Casting Moltan Metal, The Process of Lost Wax Casting.

In the years of 2007 and 2008 I was working in a professional bronze casting art foundry. I found meny photos and thought it would be a great oppertunity to explain and show the process of lost wax casting on a large industrial scale. First a silacone

rubber was put over a clay sculpture. Great care was taken not ruin any fine detail of the sculpture in clay. Then after the rubber mold has dried someone makes a plaster mold for reinfocing and stabalize the rubber mold inside. This can be done with mesh or straw and normal plaster.

From That mold, large wax castings can be drawn out in multiples by useing wax built up at around the inside of mold. The next step is to create a down shoot for the pattern to attach too and not take the full poor of metal.

It will look like this. it will have a cup to poor into.

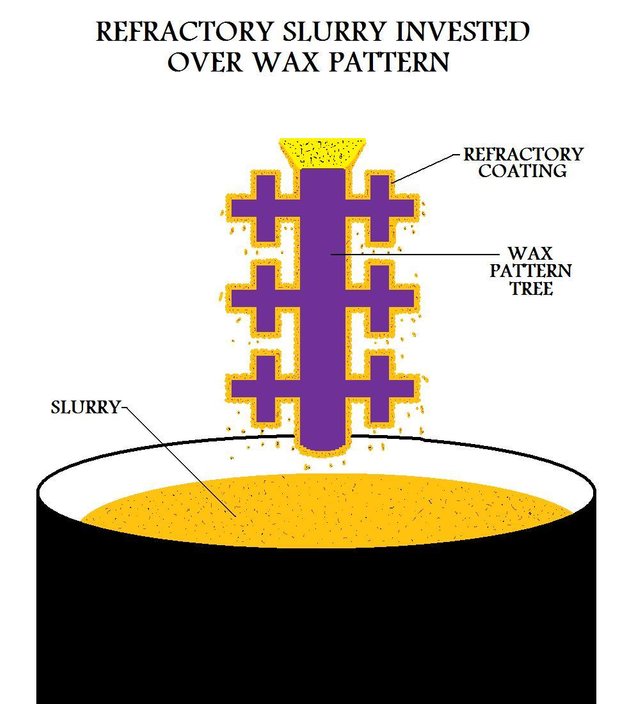

Then from this point you can create a ceramic shell from a slurry glue and ceramic sand granduals.

The diagram can show the process of creating a shell. several layers will need to built up your ceramic shell. Then from there you can cut the tops from the ceramic shell and place them carfully in a blast furnass. The wax will melt, pour out, and you will be left with your empty shell.

Then when your pouring metal is up to a liquid tempiture ( 2200°F ) for bronze.

After pouring the metal in and letting it cool into a solid. Then the ceramic shell can be broke away and you are left with your metal cast pieces. These are some pictures of peices of the four bronze dragons that are now in china-town of Philadelphia. PA

After the segmants are fully welded together and the pattern of the surface are astheticly matched, The surface is heated and chemicals are added to change the color of the metal. This is called a patina.

Here are some pictures of the finnished casted dragons with a blue-green patina. You can see these amazing sculptures in China-town Philadelphia PA.

@stray,

Wow that would be awesome! Thanks for sharing such great professional experiences with us.

Cheers~

WOW - what cool process...

love the Step by Step explanation -

Well done and a great dragon :-)

very cool! Resteemed

@originalworks

And when the say lost wax, the really mean lost wax.

The wax isn't melted out, its vaporized.

But still you get a pile of sludge wax after the molds were in the kiln

Wow.. fantastic.. Thanks for the sharing this rare article.. Very creative..

Upvoted and resteemed..

This is one of the best articles I have seen / read today!

Upvoted ! ! !

Amazing! Very impressed ...

That is pretty cool!

Wow that is awesome..

I'm really like your work...

Thank you so much @stray sharing your life expereice with us..

Wel done and safety frist my friend..

Cheers!..

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by seanbob/spbesner from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, and someguy123. The goal is to help Steemit grow by supporting Minnows and creating a social network. Please find us in the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you like what we're doing please upvote this comment so we can continue to build the community account that's supporting all members.