Gas Turbine: Its working principle and Brayton cycle

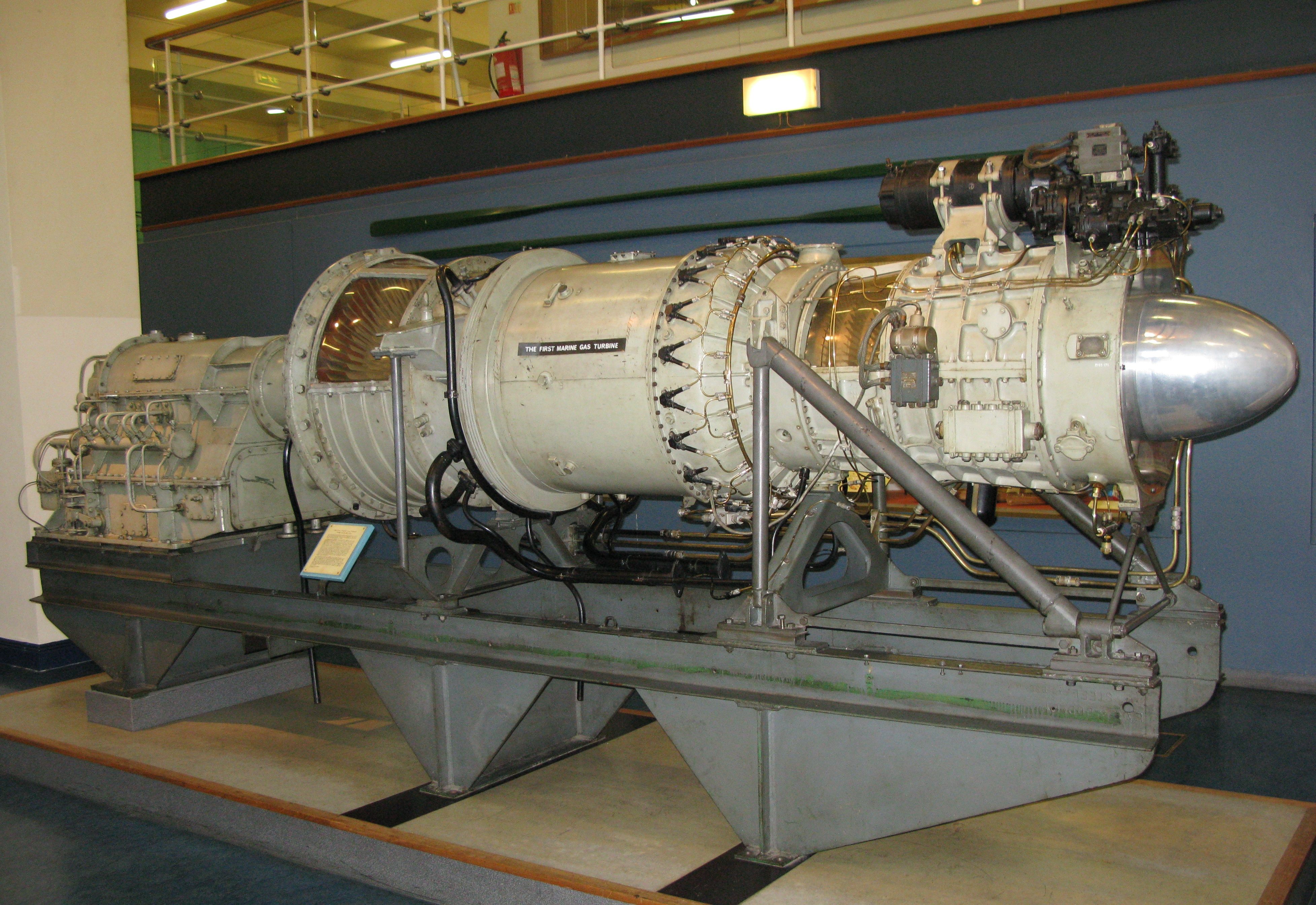

A gas turbine is an internal combustion or continuous combustion engine, so it is also referred to as combustion engine. The main use of a gas turbine is in the electricity generation which is dated back to 1939.One of the most used technologies for generation of power in today’s world are gas turbines.

Gas turbines are typical internal combustion (IC) engine which produces hot gases as a result of burning of air-fuel mixture. These hot gases produced spin the turbine which later results into power production. Gas turbines derived the name not from the fuel itself but from hot gas production during fuel combustion.

Combustion occurs intermittently in reciprocating IC engine while in gas turbines engine, combustion occurs continuously .Fuels being used by gas turbine includes fuel oils, natural gas and synthetic fuels. Aircrafts, ships, electrical generators, trains, pump, gas compressors and tanks are being powered by gas turbines.

There are two types of land based gas turbines: The heavy frame engines and aeroderivative engines. Heavy frame engines are always physically large and known for their low pressure ratio. The ratio of the compressor discharge pressure and the pressure of the inlet air is referred to as pressure ratio.

The aeroderivative engines as the name implies are obtained from jet engines and at high compression ratio they operate. Aeroderivatives are firmly packed together and are very useful where the power outputs needed are small. Larger amount of emissions can be produced by large frame turbines as a result of higher power output they produce. Therefore, it must be designed in a way in which we can have low emissions of pollutants.

Gas turbine working principle

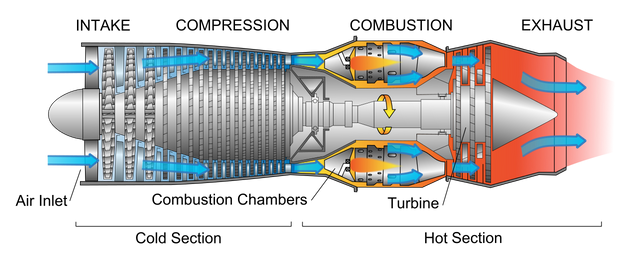

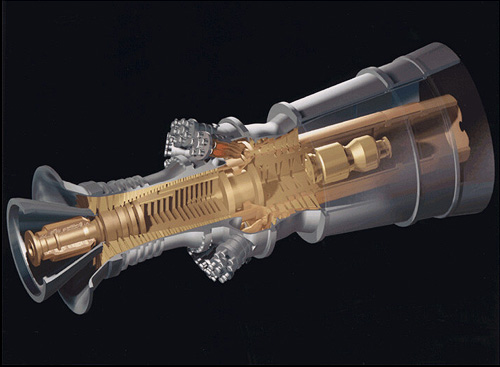

Gas turbine is made up three primary sections which are mounted on the same shaft. The sections are the compressor, the combustion chamber and the turbine.

The combustion system: It comprises of fuel injectors ring which functions by injecting fuel of steady stream into the combustion chamber. Inside the combustion chamber the stream of fuel is mixed with air which burns at a temperature greater than 2000 degree F. A high temperature is produced as a result of the combustion which results into high pressure gas stream since temperature and pressure are directly proportional. The gas stream of high pressure enters into the turbine section.

The Turbine: It is made up of rows of stationary blades (nozzles). Due to the expansion of the hot combustion gas through the turbine, the rotating blades of the turbine spin. The rotating blades perform double functions which are; driving of the compressor in order to deliver more pressurized air into the combustor and generation of electricity as the rotating blades spin the generator. About 45-35% of the power produced by the turbine is used by the generator to generate electricity while the remaining 55-65% is used to drive the compressor

Performance of gas turbine

There are four thermodynamics processes in which the gases undergo in a gas turbine. These are isentropic compression, isobaric combustion (constant pressure), isentropic expansion and heat rejection. These processes are what make up the brayton cycle. The major operation through which a gas turbine works is Brayton cycle. It uses air as the working fluid.

In Brayton cycle, there is an irreversible change of mechanical energy into pressure and thermal energy as the gas experience compression in a real gas turbine. The specific volume of the gas increases in the combustion chamber as a result of heat added. This also results into slight pressure loss. Another irreversible energy transformation occurs during expansion of the gas through the turbine’s stator and rotors passage. During the heat rejection process, fresh air is taken in.

In a jet engine, in order to drive the compressor and other component, only enough energy is needed and it is extracted from the flow. The remaining gases with high pressure are used to propel an aircraft of a jet.

The higher the rotation of the shaft the smaller the engine in order to reach the required blade tip speed. The maximum pressure ratio that a turbine and a compressor can attain is determined by blade tip speed. With this, maximum power and efficiency that the engine can obtain is limited. For a constant tip speed, the rotational speed must be doubled if the diameter of the rotor is reduced by half.

Turbine Engine Challenge

The major challenge experienced by turbine engine design is known as creep. This creep is caused by high temperature. Turbine materials are damaged as a result of stresses of operation through creep mechanism. Creep becomes significant as a result of increased temperature which gives improved turbine efficiency.

How to limit creep

In order to limit creep, turbine blade designs with thermal coating and super alloys with solid solution strengthening and grain boundary strengthening should be used. Thermal damage and oxidation are limited by the use of protective coating.

The temperature exposure of nickel super alloy is been limited by thermal protective coating. With this, the creep mechanism experienced by the blade is reduced. Efficiency losses as a result of build up at the outside of the blade is been limited by oxidation coating. To improve the strength and creep resistance, blade with nickel based coating is used.

Advantages of gas turbine engines

It is smaller than most of the reciprocating engines operating on the same power rating.

Compared to reciprocating engines, it has a high power -to- weight ratio .

It produces less vibration than the reciprocating engines as a result of smooth rotation of the main shaft.

It has low cost of maintenance compared to the reciprocating engine because of fewer moving part.

It has great reliability especially where power output required is high.

It requires low cost and consumption of lubricating oil.

It can make use of different forms of fuel ranging from synthetic oil to natural oil.

It emits low toxic emission.

Disadvantages of gas turbine engines

Than the reciprocating engines, it has longer start up.

It is less efficient than the reciprocating engines.

As a result of exotic materials used for the engine, the cost of the engine is high.

Compared to reciprocating engines, it is less responsive to demand of change in power.

You can obtain more information about gas turbine by watching the video below

Image Credit

1

2

3

Note:All images are from free source

References

- https://en.wikipedia.org/wiki/Gas_turbine

- https://www.wartsila.com/energy/learning-center/technical-comparisons/gas-turbine-for-power-generation-introduction

- https://energy.gov/fe/how-gas-turbine-power-plants-work

- https://www.gepower.com/gas/gas-turbines

- http://www.edisontechcenter.org/gasturbines.html

Congratulations! Your post has been selected as a daily Steemit truffle! It is listed on rank 11 of all contributions awarded today. You can find the TOP DAILY TRUFFLE PICKS HERE.

I upvoted your contribution because to my mind your post is at least 24 SBD worth and should receive 40 votes. It's now up to the lovely Steemit community to make this come true.

I am

TrufflePig, an Artificial Intelligence Bot that helps minnows and content curators using Machine Learning. If you are curious how I select content, you can find an explanation here!Have a nice day and sincerely yours,

TrufflePigI really appreciate your in depth posts! Keep doing what your are doing 👍🏽.

@mxjx check this steemian out!

Thanks @portiajay