Fiber Optics: The world we live in..

I'm going to step outside the normal silver market related posts. We are going to shed some light on an interesting topic. A few years ago I started working on fiber optics. Mainly focusing on aerial fiber that is ran in the secondary space of telephone poles. To give you a brief overview. Fiber is a strand of glass roughly about the size of a hair folical. The glass allows light to travel through it which provides "signal" to what is on the receiving end. Due to the glass composition it is very easy to snap/break when issued a hard bend. On the other hand the glass is a benefit because it can carry signal for miles! The bare glass fiber is insulated with a plastic type of jacket for protection and color to identity. That plastic jacket is then woven together with other strands of fiber to create one solid cable. There are many different sizes of fiber cables ranging from one fiber to hundreds.

Fiber is the what runs our world! Most people don't even realize it. Majority of all the larger hotels, business, industrial buildings, cell phone towers, homes(Verizon), cable companies, atms and malls use fiber to operate. It can be ran in the secondary space of telephone poles and also under ground. If someone went on the busiest street in a city. Took down a fiber case that housed hundreds of connected fibers. Took out a hammer and smashed the tray of fibers. ALL of the businesses, street lights, traffic lights, and cable would shutdown entirly. It's honestly amazing!!!!

This week I worked on a fun project for a large food equipment distributor. We linked together four of their low voltage electrical closets with a 12 count fiber. The fiber we ran is "spliced" with a female connector. Allowing a fiber optic cable to be plugged into it. The other end of the fiber optic cable will plug into the source. The source would be whatever type of equipment they are hooking up. The electrical closets here were responsible for the wireless internet in that general vicinity. Connecting all four closests to the main server room will boost wireless signal dramatically through out this huge facility.

I am going to show you exactly what this kind of work looks like. The equipment alone is extremely fascinating. As well as expensive !!! Check out the photos below for the walk through....

Here is one of the twelve fibers on the cable we ran. This is the blue fiber which is always put in the first position. What you are seeing here is the plastic jacket around the glass fiber.

The blue jacket is now stripped off. It shows the bare glass fiber. This bare fiber needs to be stripped of a slight plastic residue that is left behind from the blue plastic insulator.

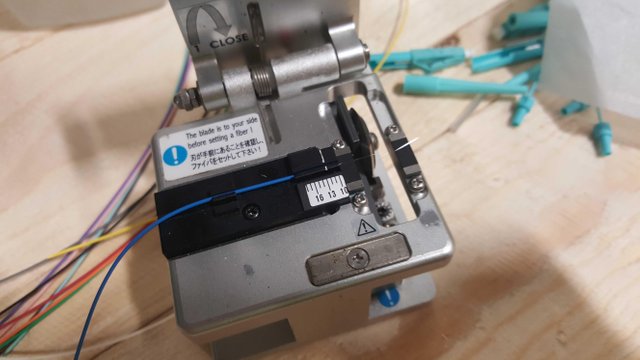

Once the fiber is stripped enitiry. It is then cleaned with a thin whipe that has been washed with alcohol. The fiber is placed in a "cleaver". This is a cutting tool that makes an absolute flawless square cut. It is impossible to use a hand tool to make a square clean cut on fiber.

Close the lid to the cleaver while the fiber is in the slot. Push the cutting wheel forward and you can see the fiber is cut square. The throw away end of the fiber rests on the right side of the cleaver. Which needs to be thrown away immediatly. If it remains on the table and your hand or fingers run across it. The fiber can actually stick right into your skin like a glass splinter!

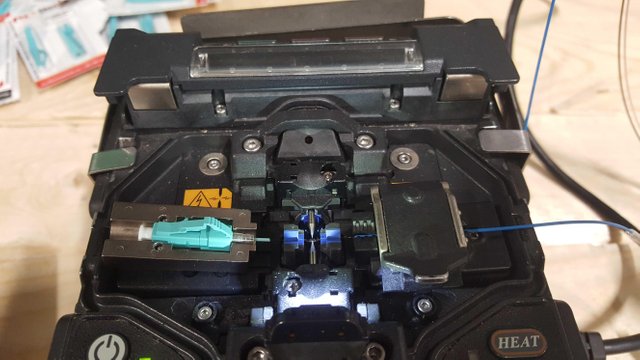

Now the fun part! The splice machine in action! This piece of equipment costs roughly $15,000. What I am doing here is splicing a connector onto the bare fiber. Actually fusing the two pieces of fiber together. This piece of equipment is known as a fusion splicer. I have the connector on one side in a "shoe" or holder. While the raw fiber is held down by a shoe and rests in a V groove. Directly in the middle of each shoe are the prongs that fuse the fiber together.

Once each fiber is in position. You close the door on the top of the machine and a camera on each fiber displays an image. The image shows the cleanliness of each fiber. As well as the cleaved edge. If either are sub par the machine will refuse to splice.

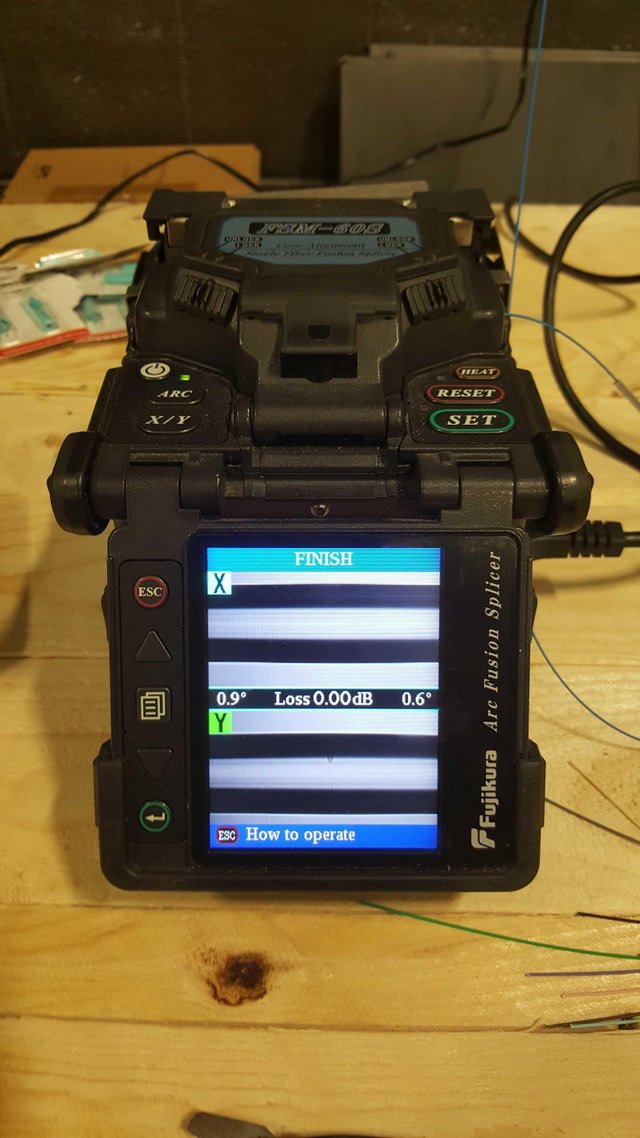

With a click of one button on the machine. The screen shows a strong burst of light then yields the end result. The image shows if there are any weak spots in the spice. As well as a DB loss. The DB number indicates if there will be any "loss of light" due to the quality of the splice. Anything under .15 DB would be unsatisfactory. Once you lift the door up on the machine. The splice machine does an automatic strength test. Lightly pulling on each end of the fiber to make sure the splice holds.

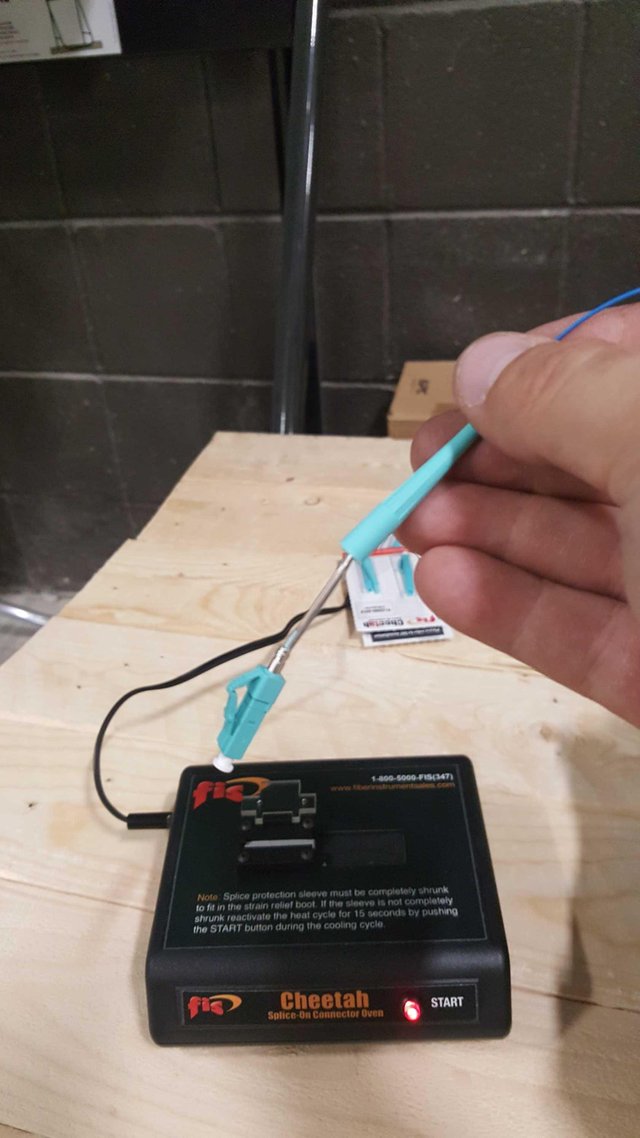

Once the splice is completed you slide over a clear tube which acts as a strength member. The tube has a tiny piece of thin metal running through it. Once the plastic tube is over the splice you place it in a small "oven." This oven heats up the plastic tube melting it onto the splice. This keeps the splice in tact and strong! The oven runs for about 15 seconds until a red light indicates it is completed.

After the clear tube has dried you then pull over a rubber type

fitting that protect the end of the connector from any hard bends. As well as offer a strong layer of protection.

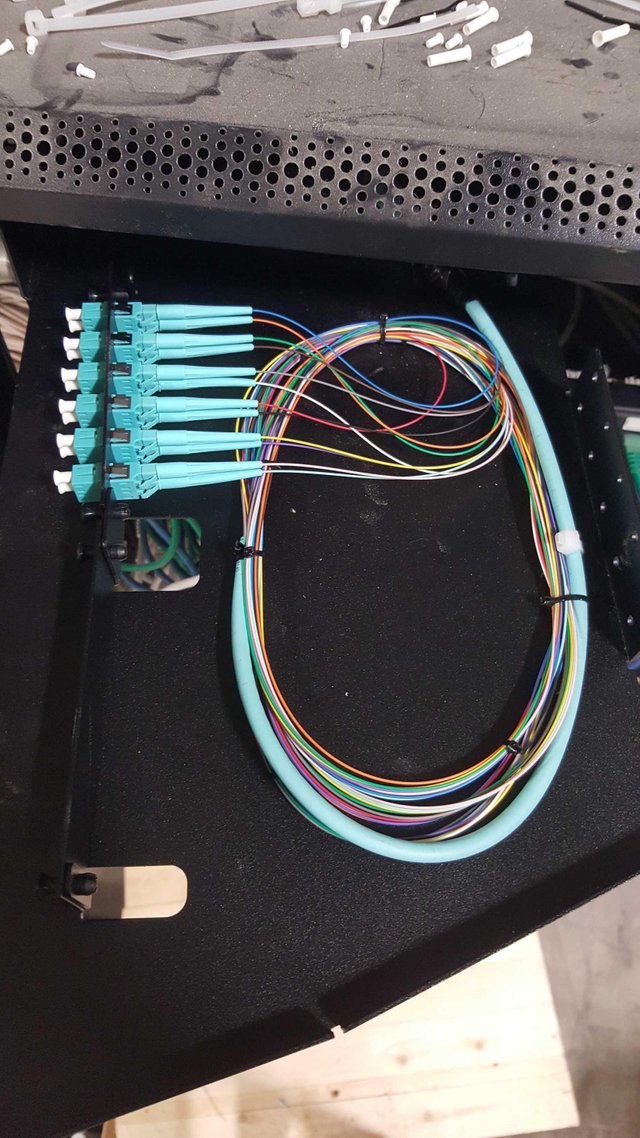

Here is the final product!! After splicing 12 fibers to 12 connectors. You then plug each connector into the corresponding ports. Once this FTP is installed into a metal rack you can access all the ports from the front. Simple plug and play.

In order to complete a job like this you really need to have a well functioning work station. I try to make it as comfortable and work friendly as possible. There is a lot going on at once. Here is a couple few photos of my work station as well as the final view of one of the rack mounted FTP's.

This is a unique article! It breaks down and explains the workings of something not a lot of people are aware of. It is proof of just how far technology has come. The world and how we live today operates through FIBER OPTICS.

It would be great to RESTEEM this article and share this information with the community. Some may find it interesting while others no so much. To me it's FASCINATING!

If you enjoyed this article please RESTEEM UPVOTE and FOLLOW!

Follow me on Instagram: collectbulliondotcom

Brought back my electronics and communications engineering days :D

The splicers are pretty expensive equipments as splicing two FO cables is a precision task. Its no rocket science but one needs patience if it has to be done manually.

@hashcash the precision in this machines is just amazing. Upkeep is clearly a big part of them functioning properly. I don't have much experience with the older V groove machines. Which are more manual.

thanks, that was interesting!

Thanks @cyber.explorer!

Thank you for your continued support of SteemSilverGold

Blue, Orange, Green, Brown, Slate. LOL. Oh and I can't forget Why Run Backwards You'll Vomit. That's awesome. The equipment has come a long way. We have hand tools to cut fiber and add LC ends but rarely use them (always tons of spares laying around). Thanks for sharing. Had to resteem this one.

@vgholdingsllc I specifically thought of you when I was writing this as we have discussed common interests. Glad you enjoyed this. Took me a while to write up but it will forever be on record now 🤜🤛

This article was better than some of the MOPs I've read. LOL. I thought about doing something similar to this. Taking a walk around my switchroom starting in the old Telco area and continuing though to the newest sections. Boy would that be a write-up.

Lol! Honestly though, we are around this stuff so it's not a big deal. When I go and tell my friends and family. They look at me like I have 2 heads. This is how our world operates 100%. With out it there would be nothing!! The world would stop. People deserve to be informed....

I would love to see some articles about your head end. .

Fascinating article. Brought me back memories, not of fiber optics, but of telecommunication around fifty years ago. Good and old times.

@ronaldoavelino Glad you enjoyed it. Yes alot of cross over with telecommunucations here!

Great post buddy, i have never seen this being done before. Learn something new everyday. lol

Thanks @firecajun9262. Took me a while to write up but I figured it could be worth it.

Very interesting indeed, and I thank you for sharing! Asthma to me the ssg community has some of the smartest in it!

Appreciate your support on the article! Ssg community reminds me of a well rounded "jack of all trades" community. Metals tend to attract those kinds if individuals. Speaking only from my experience.

Fiber optics are more secure than most wiring, and are immune to EMP, so everywhere they go in, makes the communication system they become part of, more robust and reliable. I use a lot of fiber optics for communication on CNC machinery, for data reliability in a high noise environment.

Enjoyed the post!

:)