Concrete and how it works! [Engineering 101]

What is Concrete? (the short version)

Seriously, who created this liquid that turns into a solid over time? Witches and wizards?

Nope! Its the science of chemistry!

In everyday use, concrete refers to a cement binder with an aggregate, such as stone, to create a solid mass in the shape in which it is poured. Black top asphalt seen on roads and highways are also a type of concrete that's referred to as "asphaltic concrete". You can call almost anything a concrete if it satisfies the basic description. In this article, we're going to focus on cementitious concrete, which uses Portland cement as the binder, stones as the aggregate, and water to start the chemical reaction to solidify it.

Major Concept 1: Concrete is strong in compression, weak in tension

Concrete is not very good at resisting tension forces. If you installed a bolt at each end of a rod and pulled on it, the concrete would fail at a relatively low stress point. In order to counteract those forces, we need to find ways to increase concrete's tension capacity. Before we go on, we're going to go off on what seems like a tangent but bare with me here.

We need an analogy to understand how the forces get distributed inside concrete elements.

Imagine you are holding a weight and you begin to contort your body in different positions. You'll realize that your muscles have to continuously contract and relax at different times and at different levels of effort to maintain balance.

Now, consider all of the actions that your muscles have to perform throughout your day. When you pick up a burger to eat, your bicep is pulling your forearm. When you stand up, your front quad is pulling your hip to align with your shin bone. When you make a fist, the flexor muscles on the inside of your forearm are pulling your fingers closed.

These "pulling" forces causes the muscle to behave in a way engineers call "acting in tension", which is another way of saying that the muscle is able to pull things.

Your bones on the other hand, counteract the forces created by the muscles because for every action, there is an equal and opposite reaction (newton's 3rd law of motion). If your muscles pull, your bones must push (or act in compression), otherwise you are not getting up, you are not eating that burger, and you won't be able to grab your cell phone and text away.

Using this analogy, the concrete would be the bone, which means that a tension element is necessary to balance the forces. This commonly comes in the form of steel reinforcement bars but can be done in other ways that we'll look at later.

A structure experiences a variety of loadings

Concrete structures experience a variety of loads throughout the day much like your body. In the morning, people leave their homes and commute to work, applying hundreds of thousands of pounds of car and body weight onto bridges, buildings and more. The late morning heat from the sun causes one side of the structure to expand more than the shaded side. The afternoon bakes the whole building as the inside is air conditioned and cool. The evening wind causes a structure to flex from side to side.

All of these motions cause various parts of a concrete structure to undergo a variety of pushing and pulling, so some steel bars are not always engaged.

Example of reinforced concrete behavior

By adding steel reinforcement in specific locations, engineers can also create structures that would be beyond impossible with concrete alone. Take for example, the photo below, which employs something called a cantilever in order to be self supporting. Hidden inside the casting of concrete are steel bars that are acting in the tension, while the concrete is being compressed.

I've drawn a diagram to show the pulling and the pushing forces to help visualize this.

Major Concept #2: Concrete protects steel reinforcement using mass and chemistry

The steel bars are most often encased into concrete to protect the steel from the atmospheric environment. Our air can corrode steel if the conditions are humid and acidic. If the steel is exposed to this type of environment for a long enough time, then it will corrode away into dust after a long enough time.

On the other hand, if the steel is embedded into concrete properly, then the mass of concrete alone can be sufficient to prevent corrosion. The more corrosive the environment, the deeper you want to embed your steel. The typical values are anywhere from 3/4in to 3in for buildings and 1 1/2in to 4in for bridges.

The key take away here is simply that reinforced concrete structures with exposed steel reinforcement have their last days written in stone unless they hire the right engineer to assess and fix the problem early on.

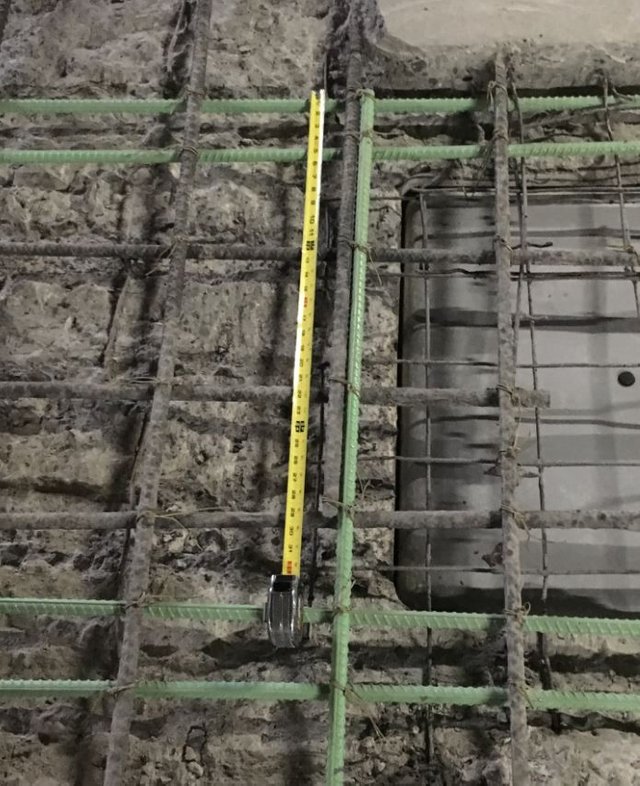

Let's look at some example of photos of concrete cover

In this first photo, we are looking at several pieces of reinforcement bars. Notice the cover that has been provided to protect the rebar. In this photo, there's approximately 1 1/2" of concrete cover, yet the bar is still rusting and you can clearly see cracks develop as a result. It just so happens that this is a parking garage and the cars bring in salted water from driving in the winter snow. The salts slowly penetrate the concrete via gravity and eventually attack the rebar. In this case there is insufficient cover AND a chemical attack occuring. The only resolution in this is to provide a barrier to prevent the migration of the salt water.

In this photo, we see a black coating on top of the concrete floor. This coating acts as a impermeable barrier to prevent chemicals from leeching into the concrete.

Alternatively, we can also apply a coating directly onto the bar that performs the same function. This particular application uses a product called Sika Armatec Epocem, or Epoxy Cement.

I really like both options, but the barrier application is far cheaper, however its often necessary since chemical attacks on slabs are not very common unless its a parking lot.

If you like engineering tech articles, please upvote and leave a comment below! If there's anything you want me to talk about, please leave a suggestion below too!

ENGINEERS AND ARCHITECTS ROLL CALL!!

I've been trying to get this list going ,but with the 50K active users here and most of them not in the field of engineering, this list is painfully slow to grow. BUT if you want to be part of the list, post up below with the following code and add your self!

| # | User | Profession | Education | Country |

|---|---|---|---|---|

| 1 | @motoengineer | Structural Engineer | City College of New York, BE | USA |

| 2 | @katayah | Architect | Warsaw University of Technology & Riga Technical University, MSc of Arch | PL |

| 3 | @gregjava | - | Enugu State University of Science and Technology; Delta State University | NG |

#| User| Profession | Education|Country

--- | --- | --- | --- |---

1| @motoengineer| Structural Engineer| City College of New York, BE|USA

2| @katayah| Architect| Warsaw University of Technology & Riga Technical University, MSc of Arch|PL

3| @gregjava| -| Enugu State University of Science and Technology; Delta State University|NG

There is a mistake in the diagram for the cantilever. If anyone can point it out, you win a 100%upvote!

My parents have a concrete house that was made in 1909. They did a major renovation a few years ago and found out what happens to concrete that has been one block from the ocean for 100 years.

It was a big deal! I will have to tell you the story some time. Maybe I can get Dad to send me some of his pictures.

send that photo over, im SUPER interested in seeing construction last 100 years. Most of what I uncover in NY is over 100 years old, so I have a great collection as well as knowledge of restoration on these structures!

Here is the whole story:

https://steemit.com/diy/@professorbromide/restoring-a-100-year-old-concrete-beach-house

This post is very concrete

Ahahahaha good one

You have a minor misspelling in the following sentence:

It should be occurring instead of occuring.All I can say is that I'm very excited to see your username @motoengineer. Aftet long time I saw a engineering post here on steemit. My friends use to tell me about their interview questions like what is cement,how to determine sand strength,soil strength bla bla....but now when I think about them it feels so great. That is neat and pretty good explanation with cool examples 😀😀.

If my engineering professors were like you then I would have got more interest in engineering.

There is lot of interesting technical stuff to talk about on steemit. But most of the people run after crypto. Don't know why...

Thanks for the comment!

Most professors are cut and dry. It isnt a professor issue though. Most engineers are also cut and dry which makes it difficult to learn engineering.

As for why people talk more about crypto than anything else is simply because thats the rage right now. The focus is on the next tech boom, and that tech will be crypto.

Right!!

You seem to be a technology enthusiast. I worked for our formulastudent car during my graduation. That gave me a push to continue engineering. Today here I'm in one of the top automotive companies of world. But still I'm not able to concentrate. Very Weavery mind.

You seem to be writing lot of technical stuff...I have to check out some of your articles.

This post has been voted on by the steemstem curation team and voting trail.

There is more to SteemSTEM than just writing posts, check here for some more tips on being a community member. You can also join our discord here to get to know the rest of the community!

Too complicated to understand, I had to reread to understand, but in vain because the knowledge I had was not worth your concrete.

By the I am your follower from now