The che-mistry of Cheese Making

I am sure, everybody ‘almost everybody’ on this planet has a thing for Cheese. The discovery of which, like most other wonderful innovations on this earth, was an accident or an act of negligence.

The story:

Once it so happened, in the fertile region of Middle east around 6,000 – 7,000 BC, a shepherd while travelling to nearby village halted for a while in a cave, the forgetful shepherd pursued his journey but left a container with goat’s milk in the cave. Upon his return journey when he halted in the same cave, he noticed that the milk had turned acidic and solidified into thick Yogurt, the Yogurt could be separated into solid curd and liquid whey.

A crazy discovery isn’t it, else how can you separate Milk from Water.

He further noticed that upon adding salt into the fresh curd could convert the curd into something that we call now as CHEESE 😊

The Chemical Process

The above story, thought factually correct, is good for a 5-year-old… But since it is very unlikely that a 5 year old would be reading this page, we will now explore the science or chemical process that led to this transformation of Milk to Yogurt to Curd to Cheese and variables that produces different varieties of cheese

Guiding principle

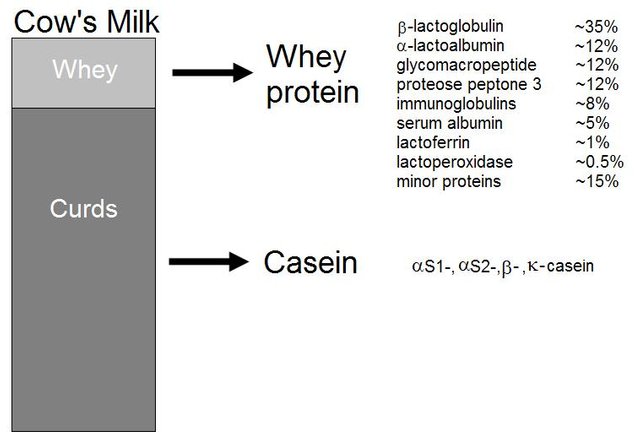

In Cheesemaking the milk protein (Casein) is retained by separating milk into solid curd and liquid whey. Solid curd is further salted and left to ripen in a controlled environment.

As in the above picture, the Whey component is drained out, while the Casein Proteins in Curd are further broken down and moulded into Cheese

Step 1 – Let nature do its job – The friendly ‘starter’ bacteria

Not all bacteria are bad for health. If left idle for sometime, the bacteria present in unpasteurized milk will start souring it converting lactose (milk sugar) into lactic acid. But this is not as simple as it sounds.

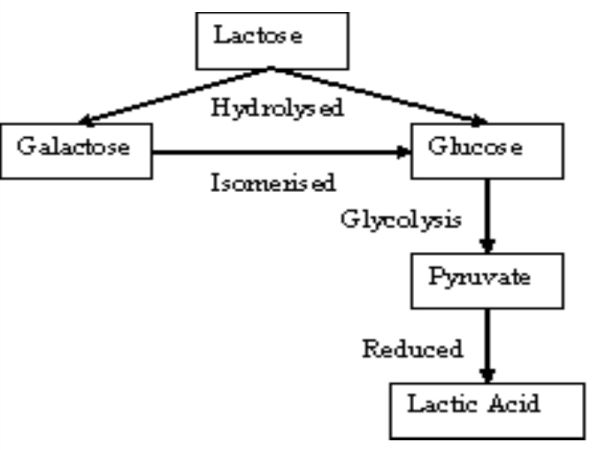

Lactose (milk sugar) consists of two simple sugars - glucose + galactose.

Chemical representation

Fun fact: Small intestine in human beings produces enzyme lactase, which breaks down lactose for easier digestion.

Usually a special “starter bacteria” is added to speed up the fermentation (conversion of starch or sugar or glucose into acid):

2 kinds of bacteria are used for this purpose: ·

- Mesophilic bacteria – grows best in room temperature 20 – 45 degree Celsius – used for mellow cheese: Cheddar, Gouda and Colby ·

- Thermophilic bacteria – loves thermos, grows in higher temperatures – used to make Gruyere, Parmesan, and Romano

Step 2 – Curdling of Milk – Rennet dance

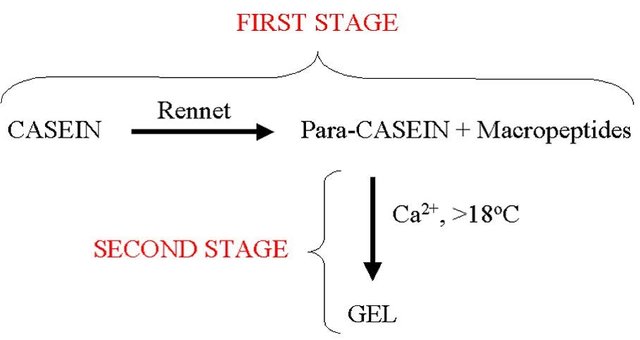

At the end of step 1, we have a thickened, soured milk. The next step is to separate Solid (Curd) from liquid (Whey) which is done using enzymes found in rennet. Rennet speeds up the coagulation or casein (milk protein) and produces a stronger curd, it also facilitates curdling at lower acidity.

“Rennet is a mixture containing active enzyme chymosin, can be considered as human’s first experiment with Biotechnology”

Rennet was first discovered in the stomachs of young animals possibly when stomachs of certain animals were used to carry milk around. ‘Vegetarian’ rennet is now produced in the laboratory.

The chemical process

Rennet acts only on milk proteins – casein protein. Casein occur in milk as clumps known as “micelles”, held together by Calcium. Micelles have negative charge on the surface, which make them repel each other so they are separated in the milk. Rennet helps in neutralization these negative charges and create a network of casein proteins.

“The chymosin in rennet breaks down the kappa casein on the surface of the micelles changing them from being hydrophilic to hydrophobic”

Step 3 – Releasing whey, Moulding and Pressing the Curd

Liquid whey is then removed by breaking the curd, the more whey is removed, the firmer the cheese will be. Traditionally this is usually done by pouring the Curd/ Whey mixture into a cheese cloth in the colander like mould. The Whey is drained away through the cheese cloth and with the help of little pressure over it.

“This process of moulding the cheese is critical: the shape of the mould, the application of pressure and the proportion of whey removed all have major effects on the final cheese, especially on its texture”

Example Moulds

For hard cheese like Cheddar: The curd is ‘milled’ or ‘cheddar’ by breaking the curd into several small pieces which helps in reducing the moisture content even further. Salt is added and heavy pressure is applied while moulding the cheese.

For softer cheese some whey is left with the curds. They have a moist, open airy texture to provide suitable conditions for mould to grow.

Step 4 - Ripening the Cheese

The lives of soft cheeses like Brie and Camembert are meteoric: their prime comes and goes within weeks. The white surface mould that characterises them produces an enzyme that penetrates the cheese, breaking down the casein protein network and transforming the chalky curd into the runny, smelly substance that we enjoy. Left too long, however, and the protein structure collapses into an unpalatable, stinky mess. For harder cheeses the ageing process is prolonged for a few months to a year, or even, for really dry cheeses like Parmesan, several years. With more time, the decay of the casein proteins allows more flavour-producing chemicals to form

Chemical Transformations

- Breaking down of protein into medium-sized pieces called peptides and then into smaller amino acids. These can in turn be broken down into various, highly flavoured molecules called amines. At each stage more complex flavours are produced. For example amines can have smells ranging from spoiling meat to sulphur-like smells, or even ammonia. Though these scarcely sound appetising, bare hints of them build the complexity and richness of cheeses' flavours and smells.

- Alongside the breaking down of proteins, fats can also be degraded, particularly by blue-cheese moulds such as P. roqueforti. These fats become fatty acids, which in turn become smaller molecules with many of the characteristic smells and flavours of blue cheeses. Some fatty acids have a peppery effect on the tongue and an intense sheep or goat aroma. The more diverse the cast of ripening enzymes, the more complex the resulting collection of protein and fat fragments and the richer the flavour. A flavour that is still of the land but has developed a life of its own.

Variants of Cheese

From the amount of rennet added, the way in which the rennet is added, the bacterial cultures used, and even the amount of salt used; there are many aspects of cheese making that set different types apart. The temperature that the cheese is aged in and the treating process of each cheese also effects the overall outcome of the cheese including its acidity, fat, moisture, protein, and level of calcium. There are seven identified cheese families as outlined by Professor Arthur Hill from the University of Guelph. In the following descriptions, which come directly from his article, “Introduction to Cheese Making,” he explains the basic differences in production that set each cheese family apart.

- Family 1: Acid-Coagulated Fresh Cheese. This family includes cottage cheese, quark and cream cheese and is coagulated by lactic acid produced by bacteria, with almost no contribution from rennet.

- Family 2: Rennet-Coagulated Fresh Cheese. This family, including Italian fresh cheese and halloumi, is coagulated entirely by rennet and the natural pH of the milk.

- Family 3: Heat-Acid Precipitated Cheese. In this family, coagulation occurs by heating the milk above 75°C which denatures the whey proteins and then acidifying by the addition of lactic or citric acid. This means that both casein and whey proteins are coagulated, creating a moist but firm cheese, such as ricotta or paneer cheese.

- Family 4: Soft Ripened Cheese. This family includes Brie, Camembert, feta and blue cheese. A large amount of lactic acid bacteria is added and ripened before the addition of rennet, increasing the quantity of acid produced. Additionally the setting time is increased.

- Family 5: Semi-Hard Washed Cheese - a large and diverse family including Gouda, Edam, Montasio and Oka. This cheese has the whey removed and replaced by water in order to remove lactose from the curd, which limits the amount of lactose, and hence the acidity of the cheese.

- Family 6: Low Temperature Hard Cheese. These cheeses, which include cheddar and Manchego cheeses, are characterized by lower moisture and the control of lactose content by fermentation.

- Family 7: High Temperature Hard Cheese. By reducing moisture content by high renneting and cooking temperature, romano, Parmesan and Swiss Cheese are produced.

Conclusion:Did you ever wonder that your favorite cheese is actually a decayed milk :)Hope you enjoyed reading

__________________________________________________________________________

Sources and further reading:

https://www.sciencelearn.org.nz/resources/827-the-science-of-cheese https://www.theguardian.com/science/blog/2010/jan/05/science-cheesemaking-cheese https://cultivationofacheesemonger.wordpress.com/2012/10/29/lactose-free-cheese/ http://artandscienceofcheese.blogspot.in/2012/03/chemistry-of-cheese-part-2.html __________________________________________________________________________

Thank you for readingFor the love of Cheesy Cheese, please support with your upvotes

One question remains unanswered: When cheese gets its picture taken, what does it say?

Otherwise great post :)