3D Printer Speed Breakthrough Powers Technology Use Case

https://www.clickondetroit.com/all-about-ann-arbor/2022/05/23/university-of-michigan-de velops-technology-that-doubles-speed-of-3d-printing/

https://bitfab.io/blog/3d-printing-problems/

https://www.techbriefs.com/component/content/article/tb/tv/31814

Pixabay

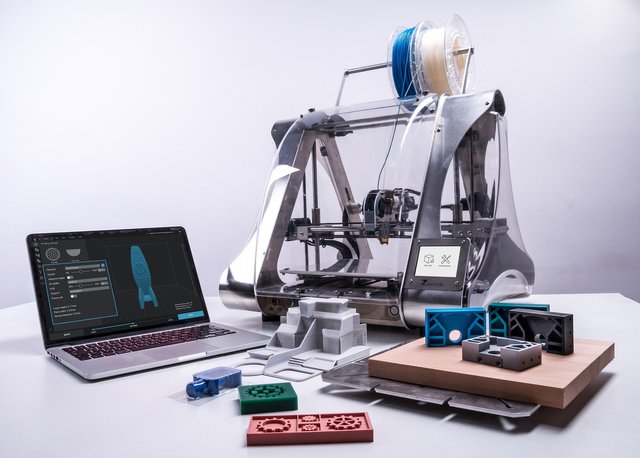

A universal problem with current 3D printing technology is it's speed. The header of the printer will often times vibrate during production if it goes too fast, creating uneven surfaces and errors in production. Manufacturers use 3D printers to create engineering models and shop-aides that help produce parts as a stand-in for fixtures to hold a part in place.

A major mistake rookie users of 3D printers make is to print too fast. It is generally recommended to print at 40-60 mm/s to avoid vibration problems that lead to overheating of the head and deformation of the product through various mechanisms. Industrial 3D printers can often go faster, but the issue of head vibration remains a threat to production. If a 3D printer operates too fast, uneven layering can occur that causes a model to break apart or deform so it is useless in a custom application. It was once accepted that this was a slow technology, and that many problems would arise from moving too quickly, head clogs and base temperature errors, but the University of Michigan's new software program has made a leap ahead to solving this issue.

The University of Michigan fix effectively doubles the speed of 3D printing, and thus bolsters the use case for 3D printers in research and industry. Even novices and hobbyists can appreciate a faster print. I have seen 3D printed technology in action in the aerospace industry, and know they will most certainly appreciate this recent development. The application was developed by Ulendo, and is called Filtered B Splines or FBS. The solution is a software package that modifies how the head of the 3D printer moves to maximize efficiency. Using software to solve hardware issues can be risky, but in this case, the solution appears robust. The software impacts how the 3D printer's head moves to create shapes.

As a worker in the fast-paced world of manufacturing, this development will be a game changer. Current times for creating prototypes and shop-aides will be reduced. With this technology, we can create faster prototypes and make a use case for more 3D printer usage onsite. It may be the use case I need to get a CreatBot F1000 with specifications here: https://3dprintersdepot.com/products/creatbot-f1000-industrial-affordable-reliable-large-scale-professional-3d-printer?currency=USD&utm_medium=cpc&utm_source=google&utm_campaign=Google%20Shopping. One can only wish.

Poster in Hive, Blurt and Steemit