ALL ABOUT MY JOB (ELECTROPLATING)

Hi to all stemians and have a good day. Today Im going to introduce my job to you. Im an electroplating section head since 2006. I've been in this field for 15 years already. This work is just hard to imagine but in reality its just really light and easy.

Electroplating is a process which a metallic is coated with one or more thin layers of some other metal such as copper, nickel and silver. It is the applications of metallic coating by means of an electrochemical process. Electrochemical because it is concerned with electrical energy and chemical energy.

CHEMICAL PREPARATIONS AND OPERATING CONDITIONS.

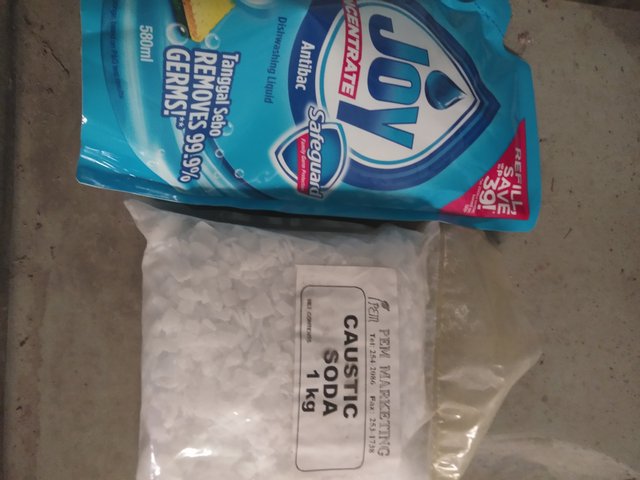

ALKALINE SOAK CLEANING

I mixed 10 kilos of caustic soda/sodium hydroxide and 1 liter of diswashing liquid to the container which 200 liters of distilled water.

Temperature --- room temperature

Dipping time --- 10 minutes

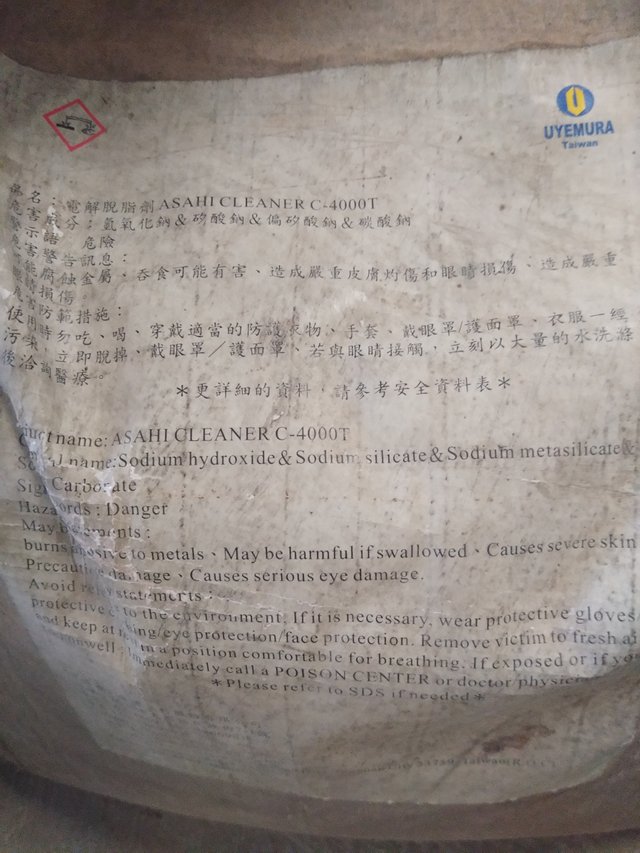

ELECTROLYTIC ALKALINE CLEANER

I dissolved 10 kilos of asahi cleaner c-4000t which contains of sodium hydroxide, sodium silicate, sodium metasilicate, and sodium carbonate to a 200 liters of distilled water in container and heat to 50 degrees celcius

Temperature --- 40 to 50 degrees celcius

Dipping time --- 3 minutes

Anodes --- stainless steel

Current density --- 8 ampere/decimeter

squared.

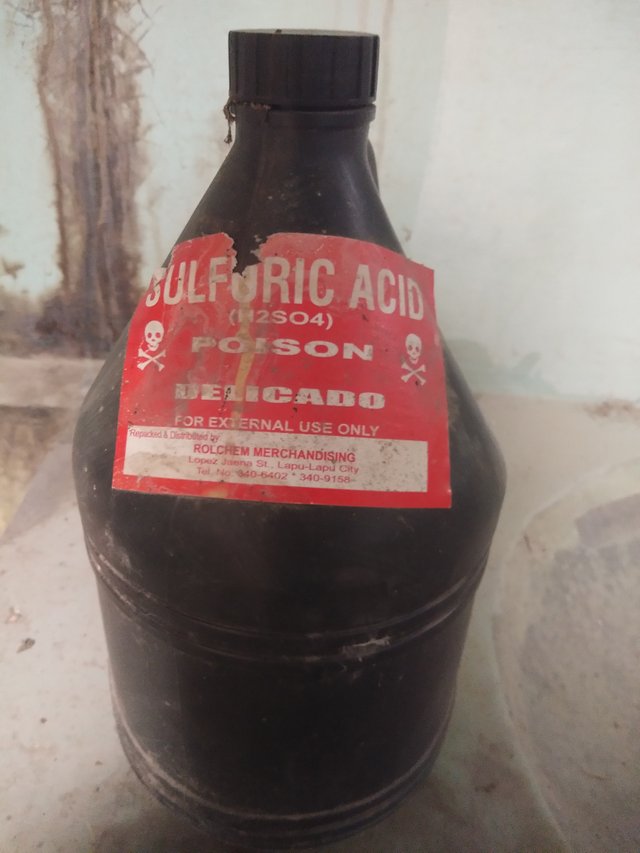

ACID DIP

I put 10 liters of sulfuric acid to a container with 200 liters of distilled water.

Temperature --- room temperature

Dipping time --- 10 to 30 seconds

NICKEL PLATING BATH PREPARATIONS

I filled the tank with 150 liters of distilled water and heat to 60 degree celcius. Then I add 8 kilos of boric acid, agitate to dissolve.

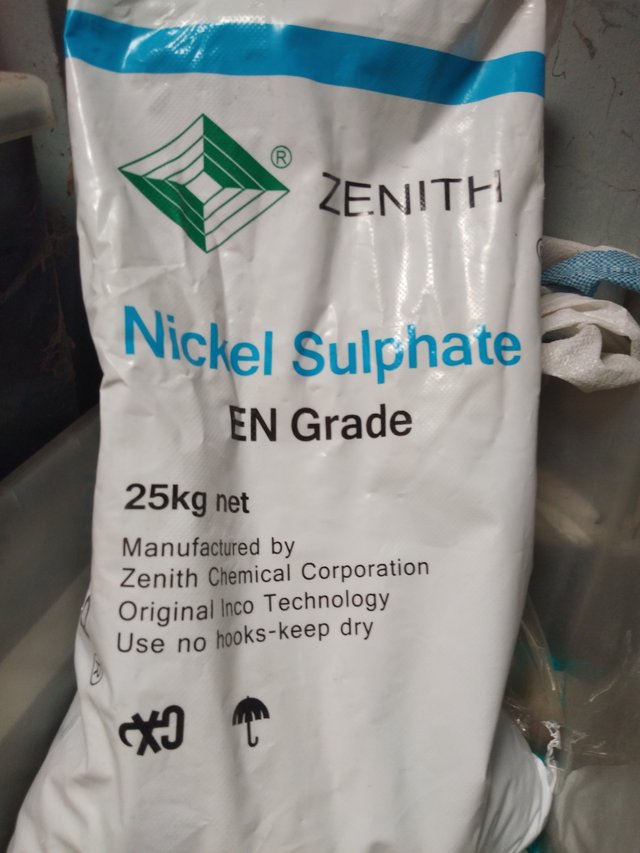

And I add 56 kilos of nickel sulphate

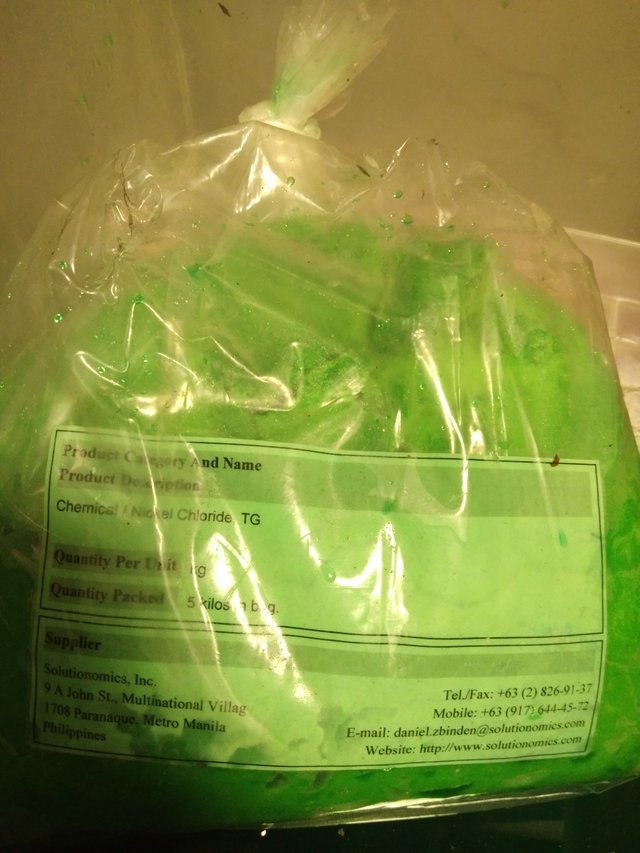

then 8 kilos of nickel chloride and dissolved.

After that I put an activated carbon to treat the solutions and agitate for 4 hours.

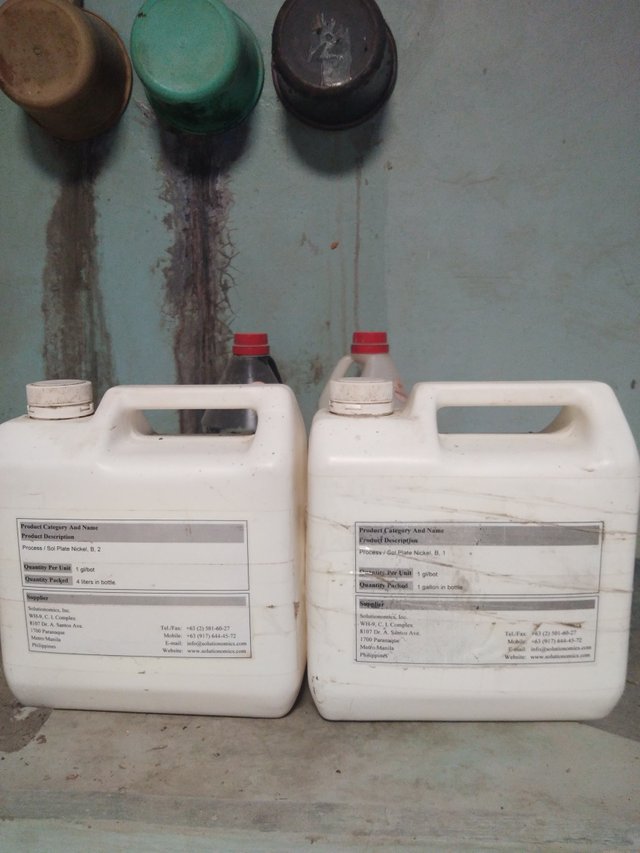

After treating the solutions I put into the plating tank, and add the 5 liters of brightener A and 400 ml of brightener B and adjust the volume and ph of the solutions.

Perform weak electrolysis about 1/2 ampere/decimeter squared for 30 to 40 minutes until completely covered.

OPERATING CONDITIONS

Current density --- 4 ampere/decimeter

squared

Temperature --- 55 degrees celcius

Voltage ---- 6-12 volts

Ph --- 5

Dipping time --- 15 minutes

Anodes --- nickel balls

And about the concentration of silver solutions, I dont know how to prepare silver strike and silver plate solution because the company just bought it.

Silver stike and silver plate operating conditions

Current density --- 0.5 ampere/decimeter squared

Dipping time --- 25 seconds

Temperature --- room temperature

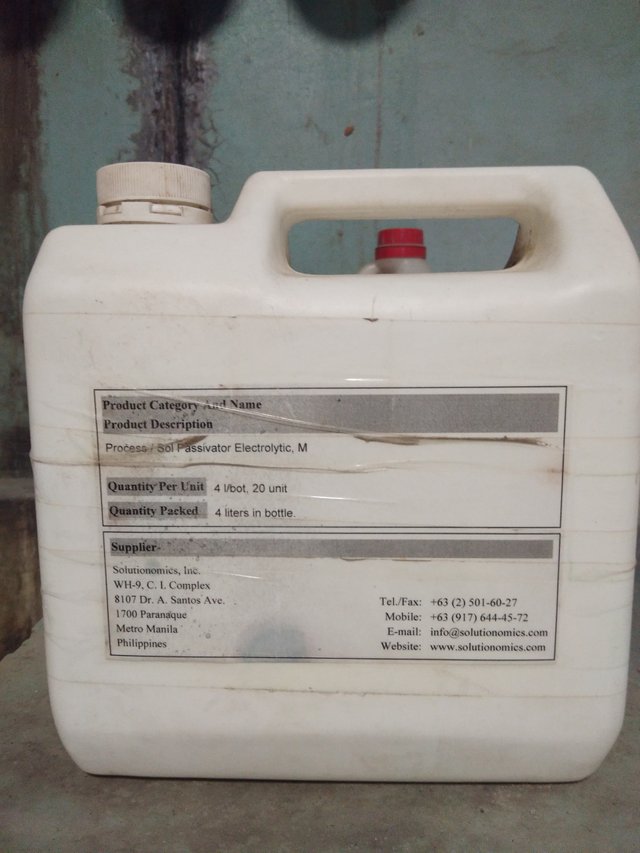

SEALER CHROMATE

I mixed 16 liters of silver anti tarnish to a 100 liters of distilled water

Current density --- 1 ampere/decimeter squared

Temperature --- room temperature

Dipping time --- 25 seconds

CHEMICAL COSTING IN BATH TANKS

ALKALINE cleaner

distilled water 200 liters =150 pesos

Caustic soda/sodium hydroxide 10 kilos= 950 pesos

Diswashing liquid 1 liter =120pesos

ELECTROLYTIC cleaner

Distilled water 200 liters =150pesos

Asahi cleaner c-4000t 10 kilos= 2800pesos

Stainless steel grade 316=6400pesos

NICKEL PLATING

Distilled water 200 liters=150pesos

Nickel sulphate 56 kilos=23240pesos

Nickel chloride 8 kilos=3920pesos

Boric acid 8 kilos= 720pesos

Brightener A 5 liters =1250pesos

Brightener B 400 ml= 200pesos

Anti pitting compound 400 ml=180pesos

Nickel anode 40 kilos = 750pesos

SILVER PLATING TANKS

SILVER STRIKE

distilled water 60 liters =45pesos

Silver strike solution 60 liters=26400pesos

Stainless steel grade 316=6400pesos

SILVER PLATE

distilled water 60 liters=45pesos

Silver plate solution 60 liters=78000pesos

Silver brightener part A 1200ml=5400pesos

Silver brightener part B 120ml=660pesos

Stainless steel grade 316=6400pesos

SEALER CHROMATE

distilled water 60 liters=45pesos

Silver anti tarnish 60 liters=17400pesos

Stainless steel grade 316 = 6400pesos

Drag out --- distilled water 500 liters = 475pesos

Rinse water --- distilled water 2500 liters= 1900pesos

TOTAL COST = 182,200 pesos more or less price may varies.

If you like the electroplating business you already have an idea. I hope this small contribution on this platform will help you.

Thank you for dropping by and God blessed!

Informative post @marlon. Keep it up.

Hahhhaa dili kha ta kasab-an ani.?

Ok rani @marlon82