Maybe you don't need to talk about colors in front of you because you know colors very well. But I will discuss what color firstness is actually. Let's discuss. So the color first match is a color when we wear a colored fabric or a drawing garment, how much color can it clash with our body or how much color can it come out when we wear it outside in the sun. The barrier that will prevent the color from rising is basically what we call resistance or color resistance. The better the color resistance of a fabric, the better the color quality of that fabric because when we wash a garment after bringing it home. So many colors are removed from those garments but what will prevent these colors to come out is basically what we call resistance or color first match.So when a garment from Dhaka sent to our testing laboratory, it basically sent us a cut piece as a fabric. So we basically cut this cut piece to 35 inches into 35 inches first. Then we put a US in there to measure the stylability or we call it the spiciness or we call it to measure the twist. Then we take it to the wash and we use some chemicals to wash it. I have mentioned the names of the chemicals mentioned below.

👉Lhistory diene monohydrochlori monohydide.

👉sodium chloride

👉Disodium orthophosphate Dekha hydrate.

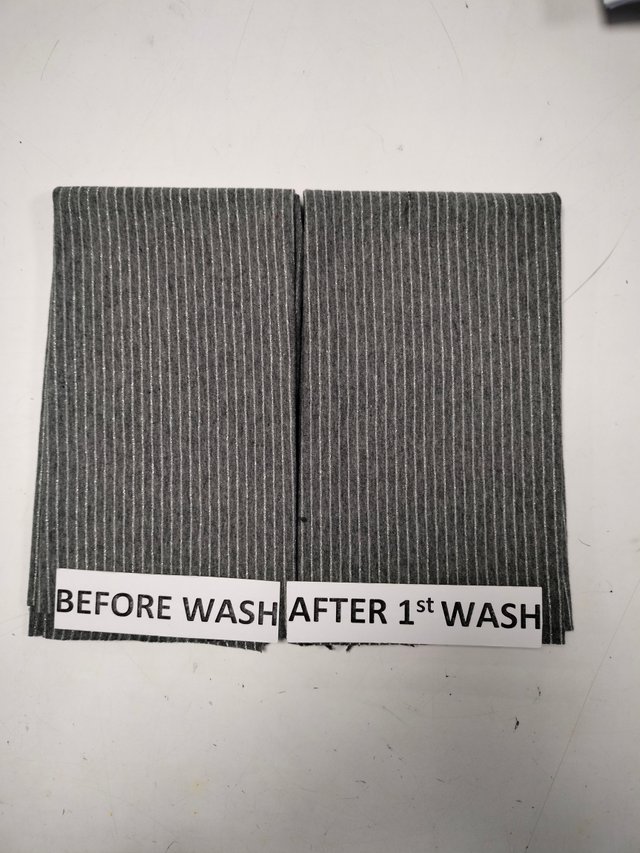

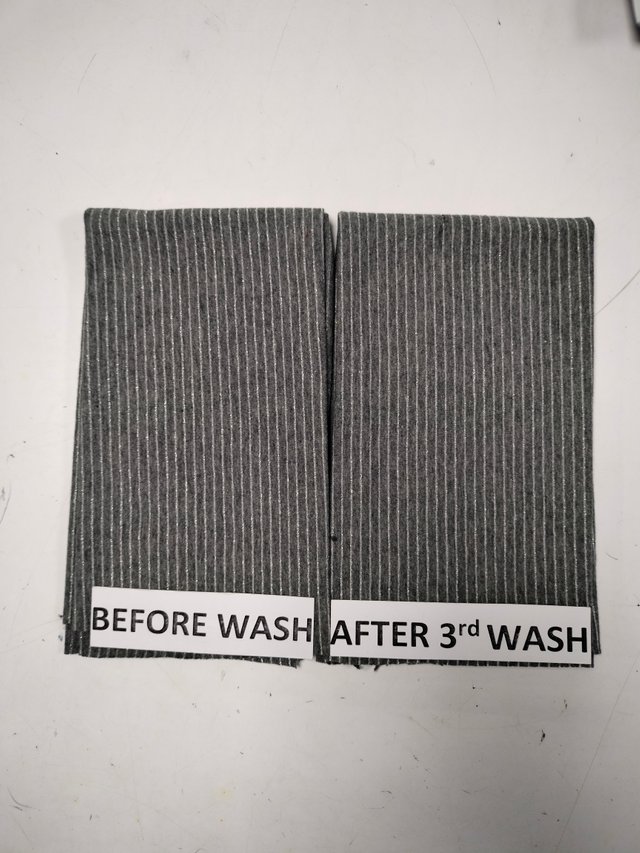

The garment you see here is your password. And another sample we washed was the first wash. 30 rpm for 40 minutes. It will be washed for about 30 minutes. And after washing it we will dry it with oven dryer then we will keep it for 30 minutes. That means our temperature is 21 degree and relative humidity will be 67%. At this temperature, we will keep the fabric flat for 30 minutes. Then we will measure it. This is our first wash result.

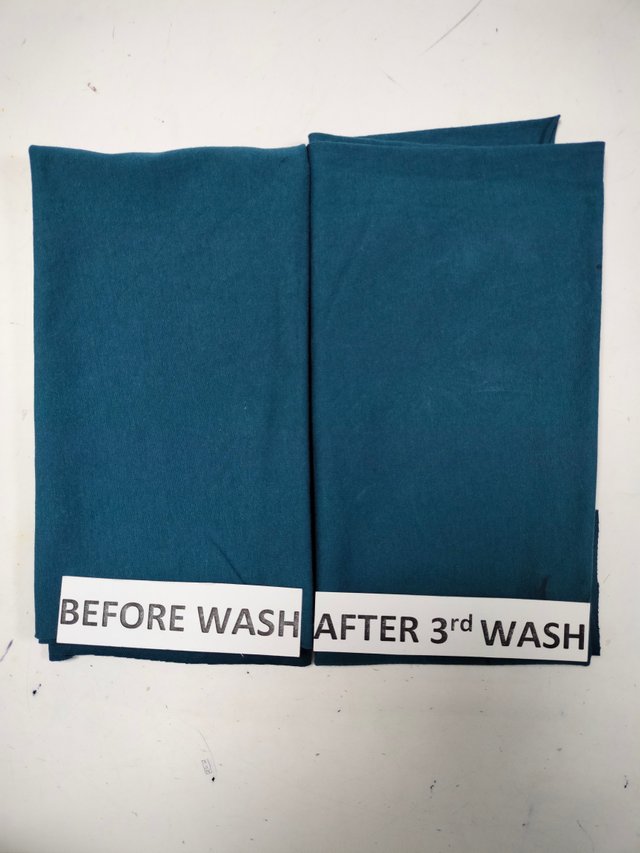

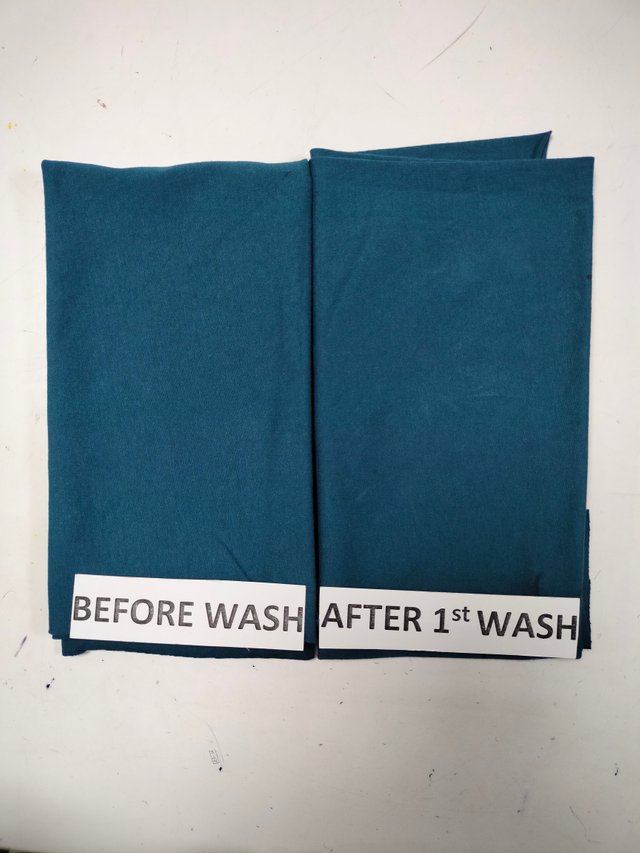

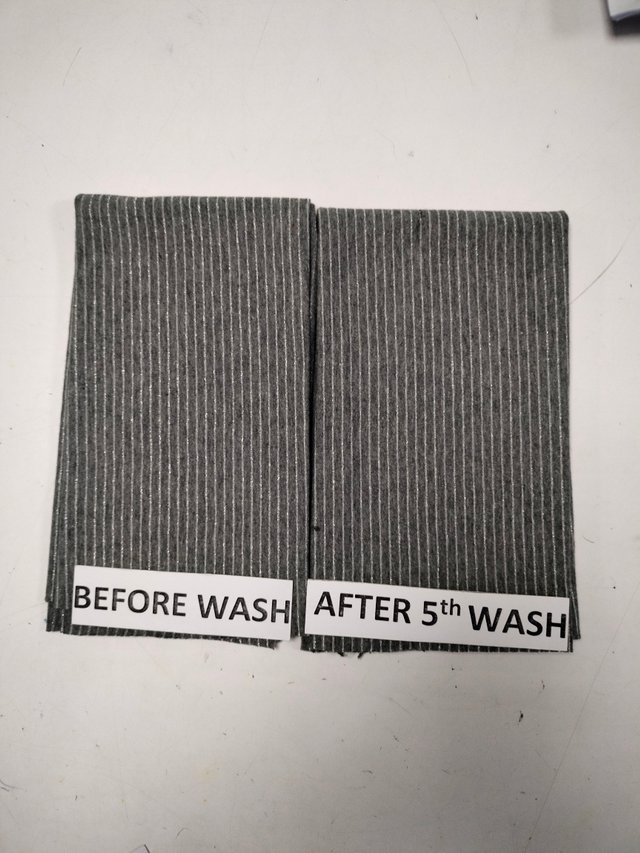

Then again we sew the fabric again after taking the measurement in the same process we will wash it again for the third wash. The feeding show will have the same temperature and the same RPM and we will treat for the same amount of time. After checking, we will dry the garment again after drying it in the oven. This measure is considered as the third wash measurement. And after Thadwas measurement you can see in the image above this garment there are two samples placed there one is failure and the other is state sample. So you can see in the comments what kind of change in appearance you see inside it.

So after these six years when we have measured it then we will come back to the same process and after the fitwash we will bring the garment to our laboratory. And that we again at 21 degrees Celsius temperature and 67% relative humidity. I will relax for about 30 minutes. Then we will re-measure that fabric and we will average the three results we got from the fast wars third wash. After averaging our Everest value is plus minus five. So in that case we will consider whether it will actually be approved by the buyer or not. If our average value is plus five or -5, we will not accept it, but it must be relatively less than plus five or -5. This is what we consider the case of Shinkes. Then, if that fabric is our brush, then we see the appearance of the brush, often filling formation. Fazil formation or matting formation can be these things we have to check the like box during our appearance.

I have only one request to all of you as to how a garment or a fabric should be valued in a testing laboratory. Compared to that, the price of a fabric can be much more, although we do not get such quality full garments or fabric in Bangladesh. Still, those who get a quality full garment or fabric are from reputed brands. Middlemen like us cannot afford to buy such branded goods. However, how a fabric is tested is up to you. If you want to know anything, you can contact me and tell me in the comments. Inshallah, I will try to tell you, since I have been working in textile testing laboratory for a long time. As much as I have experience I will share in front of you, inshallah everyone will be fine.

#

**THANKS ALL**

Upvoted. Thank You for sending some of your rewards to @null. It will make Steem stronger.

Hi, Greetings, Good to see you Here:)