New method to recycle plastic from carpet waste

Polypropylene is a polymer derived from petroleum widely used for the manufacture of carpets, a product for which there is currently no way to take advantage of its use as a decorative mat for our floors, so that once worn and discarded, they end up in landfills or being incinerated. But a new recycling method could make it possible to recover this material to be used as raw material for other products.

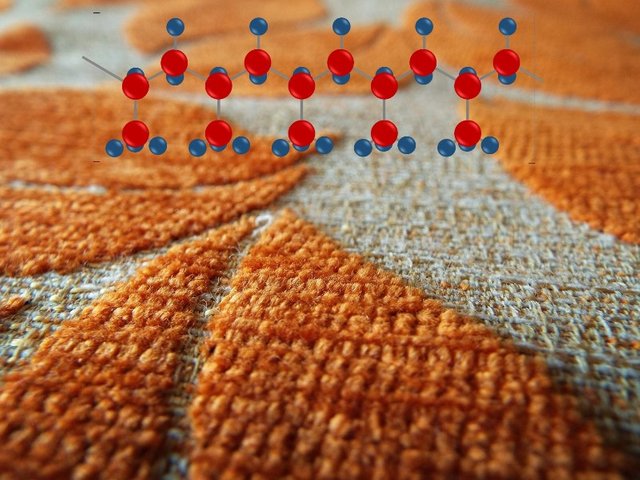

The carpets contain polypropylene, a widely used polymer. Source: edited image, original from pixabay.com.

The problem with carpet is that it is a product composed of several materials, natural and synthetic, including natural wool, polyester, nylon and polypropylene, which means that there is no efficient way of recovery, since the mechanical separation of the polypropylene from the rest of the carpet would be a nightmare, so there is no procedure for recycling this type of waste. On the other hand, carpet fibers are painted and treated with various additives, which reduces the quality of the polymer that can be recovered.

However, the newly developed method is based on a new ionic solvent that allows the recovery of polypropylene from carpet waste, without affecting the quality of the polypropylene. This is achieved because the solvent selectively extracts the polymer from the carpet fibers, eliminating colorants and other additives, producing a polypropylene with a quality similar to the newly manufactured one, allowing it to be used in the manufacture of other plastic products.

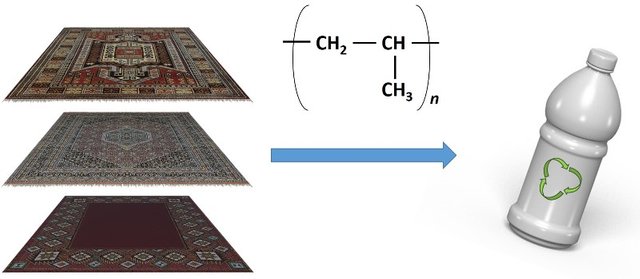

The new method makes it possible to recover this material for use in new products. Source: @emiliomoron, contains images from pixabay.com: carpets, bottle.

The process was developed by the Fraunhofer Institute for Building Physics (IBP) as part of the EU project called ISOPREP. According to published figures, around 1.6 million tons of carpet waste is produced annually in the EU alone, so we can see that a lot of this material is being wasted and will only end up polluting the soil or the air when incinerated.

Although carpet waste was the target of the research, the researchers do not rule out that the method has other applications and can be adapted for use in other waste streams containing polypropylene, something that is undoubtedly important for the scalability of the process.

However, the ecological aspects of the process still need to be studied, because although it is true that it allows the recovery of a very valuable compound from waste, it is necessary to establish very well what type of emissions this new method will generate and how much energy will be consumed by the recycling of the carpets, in order to guarantee that the greenhouse gas emission rate will be lower than making new polypropylene, and that the solvent loss rate will not incorporate a new negative impact on the environment.

Thanks for coming by to read friends, I hope you liked the information. See you next time.

It is important that this type of methods to recycle plastics is under study and in this way to be able to see the ecological impact aspects in the production process.

Greetings @emiliomoron and thank you for your contribution to this publication.

That's right my friend, it is necessary that it is well reviewed and studied before taking it to its industrial implementation, Greetings friend, and thanks to you for reading!

Hello @emiliomoron

I think it is a great step, as it allows recycling of something that is potentially harmful to the planet.

I didn't know it couldn't be recycled until now. What I hope is that it is not such a rabbit or expensive process, because often such expensive processes end up not being taken on by companies.

That's right my friend, it's a good idea to take advantage of something that is potentially harmful to the planet. Hopefully the process can be scalable and applicable on a large scale so that it can be implemented. Greetings my friend!

Hello @emiliomoron, This that you comment in your last paragraph is very important, it is necessary to verify that this "recovery treatment" represents the lowest "environmental cost", this is what would largely qualify it as an effective mechanism and run the risk of being discarded.

No doubt my friend @tocho2. It is important that the process represents a lower environmental cost than obtaining virgin polypropylene, we want to reduce the impact not add a new one.

This is a good initiative. I am reading this idea for the first time and being the fact that it is productive even with waste materials makes it sound more good.

Taking advantage of waste materials is always a good idea, let's hope that this type of initiative is replicated with other materials that do not have a way to use them after their initial purpose has been fulfilled.