it helps, maybe it doesnt matter. as i said, it is not like I was having any real problems with the printer, just a bit of maintenance.

Until next time.

Im EvilHippie, a compulsive creative and jack o' trades. If you want to know more about me, check out my introduction post here

If you like what you see, feel free to upvote, follow and resteem

or you can check out my accounts on these sites:

Youre welcome to like or follow me there as well.