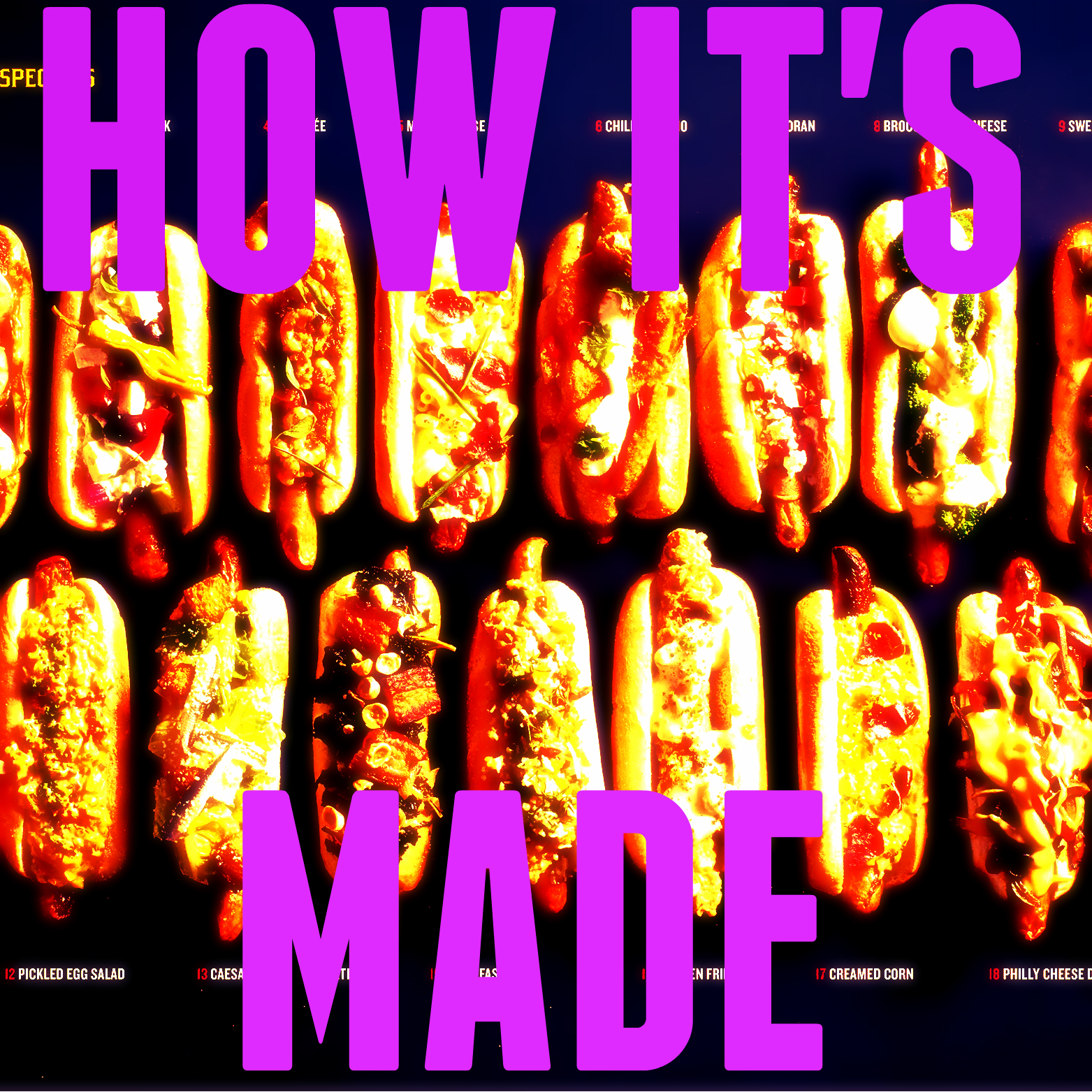

How It's Made: Hot Dogs

Hot Dogs.

Who doesn't love a cheesy hotdog with ketchup and mustard? A favorite past-time snack for many of us, hotdogs made their way into the lives of many at a young age. Coming in endless flavours, styles and textures, you can do anything with a hot dot!

What is it?

A hot dog (also spelled hotdog), or frankfurter, frank, or wiener, is a cooked sausage, traditionally grilled or steamed and served in a partially sliced bun. Typical garnishes include mustard, ketchup, onions, mayonnaise, relish, coleslaw, cheese, chili, olives, and sauerkraut. Hot dog variants include the corn dog and pig in a blanket. The hot dog's cultural traditions include the Nathan's Hot Dog Eating Contest and the Oscar Mayer Wienermobile. This type of sausage was culturally imported from Germany and popularized in the United States, where it became a working-class street food sold at hot dog stands and carts.

How It's Made...

- Special selected trimmings are cut and ground into small pieces and put into the mixer. Formulas are continuously weighed to assure proper balance of all ingredients

- A high-speed, stainless steel chopper blends meat, spices and curing ingredients into an emulsion or batter.

- The emulsion is pumped and fed into a stuffer. Shirred strands of cellulose casings are mechanically positioned on the stuffing horn. As the emulsion flows through the horn into the casing, the filled strands are linked into hot dogs of exact size. The strand is then put on the smokehouse conveyor system.

- In smokehouses, under controlled temperature and humidity, the hot dog is fully cooked and hard-wood smoked for texture, color and a delicious flavor.

- After passing through the smoke and cook cycle, and being showered in cool water, the hot dog goes into the peeler. Here the protective, air and smoke-permeable cellulose casing "skin" is stripped away and individual links are conveyed to the packaging line.

- Finally, the hot dog is conveyed to scales which divert off-weight franks, and is then fed into the vacuum packaging equipment. Here, individual packages of exact number and precise weight are wrapped and vacuum sealed in plastic film to protect the freshness and flavor of the hot dog.

- Once packaged and boxed, hot dogs are moved to storage coolers and loaded on refrigerated trucks for delivery. The entire process, from cut trimmings to the consumer's table is often measured in a matter of hours. From beginning to end, the hot dog is carefully inspected by federal officials according to strict federal standards of quality and sanitation.

Conclusion

Although I don't eat many hot dogs anymore, I do appreciate the work put into making a good one. It's always interesting to delve into what's involved in making something, it really hits a spot for my OCD need of having to know how something is made. Thanks for reading, if you got this far, please Upvote, Follow and Resteem!

Great topic