Associated technology for the cleaning and transport of oil well cuttings and the calculation of their mass and volume

Technology is present in all aspects of our lives, engineering does not escape from this reality, for the case of petroleum engineering and the oil industry the technologies associated with the cleaning of the riprap (cuttings of the formation produced by the drill bit while drilling) are in constant evolution to improve the tools that are lowered into the well, since the more effective cleaning of the hole there is, the better the tools with cutting-edge technology lowered into the well will work.

Effective hole cleaning involves being aware that there is a volume of riprap to be received at surface, so making the correct calculations of the mass and volume of riprap to be received at surface will provide us with the most optimal way to apply the logistics plans for transporting the riprap to its final treatment destination.

The way this is related is that if we perform well the calculations of the volume of cuttings, we will be able to put together our logistic plan to transport cuttings at surface, without having to stop drilling the well, therefore the cleaning of cuttings in the hole will be efficient, taking care of the integrity of the tools such as drill pipe, drill bits, tools for measuring drilling parameters such as MWD and LWD, among others.

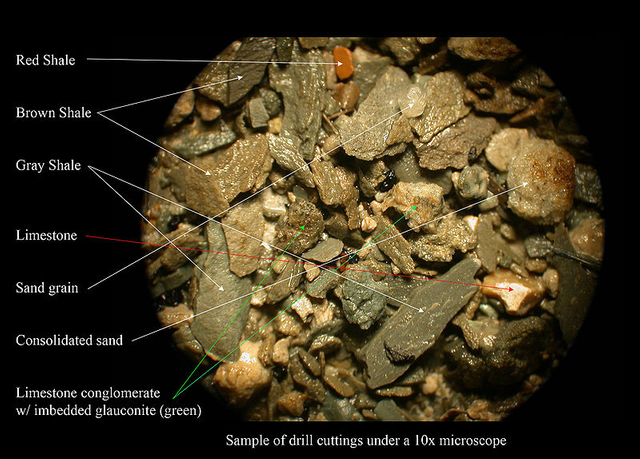

The cuttings generated during the drilling of an oil well, especially considering that when an oil well is drilled, the drill bit cuts the formation it goes through, these cuttings are called drilling cuttings.

Drilling cuttings are cleaned from the bottom of the well while drilling with the use of a drilling fluid, the drilling fluid must have a speed that is called optimal annular velocity, the speed of the drilling fluid must be sufficient to lift the cuttings from the bottom of the well to the surface where it will receive a treatment called solids control.

One of the main objectives of this publication is to make the relevant calculations of the amount of riprap volume that can be generated in the drilling of an oil well considering the depth of the well and the porosity of the drilled rock.

The importance of calculating the volume of riprap is that knowing its volume, we can estimate the logistical capacity that we can have on the surface to be able to receive all that volume of riprap that comes from the bottom of the well as a result of the drilling activity.

Example of a field exercise where we calculate the total mass of solids generated (riprap) in the drilling of a well.

Determine the mass and volume of solids generated (riprap) in pounds and barrels respectively generated in the drilling of 500 feet in a hole whose diameter is 12-1/4 inches, taking into account that the specific gravity of the riprap is 2.40 g/cm, and the porosity of the formation in those 500 feet is 20%.

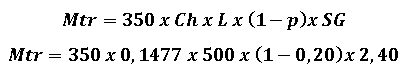

The following equation is used to calculate the total mass in pounds:

Mtr= Total mass of riprap measured in lbs.

Ch= Volumetric capacity of the pit measured in barrels / ft.

L = drilled length measured in feet

p = porosity measured as a fraction.

SG = specific gravity of the riprap.

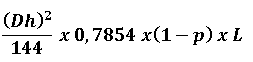

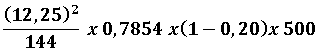

As can be seen in the above equation, it is necessary to calculate the volumetric capacity of the pit as follows:

Once the volumetric capacity of the hole is calculated, we substitute the length of the drilled section, which is 500 feet deep, the porosity in fraction (0.20) and the specific gravity of the riprap, which is 2.40 g/cm, as follows:

Mtr = 49627 Total pounds of drill cuttings mass.

In the exercise we are asked to calculate the mass in pounds, but if we want to express it in kilograms we would have to take into account that 1 Kg is equal to 2.20462 Lbs, we make the following conversion factor:

Mtr = 22510 Kilograms.

Knowing that we are going to have 22510 kilograms of riprap on the surface, allows us to know if the containers, transport and other accessories are capable of supporting this load, now if we want to know the volumetric capacity in getting the dump trucks that can move the riprap from the place where it is drilled to the destination where it can be treated from the environmental point of view, for this we calculate the volume of riprap as follows:

Volume of riprap (cubic feet) =

Volume of riprap (cubic feet) =

Volume of riprap (cubic feet) = 327,38 cubic feet of drill cuttings

If we take into account a unit of volume in the international system of measurement, we can convert the volume of 327.38 cubic feet to liters, knowing that 1 cubic foot is equal to 28.317 liters, the conversion factor would be made as follows:

Volume of debris measured in liters: 9270 Liters of drilling cuttings

If the equivalent of this volume of surface riprap is 9270 liters and we assume that the transport that will take it to its final treatment destination has a capacity of 3500 liters, how many trips does it have to make to transport this volume of drill cuttings?

Logically it has to make 3 trips, since if the first two trips are made to the maximum of its capacity, it could only transport 7000 liters of riprap, missing to make a third trip with a volume of 2270 liters of riprap.

Bibliography consulted and recommended

- Well Control Manual. Well Control School (WCS). Hearvey Louisiana. Year 2003

Note: The equations presented in this post were elaborated by the author, using the design and equation insertion tools of Microsoft Word.