3D Printing Parts for a 1887 Pipe Organ

Here we have a Wm. Johnson & Son (Opus 677) tracker pipe organ from 1887. Moving around inside it is probably the closest a human can get to feeling like a gerbil in a maze. One of the design flaws was having the tracker linkages for the Swell directly above the access point for the walkboard over the Great. Over the last 100+ years these delicate wooden squares have been bumped occasionally and repaired poorly. Binder clips are not industry standard.

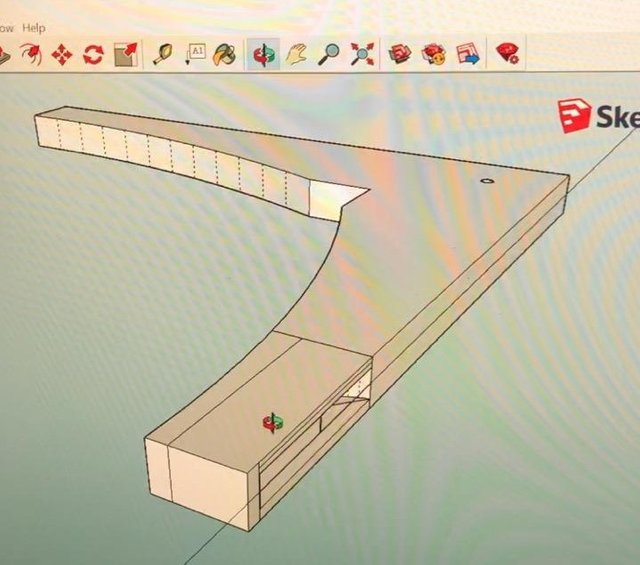

We only recently began caring for this instrument and one of the first calls we received was for a key on the Swell that was no longer working - a binder clip had fallen off. No spare squares (the L-shaped piece of wood) were to be found in the organ, and checking a few suppliers we found that no perfect match was available. We took a sample from the organ back to our facility and our man Derek had a go at rendering the part in SketchUp .

We have a Lulzbot 3D printer and I've been doing all prints from PLA lately because they don't shrink (not much at least) and the plastic is far stronger than ABS. We printed a prototype and it seemed strong, so we printed a half dozen and took them down to try them out in the pipe organ. The replacement squares worked perfectly! The weakness is actually in the wood linkages - they are so brittle after 100 years that working with them tends to break them.

Thought this was a pretty cool 'old meets new' situation. The wood squares from 1887, when not disturbed, still work perfectly well. I wonder if the plastic replacements will last half that long....