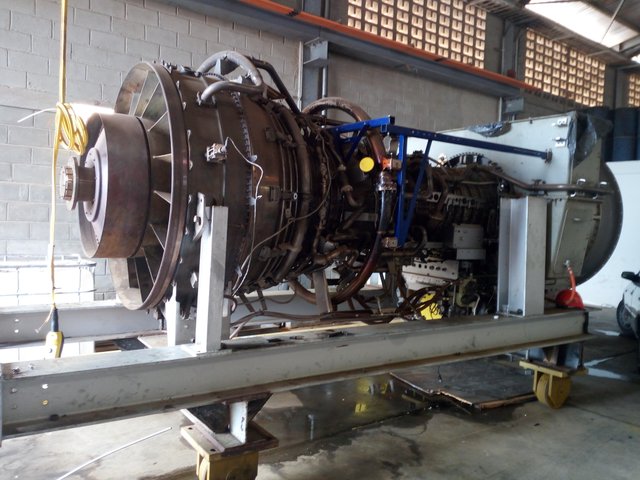

Turbogenerators

Gas turbines are turbomachines that generally belong to the group of thermal generating machines and whose operating range ranges from small powers (30 KW for microturbines) to 500 MW for the latest developments. In this way, they compete both with alternative engines (OTTO and DIESEL thermodynamic cycles) and with small and medium power steam installations.

Image taken by me

Its main advantages are its small weight and volume in relation to its power and the flexibility of its operation. This makes them machines whose use for certain applications, especially those related to electricity generation and propulsion of ships and aircraft, is clearly increasing. As they are rotary machines, they have a clear advantage over alternative engines, due to the absence of alternative movements and friction between solid surfaces (such as between piston and cylinder liner), which translates into fewer balancing problems and lower lubricating oil consumption, which are also not in contact with hot surfaces or combustion products.

Compared to steam turbines, gas turbines have hardly any cooling needs, which greatly facilitates their installation. In addition, their low thermal inertia allows them to reach their full load in very short times, making them ideal for certain applications where rapid load variations are required (grid regulation or supply of demand peaks).

This simplicity compared to steam turbines and alternative engines gives gas turbines two additional advantages: simple maintenance compared to other thermal machines and high reliability. Indeed, the reduction in lubrication and cooling requirements, the continuity of the combustion process and the absence of alternative movements reduce the probability of failure. An electrical generation installation based on a gas turbine can easily reach availability values above 95% and reliability values close to 99% if the installation is well designed, well constructed, well operated and with an adequate level of maintenance

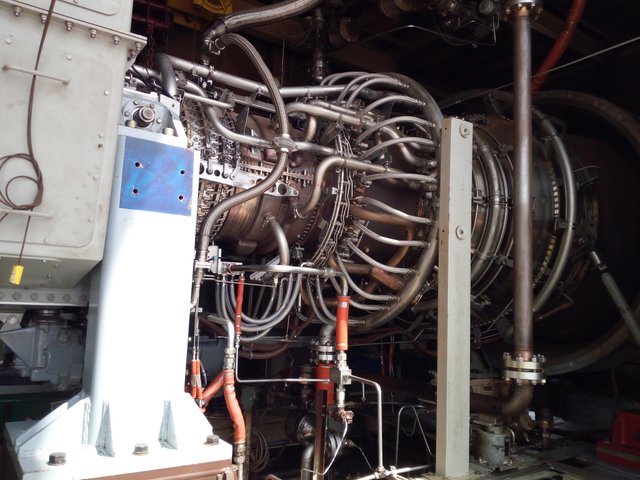

Image taken by me

However, they also have some important drawbacks, among which two stand out: high rotation speed and low efficiency (30-35%) compared with alternative diesel engines (some developments already reach 50% efficiency) or with steam turbines (40% values are very normal).

A gas turbine is normally understood to be the set made up of the following elements:

Compressor, responsible for raising the pressure of the working fluid.

System of heat contribution to the fluid.

Expander element, or turbine itself.

Its applications are very varied, being its field of application the widest among thermal engines. Initially they were used for the accomplishment of mechanical work. Later they were moved to the field of aeronautics as a propellant element, especially after the Second World War. Later they were used as a driving element for the generation of electrical energy, an application for which specific models have been developed that have tried to adapt to the demands of this market. The possibility of taking advantage of the heat of the exhaust gases to produce steam that can be used in industry as thermal energy or to produce more electrical energy (in the so-called combined gas-steam cycles) has led to a real revolution in the electricity generation market, where the steam turbine has been the undisputed queen for many years.

Image taken by me

A gas turbine is a rotary internal combustion engine, where from the energy provided by a fuel mechanical energy is produced and a significant amount of heat is generated in the form of hot gases with a high percentage of oxygen.

Image taken by me

The thermal cycle represented by this machine is the Brayton cycle. The machine follows an open cycle, since the fluid that passes through it is continuously renewed. The air is sucked from the atmosphere and compressed and then passed to the combustion chamber, where it is mixed with the fuel and ignition takes place. The hot gases, the product of combustion, flow through the turbine. There they expand and move the shaft, which drives the turbine compressor and the alternator.

Posted from my blog with SteemPress : https://automation80.000webhostapp.com/2019/07/turbogenerators

Congratulations @automation80! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!