Tubless tyres or Radial Tyre ( Best Choice)

Image source: Google

I keep thinking always when I hear tubeless tyre, my thought is where does the air stay and how does it work but now I think I have a bright idea now.

Design of vehicle wheels has undergone so many improvements from the beginning when wooden wheels to `mummified' wheels to the modern pneumatic wheels.

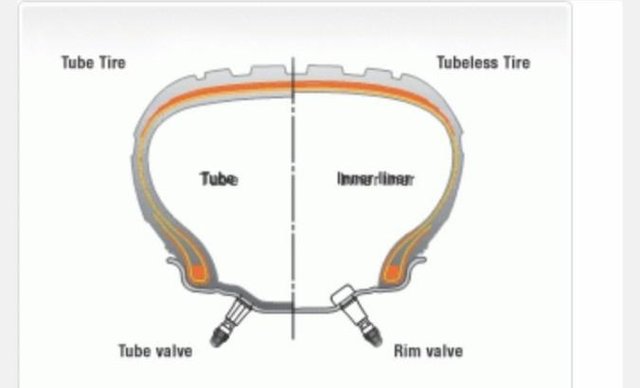

Talking about the pneumatic wheels, they have evolved over time; the conventional wheel consists of a steel drum fitted with a rubber tube enclosed in a tyre made up of several plies of rubber with strengthening reinforcement materials like nylon and steel.

The tube is a hollow to radial rubber enclosure filled with air to the mass of the vehicle riding on the particular wheel. The air is filled into the through a self-sealing nozzle also known as valve. With time the air is released slowly due to prolonged usage through the tube, in addition to leakage of the valve of the nozzle; when it gets to this stage the tyre requires refill to a particular pressure depending on the vehicle specifications.

Tubeless tyres are the same with the tubetype tyres by which the job or fuction of a tube is replaced by a non-permeable inner surface of the particular tyre itself. This Non-permeability inner surface is achieved through halobutyl compound in the layer inside of the tyre (inner layer of the tyre).

Halobutyl rubbers are impermeable. Structurally, the rim-holding part (known as bead) has an estra compound with definite profile that helps flush the air against the rim. moreso, it has definite bead profile, else it will aid an escape for the air contained.

The inner part of the tyre in a conventional tyre which is of smooth rubber and it is designed for friction reduction between the tube and tyre to prevent wear and tear when running .

Image source: Google

We all know how usefulness of tyres, they are for running automobiles perfectly on roads. In the old, tyres were manufactured with a provision of an inner tube that was filled with air to provide a soft cushioning that made vehicles running perfectly. Tube are placed in the inner part of the tyre and then air will be filled through a small nozzle that has a valve which kept the air pressure ideal to bear the mass or weight or load of the vehicle.

If a sharp object should pierce the tyre like a nail or spike as the case may be, the tube will be punctured and cause loss of air then the tube will need to be patched or replaced.

In this modern day the manufacturers of tubeless tyres are here to solve that problem. Radial tyres are invented to places steel linings in a tyre to make it better than the regular butyl rubber tyres. people do not have the ideal of the differences between tubeless tyres and radial tyres.

Those individuals that always check their air pressure in the tubes of their automobiles are almost free from subsequent piercing of their tubes as little sharp objects would never get a chance to pierce through tyre and tube if the air pressure is accurate as specified by the vehicle manual. Most people don’t go through this process of checking the air pressure and can causes them inconvenience in the form of punctures of tyres.

Tubeless tyres are designed in such a way that the tyre functions like a tube. The plies of the tyre are practically the same regardless of the type either it is tubeless or radial tyre, but what makes a tubeless tyre exceptional is that it has an inner lining layer that is made up of halogen butyl rubber such as bromobutyl rubber or chlorobutyl .

This rubber has a special property whereby it can seal any small puncture caused by any sharp object or a small nail as the case may be. This means that even if there is any mishap with a nail and a small puncture is caused by it, the tyre seals the leakage itself by closing the leakage and the vehicle can cover distances up to 200 km without having to stop or getting the assistance of a mechanic to get the tyre repaired.

This type of tyres make use of belts which are made of steel that work as stabilizers directly under the tread. This system protects the treads made on the tyre that is for better gripping of roads. Thus it ensures longer tread life, a smoother steering control and resistance to rolling. Moreso, some individuals feel that radial tyres do not provide a smooth run when the car is running at slow speeds on rough roads giving a feeling of harder ride.

• Tubeless tyres can keep running the vehicle even if there is a small puncture.

• Radial tyres are preferred choice of millions as they increase the life of the treads on tyres using steel belts beneath the treads. On the other hand tubeless tyres are a recent innovation adding a layer of halogen butyl rubber lining inside the tyre obliterating the need of a separate tube.

PS: The plies of the tyre are similar, i.e. cross ply or radial ply depending on the PARTICULAR type of tyre. But the inner lining layer is made up of halogen-butyl rubber like bromobutyl rubber or chlorobutyl rubber. In a situation where by the puncture is impromptu by a sharp object, the tyre improves air retention by inhibiting air permeation. The nail fuctions as a plug and an enthalo-butyl rubber tyre has a slow leak rather than a sudden deflation.

When there is no internal tube-tyre structure, eliminates friction due to rubbing between the tube and the tyre; so it runs cooler compared to the tube type tyre.

And finally Another major design consideration difference comes from the consideration of the stability and effectiveness of the tyre in the rim of the wheel drum.The conventional tyres have a rigid bead heel and in a case where by the tyre is tubeless the bead heal is provided with an extra wrapping that ensures better and tight fitting to the rim. This gives better cornering ability to the tubeless tyre. A tubeless tyre is lighter and so creates less vibration. The sidewall of the tubeless tyre is suppler as there is no internal structure as in the case of the tube type tyres and this lowers the rolling resistance during running.

Reference

UPVOTE, COMMENT AND FOLLOW @MITTYMARTZ

THANKS FOR READING

waoh, i really enjoyed reading the above post,am enlightened the more,thanks for posting it. I have been wondering why the big trucks mostly use tube tyres, is it because of the size of the loads they carry or because of the thickness of their tyres that may give them the feeling that small sharp objects are not likely to be ale to affect it. i will also like to know your view. am following you, you can do that for me too thanks

This post has received a 0.05 % upvote from @drotto thanks to: @banjo.

Nice1